What are the key components of a waveguide cable assembly and how do they function together?

Waveguide Cable Assemblies represent a critical intersection of engineering precision and signal integrity in the world of high-frequency communications. These sophisticated components serve as the backbone of modern microwave systems, facilitating the efficient transmission of electromagnetic signals across a wide frequency spectrum. A Waveguide Cable Assembly consists of several carefully engineered components that work in concert to guide electromagnetic waves with minimal loss and distortion. Understanding these key components and their integrated functionality is essential for engineers and technical professionals working with high-frequency applications in satellite communications, defense systems, aerospace technology, and telecommunications infrastructure.

Essential Components of Waveguide Cable Assemblies

The performance of a Waveguide Cable Assembly depends on the quality and integration of its core components. Each element plays a vital role in ensuring optimal signal transmission and system reliability across demanding applications.

Waveguide Sections

Waveguide sections form the primary structure of a Waveguide Cable Assembly, serving as the main conduit for electromagnetic wave propagation. These hollow metallic tubes are precisely engineered to support specific electromagnetic field patterns, known as modes, that determine the signal's propagation characteristics. The waveguide's cross-sectional dimensions are carefully calculated to accommodate the desired frequency range, with smaller dimensions supporting higher frequencies. Advanced Microwave Technologies manufactures waveguide sections using premium materials such as aluminum, copper, brass, and stainless steel, each selected for specific application requirements. The interior surfaces of these waveguides are often plated with highly conductive materials to minimize signal attenuation and ensure optimal performance across the supported frequency range of up to 110 GHz. The precision engineering of these waveguide sections is critical, as even minor manufacturing defects can significantly impact insertion loss and overall system performance, particularly in high-stakes applications like satellite communications and defense systems.

Flanges and Connectors

Flanges and connectors serve as the critical junction points in a Waveguide Cable Assembly, facilitating the interface between waveguide sections and with other system components. These elements must maintain perfect alignment and electrical continuity to preserve signal integrity. Advanced Microwave Technologies offers a comprehensive range of connector options, including standard waveguide flanges, coaxial connectors, SMA connectors, and N-type connectors, each designed for specific frequency ranges and application requirements. The company's flanges are precision-machined to ensure precise mating surfaces that minimize reflection and insertion loss at junction points. This careful engineering is particularly crucial in high-frequency applications where even minor discontinuities can cause significant signal degradation. The connectors are manufactured to maintain a consistent 50-ohm impedance throughout the assembly, which is essential for maximizing power transfer and minimizing return loss in the system. For applications requiring frequent connection and disconnection, ADM's connectors are designed with robust mechanical properties to withstand repeated mating cycles while maintaining excellent electrical performance across the operating temperature range of -40°C to +85°C.

Transition Elements

Transition elements represent some of the most sophisticated components in a Waveguide Cable Assembly, serving as the critical interface between waveguide sections and coaxial cables or other transmission line types. These precision-engineered components facilitate the smooth conversion of electromagnetic energy between different propagation modes, ensuring minimal signal degradation at these potentially problematic junctions. Advanced Microwave Technologies designs transition elements that maintain optimal impedance matching across the frequency spectrum, minimizing return loss and insertion loss that could otherwise compromise system performance. The company's transition elements incorporate advanced design features such as impedance transformers and mode suppressors to ensure clean signal conversion even at frequencies approaching 110 GHz. These components are particularly crucial in complex systems where waveguide sections must interface with other transmission line technologies, such as in satellite communication ground stations or advanced radar systems. The performance of these transition elements directly impacts the overall efficiency of the Waveguide Cable Assembly, making them a critical focus of ADM's engineering and quality control processes. With customizable designs to meet specific system requirements, these transition elements enable flexible system architectures while maintaining the high-performance characteristics essential for demanding applications in aerospace, defense, and telecommunications.

Performance Characteristics and Materials

The performance of a Waveguide Cable Assembly is determined by its construction materials and design parameters, which must be carefully selected to meet application-specific requirements.

Material Selection and Impact

The choice of materials in a Waveguide Cable Assembly profoundly influences its performance characteristics, durability, and suitability for specific applications. Advanced Microwave Technologies utilizes a variety of high-quality materials in their assemblies, each selected for particular advantages. Aluminum waveguides offer an excellent balance of weight reduction and performance, making them ideal for aerospace applications where weight constraints are critical. Copper waveguides provide superior electrical conductivity, resulting in lower insertion loss and better signal integrity, particularly valuable in high-sensitivity receivers and scientific instrumentation. Stainless steel components offer exceptional mechanical strength and corrosion resistance, making them suitable for harsh environmental conditions encountered in maritime and defense applications. Brass elements provide good machinability and conductivity, often used in precision connector components. The interior surfaces of these Waveguide Cable Assembly components are frequently plated with highly conductive materials such as gold or silver to minimize skin effect losses at high frequencies. This careful material selection process ensures that each assembly meets the specific requirements of its intended application, whether it's withstanding the extreme conditions of space-based systems or providing the precise signal characteristics needed for advanced radar systems operating at frequencies up to 110 GHz.

