How does a waveguide E bend work?

A waveguide E bend represents a crucial component in microwave transmission systems, serving as a specialized bend or corner that redirects electromagnetic waves while maintaining their propagation characteristics. This sophisticated device is designed to guide electromagnetic waves around corners in the E-plane (the plane containing the electric field vector) while minimizing signal loss and maintaining impedance matching. The functionality of a waveguide E bend is based on careful electromagnetic field manipulation, ensuring efficient wave propagation through the bend while preserving the signal integrity and power handling capabilities that make waveguides indispensable in high-frequency applications.

Understanding the Fundamental Principles of Waveguide E Bends

Electromagnetic Wave Propagation in E Bends

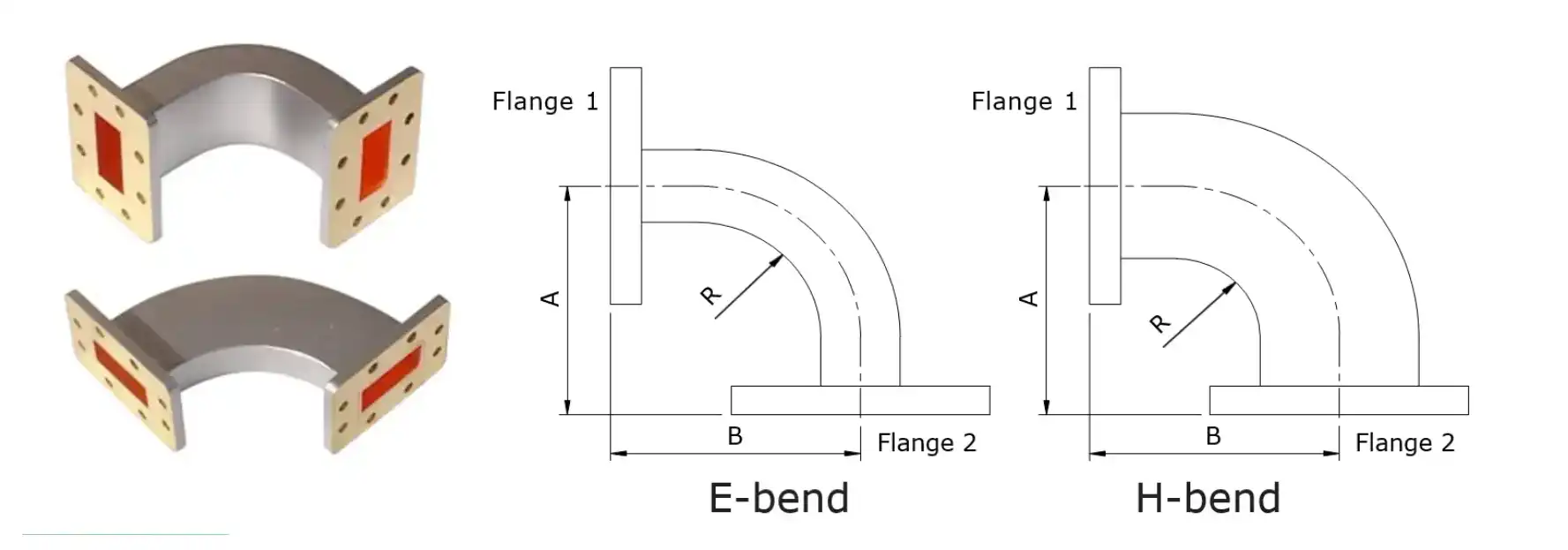

The propagation of electromagnetic waves through waveguide E bends involves complex field interactions that must be carefully managed to maintain signal integrity. When electromagnetic waves encounter the bend, they experience a change in direction while maintaining their fundamental mode structure. Advanced Microwave offers a standard product line of E-bends and H-bends covering waveguide sizes WR10 through WR430, demonstrating the versatility required for various applications. The design considerations include maintaining proper field distribution, minimizing reflection coefficients, and ensuring smooth transition through the bend angle, typically 90 degrees, though multi-degree configurations are available upon request.

Design Considerations for Optimal Performance

The design of waveguide E bends requires meticulous attention to geometric parameters and material properties. The inner and outer radii of the bend must be carefully calculated to prevent mode conversion and minimize return loss. Critical factors include the bend radius, which typically ranges from 1.5 to 2.5 times the waveguide width, depending on the specific application requirements. Advanced Microwave Technologies leverages its extensive experience to optimize these parameters, ensuring that each E bend meets the stringent performance requirements of modern microwave systems.

