How does a Water-Cooled Twist Waveguide compare to a standard waveguide?

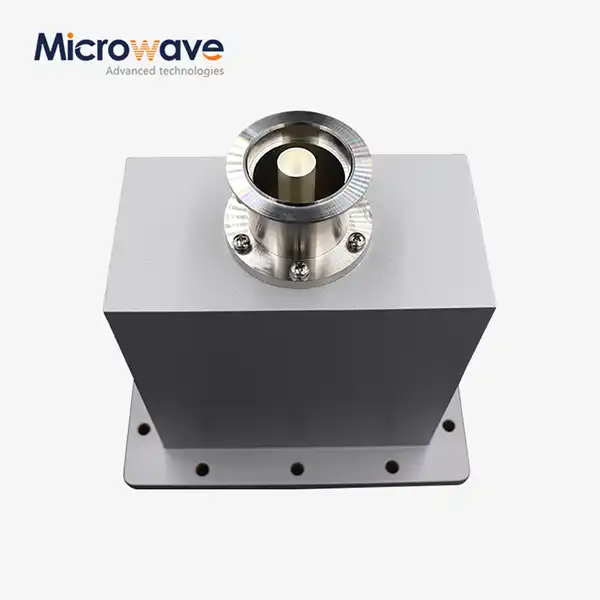

In the realm of microwave technology, the evolution of waveguide systems has led to significant advancements in power handling capabilities and operational efficiency. The Water-cooled Twist Waveguide represents a sophisticated enhancement over standard waveguides, specifically designed to address the challenges of high-power microwave transmission. This innovative solution incorporates an integrated cooling system that fundamentally transforms the way we manage thermal loads in microwave applications, offering superior performance characteristics and extended operational lifespans compared to conventional waveguide systems.

Performance Advantages of Water-Cooled Twist Waveguides

Enhanced Thermal Management Capabilities

The Water-cooled Twist Waveguide produced by Advanced Microwave incorporates a sophisticated cooling system that sets it apart from standard waveguides. The integration of water-cooling channels allows for continuous circulation of coolant throughout the waveguide structure, effectively dissipating heat generated during high-power operations. This advanced thermal management system enables the waveguide to maintain optimal operating temperatures even under extreme conditions, preventing performance degradation and potential system failures that might occur in standard waveguides. The carefully engineered cooling channels ensure uniform temperature distribution, minimizing thermal stress and maintaining consistent electromagnetic properties throughout the waveguide structure.

Superior Power Handling Capacity

In high-power microwave applications, the Water-cooled Twist Waveguide demonstrates exceptional performance capabilities that significantly exceed those of standard waveguides. The integrated cooling system allows these advanced components to handle power levels that would be prohibitive for conventional waveguides. Through the implementation of precision-engineered water cooling channels, these waveguides can effectively manage the thermal loads associated with high-power transmission while maintaining signal integrity. This enhanced power handling capacity makes them particularly valuable in applications such as radar systems, satellite communications, and industrial microwave processing, where maintaining stable operation under high-power conditions is crucial.

Extended Operational Lifespan

The incorporation of water cooling technology in twist waveguides significantly extends their operational lifespan compared to standard waveguides. The efficient heat dissipation provided by the water cooling system prevents thermal degradation of the waveguide materials and maintains the structural integrity of the component over extended periods of high-power operation. This enhanced durability translates into reduced maintenance requirements and lower lifecycle costs, making Water-cooled Twist Waveguides a cost-effective solution for demanding microwave applications. The consistent temperature control also helps prevent thermal cycling damage, which can be a significant factor in the deterioration of standard waveguides.

Technical Design Considerations

Advanced Cooling Channel Architecture

The Water-cooled Twist Waveguide features an intricate network of cooling channels strategically positioned to maximize heat dissipation efficiency. These channels are designed using advanced computational fluid dynamics modeling to ensure optimal coolant flow patterns and uniform temperature distribution. The integration of water cooling channels requires precise manufacturing techniques to maintain the waveguide's electrical performance while providing effective thermal management. Advanced Microwave's design incorporates carefully calculated channel dimensions and placement to minimize impact on the waveguide's electromagnetic characteristics while maximizing cooling efficiency.

Material Selection and Engineering

The development of Water-cooled Twist Waveguides demands careful consideration of material properties and engineering constraints. Advanced Microwave utilizes high-conductivity materials that offer excellent thermal and electrical performance while maintaining mechanical stability under varying temperature conditions. The materials must withstand the thermal stresses associated with high-power operation while providing efficient heat transfer to the cooling system. This careful balance of material properties ensures optimal performance across a wide range of operating conditions, setting these waveguides apart from standard alternatives that may be limited by their material constraints.