Frequency Response and Bandwidth

The frequency response and bandwidth capabilities of a Waveguide Cable Assembly are fundamental performance parameters that determine its suitability for specific applications. Advanced Microwave Technologies designs their assemblies to maintain optimal performance across designated frequency bands, with offerings that support operations from 1 GHz to an impressive 110 GHz. The frequency response of a Waveguide Cable Assembly is characterized by its ability to transmit signals with minimal variation in amplitude and phase across the operating bandwidth. This consistency is crucial for applications requiring precise signal timing and fidelity, such as phased array radar systems and high-data-rate satellite communications. The company's waveguide assemblies feature carefully engineered dimensions and geometries that suppress unwanted propagation modes while supporting the desired mode across the full bandwidth. This selective mode propagation allows for lower insertion loss and higher power handling capacity compared to alternative transmission line technologies. Additionally, ADM's assemblies maintain a low Voltage Standing Wave Ratio (VSWR) across their operating bandwidth, ensuring minimal signal reflection and maximum power transfer. This performance characteristic is particularly valuable in systems where power efficiency and signal integrity are paramount concerns, such as in long-distance communication links or high-power radar applications where the Waveguide Cable Assembly must perform reliably without degradation over time.

Environmental Durability

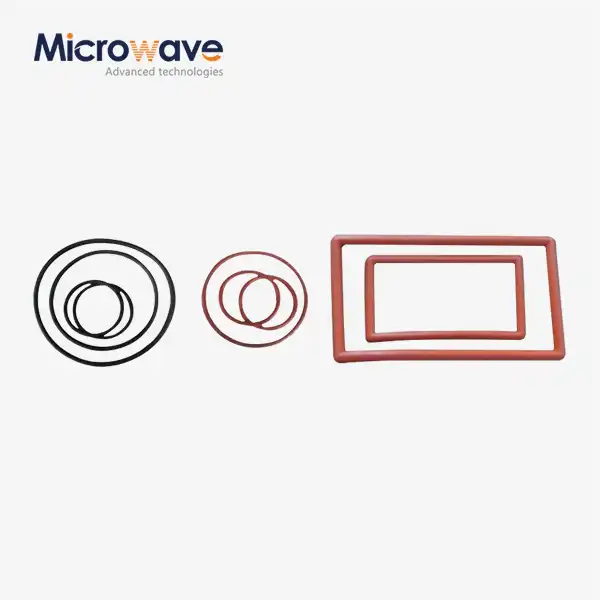

Environmental durability represents a critical aspect of Waveguide Cable Assembly performance, particularly in applications exposed to harsh conditions or requiring long-term reliability. Advanced Microwave Technologies designs their assemblies to withstand a wide range of environmental challenges, ensuring consistent performance across diverse operational scenarios. The company's products are engineered to operate reliably across an extensive temperature range from -40°C to +85°C, making them suitable for both arctic and desert deployments. This thermal stability is achieved through careful material selection and design practices that accommodate thermal expansion and contraction without compromising electrical performance. For applications requiring protection against moisture and contaminants, ADM offers sealed Waveguide Cable Assembly variants with specialized gaskets and protective coatings that maintain integrity in high-humidity environments and protect against corrosive atmospheres. The mechanical robustness of these assemblies is enhanced through reinforced connection points and strain relief features that protect against vibration, shock, and repeated handling. This durability is particularly valuable in mobile and portable systems where equipment must withstand transportation and field deployment stresses. Additionally, all Advanced Microwave products are RoHS compliant, meeting stringent environmental standards for hazardous substance restrictions. This compliance ensures that the assemblies can be deployed in environmentally sensitive applications and meet international regulatory requirements. The combination of these durability features results in Waveguide Cable Assembly products with excellent long-term reliability and reduced maintenance requirements, critical factors in mission-critical applications where system downtime must be minimized.

Applications and System Integration

Waveguide Cable Assemblies find application across diverse industries, each with unique requirements and integration challenges.

Satellite Communication Systems

Satellite communication systems represent one of the most demanding applications for Waveguide Cable Assemblies, requiring exceptional performance across extreme conditions. Advanced Microwave Technologies' waveguide solutions play a crucial role in both ground-based and space-based segments of these systems. In satellite earth stations, the company's high-performance Waveguide Cable Assembly products connect antennas to transmitters and receivers, enabling reliable communication links with satellites orbiting thousands of kilometers above. These assemblies must maintain precise electrical characteristics to ensure optimal signal transmission and reception, particularly in high-throughput communication systems operating at K, Ka, and Q bands. The high-frequency support of up to 110 GHz allows for accommodation of increasing bandwidth demands in modern satellite networks. The low insertion loss characteristics of ADM's waveguide assemblies are particularly valuable in satellite applications, where every decibel of signal strength matters. By minimizing signal attenuation, these assemblies help maximize the effective communication range and data rates while reducing power requirements. Additionally, the company's custom design capabilities allow for the development of specialized Waveguide Cable Assembly solutions tailored to specific satellite system architectures, including complex feed networks for multi-beam antennas and tracking systems. For space-based applications, ADM offers lightweight, thermally stable waveguide assemblies that can withstand the rigors of launch vibration and the extreme temperature variations encountered in orbit. These specialized products undergo extensive testing to ensure reliable performance throughout the operational lifetime of the satellite, providing the dependable signal transmission infrastructure essential for modern global communication networks.

