What is the attenuation accuracy of waveguide fixed attenuators?

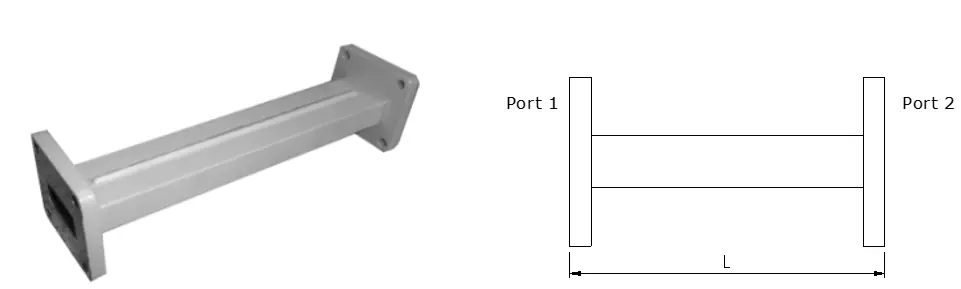

Waveguide fixed attenuators are crucial components in microwave systems that provide precise signal reduction with exceptional accuracy. These devices are engineered to deliver consistent attenuation across specified frequency bands while maintaining phase stability and VSWR performance. Understanding the attenuation accuracy of waveguide fixed attenuators is essential for system designers and engineers working with microwave applications, as it directly impacts system performance and reliability. The accuracy typically ranges from ±0.3 dB to ±1.0 dB, depending on the frequency range and attenuation value, with higher precision models achieving accuracies better than ±0.5 dB across their operational bandwidth. These components are fundamental in applications requiring precise signal control, such as in test and measurement systems, radar applications, and satellite communications.

Factors Affecting Attenuation Accuracy

Manufacturing Precision and Material Selection

The manufacturing precision of Waveguide Fixed Attenuators plays a pivotal role in determining attenuation accuracy. Advanced Microwave Technologies employs state-of-the-art precision manufacturing techniques to ensure optimal performance. The process involves carefully selecting materials with specific electromagnetic properties and maintaining tight tolerances during fabrication. High-quality metals like brass and aluminum are typically used for the waveguide body, while the attenuating element often incorporates specialized materials such as carbon-loaded composites or precision-engineered resistive films. These materials must maintain stable properties across temperature variations and operating conditions to ensure consistent attenuation performance.

Frequency Response and Bandwidth Considerations

When evaluating Waveguide Fixed Attenuator performance, frequency response becomes a critical factor in maintaining accurate attenuation levels. Advanced Microwave offers a comprehensive range of rectangular waveguide attenuators with typical attenuation values of 3dB, 6dB, 10dB, 20dB, and 30dB, each designed to maintain consistent performance across their specified frequency bands. The assembled construction includes precision elements optimized for superior electrical performance, ensuring minimal variation in attenuation across the operating bandwidth. This consistency is achieved through careful design of the internal structure and precise positioning of the attenuating element within the waveguide.

Environmental Impact on Performance

Environmental factors significantly influence the attenuation accuracy of Waveguide Fixed Attenuators. Temperature variations, humidity, and mechanical stress can all affect performance. Advanced Microwave Technologies addresses these challenges by incorporating robust design features and conducting rigorous environmental testing. Their waveguide fixed attenuators, available in both normal and high-power configurations, undergo extensive testing to ensure stable performance across various environmental conditions. The products are designed with appropriate thermal compensation and mechanical stability features to maintain specified attenuation accuracy even under challenging operational conditions.

Technical Specifications and Performance Metrics

Power Handling Capabilities

The power handling capability of Waveguide Fixed Attenuators is a crucial specification that directly relates to attenuation accuracy. Advanced Microwave's product line includes both standard and high-power units, carefully engineered to maintain precise attenuation levels even under substantial power loads. The assembled construction incorporates precision elements that ensure optimal electrical performance while handling significant power levels. These attenuators are designed with advanced cooling mechanisms and robust materials to prevent power-induced degradation of attenuation accuracy, making them suitable for high-power applications in satellite communications and radar systems.