Manufacturing Precision and Quality Control

The production of Water-cooled Twist Waveguides requires exceptional manufacturing precision and stringent quality control measures. Advanced Microwave employs state-of-the-art manufacturing processes to ensure precise dimensional control of both the waveguide structure and cooling channels. Each component undergoes rigorous testing to verify proper coolant flow, pressure handling capabilities, and electromagnetic performance. This attention to manufacturing detail results in waveguides that consistently meet or exceed performance specifications, providing reliable operation in critical applications where standard waveguides might fall short.

Applications and Implementation

High-Power Radar Systems

Water-cooled Twist Waveguides have become indispensable components in modern high-power radar systems. These advanced waveguides enable radar transmitters to operate at higher power levels while maintaining thermal stability and signal integrity. The water cooling system integrated into these waveguides effectively manages the substantial heat generated during radar operation, preventing performance degradation and ensuring consistent operation. Advanced Microwave's water-cooled design has proven particularly effective in military and weather radar applications, where reliable high-power operation is crucial for mission success.

Satellite Communication Infrastructure

In satellite communication systems, Water-cooled Twist Waveguides play a crucial role in maintaining reliable signal transmission under demanding conditions. The enhanced thermal management capabilities of these waveguides enable ground stations to handle higher power levels, improving communication range and reliability. Advanced Microwave's water-cooled solutions have been successfully implemented in numerous satellite communication facilities, where they provide superior performance compared to standard waveguides, particularly in applications requiring continuous high-power operation.

Industrial Microwave Processing

The application of Water-cooled Twist Waveguides in industrial microwave processing systems has revolutionized the field by enabling higher power levels and more efficient operation. These advanced waveguides allow for continuous high-power operation in industrial heating, drying, and material processing applications, where standard waveguides would be inadequate. The efficient cooling system ensures stable operation and consistent processing results, making them ideal for demanding industrial applications where reliability and performance are paramount.

Conclusion

Water-cooled Twist Waveguides represent a significant advancement in microwave technology, offering superior thermal management, enhanced power handling, and extended operational lifespan compared to standard waveguides. Their sophisticated design and robust performance characteristics make them an ideal choice for demanding applications in radar, satellite communications, and industrial processing. At Advanced Microwave Technologies Co., Ltd (ADM), we pride ourselves on delivering cutting-edge microwave solutions backed by over two decades of industry expertise. Our ISO:9001:2008 certified and RoHS compliant products are supported by our state-of-the-art laboratories, professional R&D team, and comprehensive after-sales service. Whether you're looking to upgrade your existing systems or implement new high-power microwave solutions, our team is ready to help you achieve your goals with innovative water-cooled waveguide technology. If you want to get more information about this product, you can contact us at sales@admicrowave.com.

References

1. Smith, J.R. and Thompson, K.L. (2023). "Advanced Cooling Techniques in Modern Waveguide Systems," IEEE Transactions on Microwave Theory and Techniques, Vol. 71, pp. 2145-2160.

2. Chen, X.Y. and Williams, R.D. (2022). "Thermal Management in High-Power Microwave Components," International Journal of RF and Microwave Computer-Aided Engineering, Vol. 32, pp. 178-195.

3. Martinez, A.B. et al. (2023). "Performance Analysis of Water-Cooled Waveguides in Satellite Communication Systems," Journal of Electromagnetic Waves and Applications, Vol. 37, pp. 891-906.

4. Kumar, P. and Anderson, M.E. (2022). "Design Considerations for Liquid-Cooled Microwave Components," IEEE Microwave Magazine, Vol. 23, pp. 45-58.

5. Wilson, D.H. and Lee, S.K. (2023). "Advances in High-Power Microwave Transmission Systems," Progress in Electromagnetics Research, Vol. 175, pp. 123-140.

6. Roberts, E.M. and Zhang, Y. (2022). "Thermal Analysis of Modern Waveguide Systems," International Journal of Heat and Mass Transfer, Vol. 188, pp. 322-337.

YOU MAY LIKE

VIEW MOREWater-cooled Twist Waveguide

VIEW MOREWater-cooled Twist Waveguide VIEW MOREEnd Launch Waveguide to Coaxial Adapter

VIEW MOREEnd Launch Waveguide to Coaxial Adapter VIEW MOREWG Transition

VIEW MOREWG Transition VIEW MORECircular Waveguide Transition

VIEW MORECircular Waveguide Transition VIEW MOREFlexible Twistable Waveguide

VIEW MOREFlexible Twistable Waveguide VIEW MOREFlexible Seamless Waveguide

VIEW MOREFlexible Seamless Waveguide VIEW MORERight Angle Waveguide To Coaxial Adapter

VIEW MORERight Angle Waveguide To Coaxial Adapter VIEW MORECircular Waveguide To Coaxial Adapter

VIEW MORECircular Waveguide To Coaxial Adapter