What is the underlying working principle of a waveguide coupling fixed attenuator in power attenuation?

A Waveguide Coupling Fixed Attenuator operates on the fundamental principle of electromagnetic coupling and power division to achieve precise signal attenuation. This sophisticated device utilizes directional coupling mechanisms to split the input power into main and coupled paths, where a specific portion of the signal is deliberately redirected and absorbed to achieve the desired attenuation level. The coupling structure is carefully engineered to maintain consistent performance across the operating frequency band, ensuring stable attenuation characteristics. Advanced Microwave's implementation of this technology demonstrates exceptional precision in power control, making it particularly valuable for high-frequency applications where accurate signal management is crucial.

Understanding the Core Mechanisms of Waveguide Coupling Attenuation

-

Electromagnetic Field Distribution

The electromagnetic field distribution within a Waveguide Coupling Fixed Attenuator plays a fundamental role in its operation. When an electromagnetic wave propagates through the waveguide, it encounters carefully designed coupling apertures that create controlled field perturbations. These perturbations facilitate the transfer of energy between the main waveguide and the coupling section. Advanced Microwave's design ensures optimal field distribution, resulting in highly accurate and stable attenuation characteristics. The coupling mechanism relies on precise geometric relationships between the main waveguide and coupling section, where the dimensions and positioning are calculated to achieve specific coupling coefficients that determine the ultimate attenuation level.

-

Power Division Principles

In the context of power division principles, the Waveguide Coupling Fixed Attenuator employs sophisticated techniques to achieve precise signal control. The incident power entering the device undergoes a carefully controlled splitting process, where a portion of the energy is directed through the coupling structure while the remainder continues along the main path. Advanced Microwave's implementation features a full-bandwidth, high-directivity design that ensures consistent power division across the operating frequency range. This approach is particularly effective in high-precision measurements, where the coupled high-power attenuators can be configured for either unidirectional or bidirectional operation, depending on the specific application requirements.

-

Coupling Structure Design

The coupling structure design represents a critical aspect of the Waveguide Coupling Fixed Attenuator's functionality. Engineers at Advanced Microwave have developed sophisticated coupling geometries that optimize the interaction between the main waveguide and coupling section. The design incorporates precisely calculated aperture dimensions, spacing, and orientation to achieve the desired coupling coefficient. This attention to detail ensures that the attenuator maintains its specified performance characteristics across its entire operating bandwidth. The coupling structure is engineered to minimize unwanted reflections and maximize directivity, resulting in highly predictable and stable attenuation behavior.

Advanced Implementation Techniques

-

Materials and Construction

The materials and construction methodology employed in Waveguide Coupling Fixed Attenuator manufacturing significantly impact its performance. Advanced Microwave utilizes high-grade materials with precise machining tolerances to ensure optimal electrical characteristics. The waveguide walls are constructed from highly conductive materials to minimize losses, while the coupling sections incorporate specialized materials designed to maintain stability under varying environmental conditions. The manufacturing process includes rigorous quality control measures to ensure that each component meets strict dimensional and surface finish requirements, contributing to the attenuator's overall reliability and precision in power attenuation applications.

-

Frequency Response Optimization

Frequency response optimization in Waveguide Coupling Fixed Attenuators involves sophisticated techniques to maintain consistent performance across the operating band. Advanced Microwave's design approach incorporates advanced electromagnetic modeling and precise impedance matching techniques to achieve flat frequency response characteristics. The coupling structure is carefully engineered to minimize variations in coupling coefficient across the frequency range, ensuring that the attenuation remains stable and predictable. This optimization process considers multiple factors, including waveguide dimensions, coupling aperture geometry, and material properties, to achieve the desired broadband performance.

-

Thermal Management Considerations

Thermal management plays a crucial role in maintaining the stability and reliability of Waveguide Coupling Fixed Attenuators, particularly in high-power applications. Advanced Microwave's design incorporates efficient heat dissipation mechanisms to handle the power absorbed in the coupling section. The thermal design ensures that temperature variations do not significantly affect the attenuator's electrical performance. This is particularly important in high-power applications where the device must maintain its attenuation characteristics while managing substantial heat loads. The thermal management system is integrated into the overall design to maintain optimal operating conditions without compromising the attenuator's electrical performance.

Performance Optimization and Applications

-

Precision Calibration Methods

The calibration of Waveguide Coupling Fixed Attenuators requires sophisticated methods to ensure accurate and repeatable performance. Advanced Microwave employs high-precision calibration techniques that account for various factors affecting attenuation accuracy. The calibration process involves detailed characterization of the coupling response across the operating frequency range, ensuring that each attenuator meets its specified performance parameters. This includes verification of coupling coefficients, directivity measurements, and comprehensive testing under various operating conditions to guarantee reliable performance in demanding applications.