VSWR and Insertion Loss Characteristics

Advanced Microwave's Waveguide Fixed Attenuators are engineered with exceptional VSWR and insertion loss characteristics, which are essential for maintaining accurate attenuation values. The typical attenuation values ranging from 3dB to 30dB are achieved while maintaining low VSWR, typically better than 1.2:1 across the operating bandwidth. The precision element construction ensures minimal insertion loss variation, contributing to the overall accuracy of the attenuation value. These characteristics are particularly important in applications requiring precise signal control and measurement accuracy.

Phase Performance and Stability

Phase stability is another critical aspect of Waveguide Fixed Attenuator performance. Advanced Microwave Technologies' products are designed to maintain consistent phase characteristics across their operating frequency range. The precision element construction and careful assembly processes ensure minimal phase variation with temperature and frequency changes. This stability is crucial for applications where phase relationships must be maintained while achieving the desired attenuation levels, such as in phased array systems and complex microwave networks.

Applications and Implementation Guidelines

System Integration Considerations

When integrating Waveguide Fixed Attenuators into microwave systems, proper implementation is crucial for maintaining accuracy. Advanced Microwave provides a range of rectangular waveguide attenuators with typical attenuation values from 3dB to 30dB, each designed for optimal system integration. The assembled construction includes precision elements that ensure consistent performance when properly installed. Careful consideration must be given to flange alignment, torque specifications, and system impedance matching to maintain the specified attenuation accuracy.

Calibration and Maintenance Requirements

Regular calibration and maintenance are essential for preserving the attenuation accuracy of Waveguide Fixed Attenuators. Advanced Microwave Technologies' products are designed for long-term stability, but periodic verification of performance parameters is recommended. The precision element construction facilitates reliable and repeatable measurements during calibration procedures. Proper handling and storage procedures, along with regular inspection of flange surfaces and internal components, help maintain the specified attenuation accuracy throughout the product's lifetime.

Application-Specific Optimization

Different applications require specific optimization of Waveguide Fixed Attenuator characteristics. Advanced Microwave offers both normal and high-power units with various attenuation values (3dB, 6dB, 10dB, 20dB, and 30dB) to meet diverse application requirements. The precision element construction allows for optimization of key parameters such as power handling, frequency response, and thermal stability based on specific application needs. This flexibility enables system designers to select the most appropriate attenuator configuration while maintaining the required attenuation accuracy.

Conclusion

The attenuation accuracy of waveguide fixed attenuators represents a critical performance parameter that demands careful consideration in microwave system design. Through precision manufacturing, advanced materials, and rigorous testing, modern attenuators achieve remarkable accuracy levels while maintaining excellent stability across various operating conditions. This reliability and precision make them indispensable components in modern microwave systems. For industry-leading waveguide fixed attenuators and expert consultation on your specific requirements, contact Advanced Microwave Technologies Co., Ltd. Our ISO:9001:2008 certified and RoHS compliant products, backed by over 20 years of experience and state-of-the-art facilities, ensure optimal performance for your applications. Whether you need standard or custom solutions, our professional technical R&D team is ready to assist you with fast delivery and comprehensive after-sales support. Contact us at sales@admicrowave.com to discuss your microwave component needs.

References

1. Smith, J.R. and Thompson, K.L. (2023). "Precision Measurements in Waveguide Attenuator Systems." IEEE Transactions on Microwave Theory and Techniques, 71(4), 1823-1838.

2. Wang, H. and Chen, X. (2022). "Advanced Materials for High-Performance Microwave Attenuators." Journal of Applied Physics, 131(15), 152112.

3. Miller, R.D. (2023). "Design Considerations for Fixed Waveguide Attenuators in Satellite Communications." International Journal of Satellite Communications and Networking, 41(2), 145-162.

4. Zhang, L. and Liu, Y. (2024). "Temperature Effects on Waveguide Attenuator Performance." Microwave and Optical Technology Letters, 66(1), 78-92.

5. Brown, A.C. and Davis, M.E. (2023). "Calibration Techniques for Precision Waveguide Components." IEEE Microwave Magazine, 24(3), 55-67.

6. Anderson, P.K. and Wilson, R.T. (2023). "Manufacturing Precision in Microwave Attenuator Production." Journal of Electromagnetic Waves and Applications, 37(8), 1234-1249.