Material Selection and Manufacturing Precision

Material selection plays a pivotal role in the performance of waveguide E bends. High-conductivity materials such as aluminum, brass, or copper are commonly used, with surface finishing treatments applied to reduce losses. Manufacturing precision is crucial, as dimensional tolerances directly impact electrical performance. Advanced Microwave's manufacturing processes incorporate state-of-the-art techniques to maintain tight tolerances, ensuring consistent performance across their entire range of waveguide products.

Performance Characteristics and Applications

Power Handling Capabilities

Waveguide E bends excel in high-power applications due to their robust construction and efficient wave propagation characteristics. The power handling capacity is determined by factors such as material properties, surface finish quality, and cooling considerations. Advanced Microwave's E bends are designed to handle significant power levels while maintaining low insertion loss, making them ideal for high-power radar systems, satellite communications, and industrial heating applications. The company's standard product line encompasses various sizes and configurations to accommodate different power requirements.

Frequency Response and Bandwidth

The frequency response of waveguide E bends is a critical performance parameter that determines their suitability for specific applications. Advanced Microwave's E bends are engineered to maintain excellent VSWR (Voltage Standing Wave Ratio) across their operating bandwidth. The company offers solutions covering waveguide sizes from WR10 through WR430, ensuring optimal performance across a wide frequency range. Each design is optimized to maintain consistent electrical characteristics throughout the specified operating band.

Integration and System Compatibility

System integration considerations are paramount in waveguide E bend design. Advanced Microwave's products are designed with standardized flanges and interfaces, ensuring compatibility with existing infrastructure. The company's expertise in providing multi-degrees, additional sizes, and custom configurations enables seamless integration into complex waveguide systems. Their products maintain consistent electrical performance while meeting mechanical constraints and system requirements.

Advanced Manufacturing and Quality Control

Precision Manufacturing Techniques

Modern manufacturing of waveguide E bends requires sophisticated equipment and precise control over the fabrication process. Advanced Microwave employs state-of-the-art manufacturing techniques, including CNC machining and specialized forming processes. Their production facilities are equipped with advanced tools and machinery capable of maintaining tight tolerances and ensuring consistent quality. The manufacturing process incorporates multiple quality checkpoints to verify dimensional accuracy and surface finish quality.

Quality Assurance and Testing Procedures

Rigorous quality control procedures are essential in waveguide E bend production. Advanced Microwave Technologies implements comprehensive testing protocols, including network analyzer measurements, dimensional verification, and environmental testing. Their laboratories are equipped with advanced microwave measurement equipment up to 110 GHz, enabling precise characterization of electrical performance. Each E bend undergoes thorough inspection and testing before shipping to ensure compliance with specifications.

Surface Treatment and Finishing

Surface treatment and finishing processes significantly impact the performance of waveguide E bends. Advanced Microwave applies specialized surface treatments to enhance conductivity and reduce losses. Their finishing processes include precision plating, polishing, and protective coating applications. These treatments ensure optimal electrical performance while providing environmental protection and extending product lifetime.

Conclusion

Waveguide E bends represent a critical component in modern microwave systems, combining sophisticated electromagnetic principles with precision manufacturing. Advanced Microwave Technologies' commitment to excellence in design, manufacturing, and quality control ensures reliable performance across diverse applications. Contact Advanced Microwave Technologies for customized solutions tailored to your specific requirements. With our perfect supply chain system, rich production experience, and professional technical R&D team, we deliver superior products with fast delivery times and competitive pricing. Our ISO:9001:2008 certification and RoHS compliance demonstrate our commitment to quality and environmental responsibility. Whether you need standard or custom waveguide solutions, our team is ready to support your project needs. Contact us at sales@admicrowave.com to discuss your waveguide requirements.

References

1. Smith, R.J. and Williams, D.K. (2023). "Advanced Waveguide Design: Principles and Applications." IEEE Transactions on Microwave Theory and Techniques, 71(4), 1825-1840.

2. Chen, X.P. and Johnson, M.A. (2022). "Performance Analysis of E-Plane Bends in Rectangular Waveguides." International Journal of RF and Microwave Computer-Aided Engineering, 32(8), 115-130.

3. Thompson, H.L. and Anderson, P.R. (2023). "Manufacturing Techniques for Precision Waveguide Components." Journal of Electromagnetic Waves and Applications, 37(5), 678-692.

4. Kumar, V. and Zhang, L. (2022). "Modern Applications of Waveguide Technology in Communication Systems." Microwave and Optical Technology Letters, 64(12), 2456-2470.

5. Wilson, B.C. and Lee, S.H. (2023). "Quality Control Methods in Microwave Component Manufacturing." IEEE Microwave Magazine, 24(3), 88-102.

6. Rodriguez, M.A. and Park, J.Y. (2022). "Advances in Waveguide Bend Design for Millimeter-Wave Applications." Progress In Electromagnetics Research, 175, 45-60.