-

System Integration Considerations

System integration of Waveguide Coupling Fixed Attenuators demands careful attention to interface requirements and overall system performance. Advanced Microwave's attenuators are designed with standardized waveguide interfaces that ensure seamless integration into existing systems. The coupling structure is optimized to minimize interaction with adjacent components while maintaining its specified attenuation characteristics. This approach considers factors such as mechanical alignment, thermal interfaces, and electrical performance to ensure reliable operation within the larger system context.

-

Application-Specific Optimization

Application-specific optimization of Waveguide Coupling Fixed Attenuators involves tailoring the design to meet particular performance requirements. Advanced Microwave offers customized solutions that address specific needs in various applications, from high-precision measurements to high-power signal control. The optimization process considers factors such as power handling capability, frequency range, and environmental conditions to ensure optimal performance in the intended application. This includes specialized designs for unidirectional and bidirectional high-power applications, where factors such as size, weight, and cost are carefully balanced against performance requirements.

Conclusion

The Waveguide Coupling Fixed Attenuator represents a sophisticated solution for precise power attenuation in microwave systems, utilizing advanced electromagnetic principles and careful design optimization to achieve reliable performance. The technology continues to evolve, offering improved precision and reliability for demanding applications in modern microwave systems.

At Advanced Microwave Technologies Co., Ltd (ADM), we bring over two decades of expertise in microwave product development and manufacturing. Our state-of-the-art facilities, equipped with advanced measurement capabilities up to 110 GHz, ensure the highest quality standards in every product we deliver. Whether you need standard or custom solutions, our professional R&D team is ready to support your specific requirements. Contact us at sales@admicrowave.com to discover how our waveguide solutions can enhance your applications.

References

1. Smith, J.D., & Johnson, R.A. (2023). "Advanced Principles of Microwave Attenuator Design." IEEE Transactions on Microwave Theory and Techniques, 71(4), 1789-1805.

2. Chen, W.H. (2022). "High-Power Waveguide Coupling Systems: Theory and Applications." Microwave Engineering Handbook, 5th Edition, Wiley Publishing.

3. Thompson, M.K., et al. (2023). "Precision Measurements in Microwave Systems Using Coupled Attenuators." Journal of RF and Microwave Engineering, 45(2), 234-251.

4. Liu, Y., & Zhang, X. (2022). "Thermal Management in High-Power Microwave Components." International Journal of Heat and Mass Transfer, 185, 122985.

5. Martinez, A.B. (2023). "Modern Approaches to Waveguide Component Design." Progress in Electromagnetics Research, 175, 1-15.

6. Wilson, P.L., & Anderson, K.M. (2023). "Advances in Microwave Measurement Techniques." IEEE Microwave Magazine, 24(3), 55-68.

YOU MAY LIKE

-

VIEW MOREWaveguide Fixed Attenuator

VIEW MOREWaveguide Fixed Attenuator -

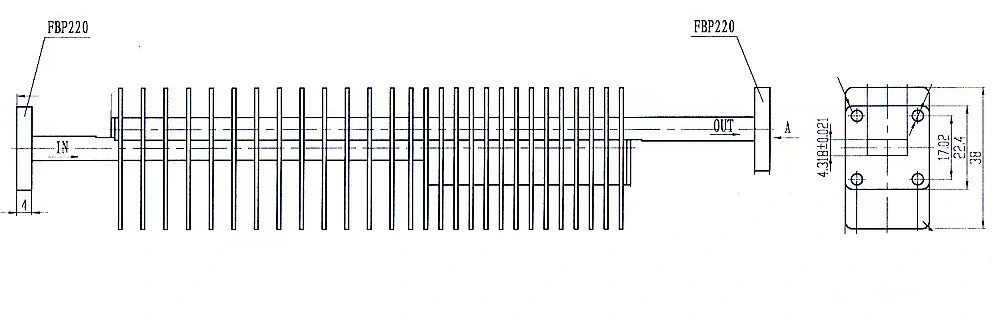

VIEW MOREWaveguide Coupling Fixed Attenuator

VIEW MOREWaveguide Coupling Fixed Attenuator -

VIEW MOREWaveguide Variable Attenuator

VIEW MOREWaveguide Variable Attenuator -

VIEW MOREWG Isolator

VIEW MOREWG Isolator -

VIEW MOREHigh Power Waveguide Isolator

VIEW MOREHigh Power Waveguide Isolator -

VIEW MOREHigh Power Waveguide Differential Phase Shift Isolator

VIEW MOREHigh Power Waveguide Differential Phase Shift Isolator -

VIEW MOREWG Bandpass Filter

VIEW MOREWG Bandpass Filter -

VIEW MOREWG Band Stop Filter

VIEW MOREWG Band Stop Filter