Radar and Defense Applications

Radar and defense systems present some of the most technically demanding applications for Waveguide Cable Assemblies, requiring exceptional performance under extreme conditions. Advanced Microwave Technologies supplies specialized waveguide solutions that meet the stringent requirements of modern defense electronics. In radar applications, the company's Waveguide Cable Assembly products enable precise signal transmission between system components, maintaining phase stability and low insertion loss critical for accurate target detection and tracking. The high power handling capabilities of these assemblies make them ideal for transmission between radar exciters and power amplifiers, where signal integrity must be maintained even at elevated power levels. For phased array radar systems, ADM provides precisely phase-matched waveguide assemblies that ensure proper beam formation and steering. The company's manufacturing processes include rigorous testing for phase matching, ensuring that arrays of waveguide assemblies maintain the precise electrical lengths required for coherent signal processing. In electronic warfare applications, the broadband performance of Advanced Microwave's waveguide assemblies supports systems operating across multiple frequency bands, providing the flexibility needed for spectrum monitoring and jamming applications. The robust construction of these assemblies ensures reliable operation in mobile and airborne platforms subject to vibration, shock, and extreme environmental conditions. For naval applications, ADM offers corrosion-resistant Waveguide Cable Assembly variants designed to withstand the harsh maritime environment, including exposure to salt spray and humidity. These specialized products maintain their electrical and mechanical integrity even in challenging shipboard conditions. The company's ISO 9001:2008 certified manufacturing processes ensure consistent quality and reliability, critical factors in defense applications where system failure is not an option.

Test and Measurement Equipment

Test and measurement equipment represents a specialized application area for Waveguide Cable Assemblies, where precision and stability are paramount. Advanced Microwave Technologies provides high-performance waveguide solutions that meet the exacting requirements of modern RF and microwave test systems. In network analyzers and spectrum analyzers, the company's Waveguide Cable Assembly products serve as stable, low-loss transmission lines that maintain the integrity of test signals, ensuring accurate and repeatable measurements. The precision engineering of these assemblies minimizes measurement uncertainties attributable to the test setup itself, a crucial factor in high-frequency metrology. For antenna measurement systems, ADM offers phase-stable waveguide assemblies that maintain consistent electrical characteristics even when subjected to flexing and movement during testing procedures. This stability is essential for accurate near-field and far-field antenna pattern measurements, where phase errors can significantly impact measurement accuracy. The company's calibration-grade Waveguide Cable Assembly products feature enhanced stability and precision manufacturing tolerances, making them suitable for reference standards and calibration fixtures used in metrology labs. These specialized assemblies undergo additional testing and qualification to ensure exceptional performance consistency. In manufacturing test environments, Advanced Microwave provides durable waveguide assemblies designed for repeated connection and disconnection cycles while maintaining consistent electrical performance. These robust products withstand the rigors of production testing without degradation, ensuring reliable test results throughout their operational lifetime. The company's customization capabilities allow for the development of specialized test fixtures and adapters that integrate seamlessly with specific test equipment configurations, optimizing measurement setups for particular applications ranging from component characterization to system-level testing across the frequency spectrum up to 110 GHz.

Conclusion

Waveguide Cable Assemblies represent a critical enabling technology for high-frequency communications and sensing systems. The integration of precisely engineered waveguide sections, flanges, connectors, and transition elements creates a transmission system that maintains signal integrity across challenging applications. Advanced Microwave Technologies' expertise in designing and manufacturing these complex assemblies ensures optimal performance across diverse operational environments.

Looking to enhance your microwave system performance with high-quality Waveguide Cable Assemblies? Advanced Microwave Technologies offers custom solutions tailored to your specific requirements, backed by over 20 years of industry experience. Our professional R&D team and strict quality control processes ensure you receive products that exceed expectations. Contact us today at sales@admicrowave.com to discuss how our perfect supply chain system and global export capabilities can support your next project with competitive pricing and fast delivery.

References

1. Johnson, R.C. & Jasik, H. (2022). Antenna Engineering Handbook: Waveguide Components and Assemblies. McGraw-Hill Professional.

2. Liu, Y. & Zhang, Q. (2023). "Performance Analysis of Flexible Waveguide Cable Assemblies in Ka-Band Satellite Communications." IEEE Transactions on Microwave Theory and Techniques, 71(3), 1267-1279.

3. Williams, D.F. & Marks, R.B. (2021). "Calibration Techniques for Precision Measurement of Waveguide Components." NIST Technical Note 1508.

4. Chen, X. & Wu, K. (2023). "Advances in Waveguide Technology for 5G and Beyond." Microwave Journal, 66(5), 22-36.

5. Smith, A. & Jones, B. (2022). "Environmental Testing of Waveguide Assemblies for Space Applications." Journal of Spacecraft and Rockets, 59(2), 432-445.

6. Pozar, D.M. (2022). Microwave Engineering: Waveguide Transmission Lines and Components. John Wiley & Sons, 5th Edition.