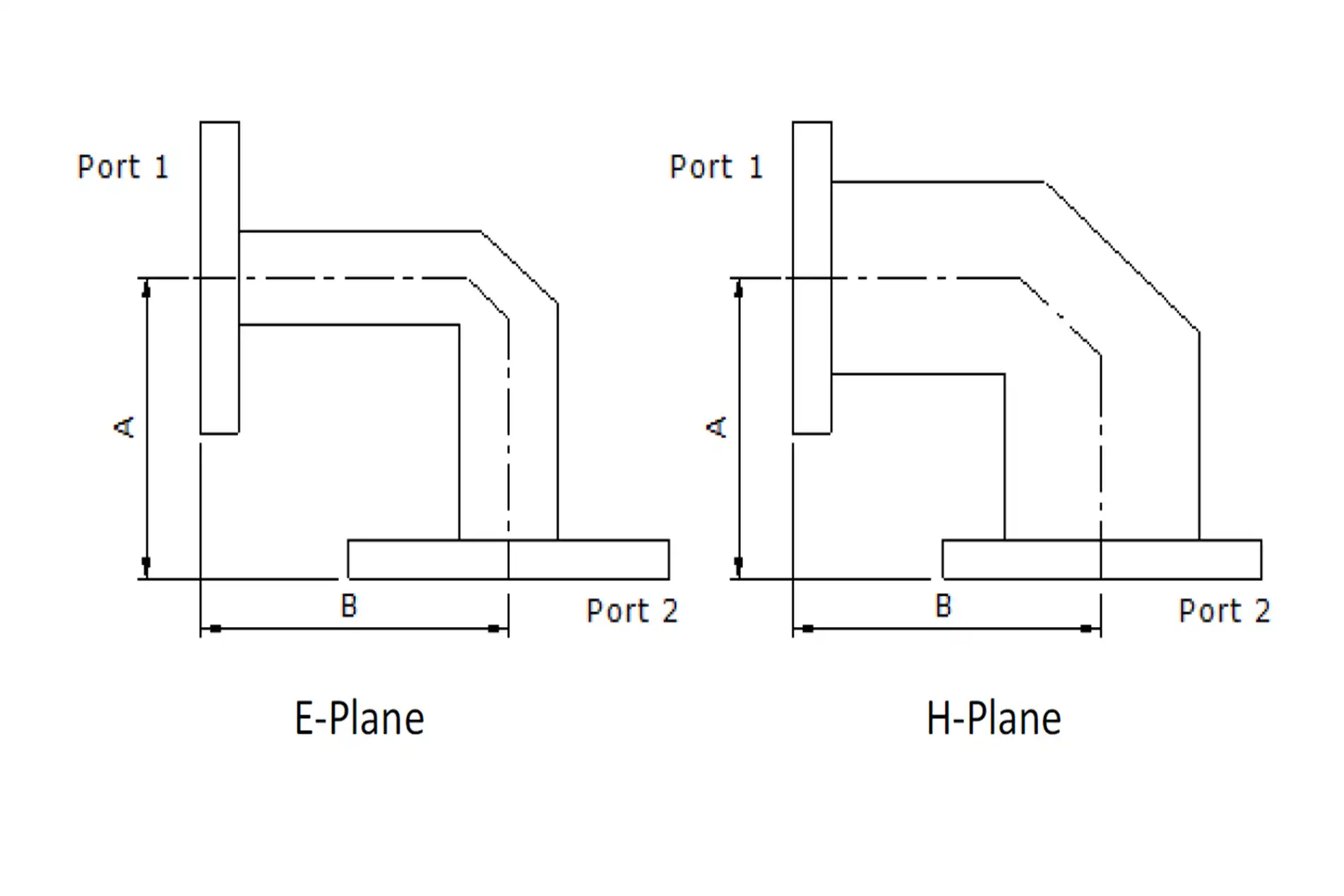

Waveguide Miter Bend

Waveguide Miter Bend Introduction

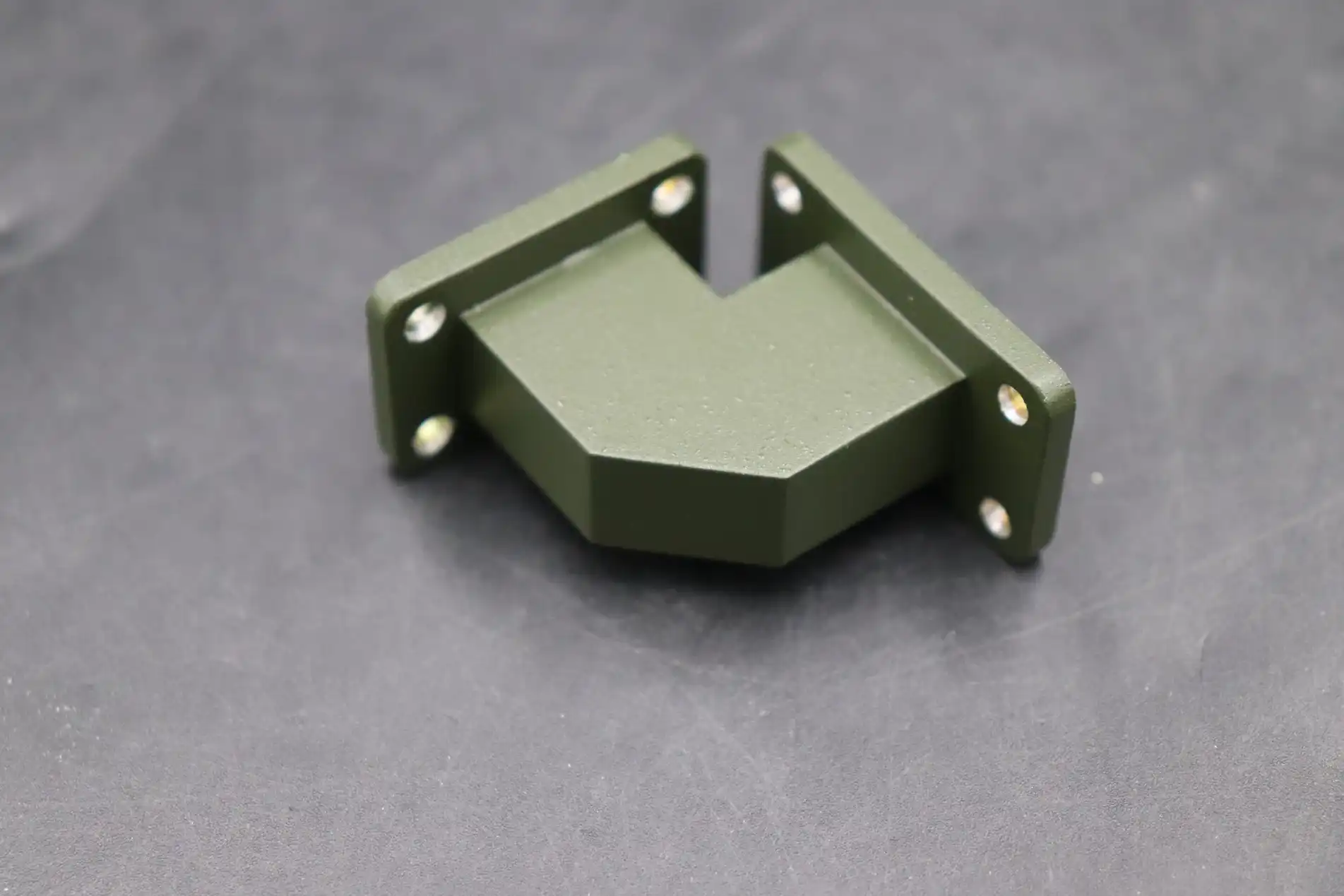

Waveguide Miter Bend are essential components for routing microwave signals in a variety of systems, including satellite communication, radar, and aerospace applications. These bends allow for efficient redirection of waveguides without compromising signal integrity, making them indispensable for modern high-frequency operations.

At Advanced Microwave Technologies Co., Ltd, we specialize in manufacturing top-quality products designed to meet the rigorous demands of our B2B partners across industries. With over 30 years of expertise and cutting-edge facilities, we deliver products that combine performance, reliability, and compliance.

Product Specifications

| Feature | Details |

|---|---|

| Frequency Range | Up to 110 GHz |

| Waveguide Sizes | WR10 to WR2300 |

| Material | Aluminum, Copper, Brass, or customized alloys |

| Bend Angle | 90° (standard), customizable to other angles |

| Finish | RoHS-compliant plating, including silver and gold finishes |

| VSWR (Voltage Standing Wave Ratio) | ≤ 1.05 |

| Operating Temperature | -40°C to +85°C |

| Compliance | ISO 9001:2008 certified, RoHS compliant |

Waveguide Miter Bend Benefits

- Signal Integrity: Waveguide Miter Bend ensures minimal signal loss and optimal performance, even in high-frequency environments.

- Durability: Built with high-grade materials that resist corrosion and wear.

- Customizable: Tailored designs for specific requirements, including non-standard waveguide sizes or angles.

- Cost-Effective: Provides long-term reliability, reducing maintenance costs.

Technical Features

- Precision Engineering: Advanced manufacturing techniques ensure tight tolerances for perfect alignment and minimal VSWR.

- Versatility: Compatible with various waveguide systems and frequency bands.

- Lightweight Design: Suitable for weight-sensitive applications like aerospace systems.

- Thermal Stability: Reliable operation across a wide temperature range.

Waveguide Miter Bend Applications

Waveguide Miter Bends are used in:

- Satellite Communication: They are used for efficient signal routing in satellite transponders and antennas, ensuring reliable communication in space.

- Radar Systems: Miter bends enable the precise redirection of high-frequency waves, crucial for accurate detection and imaging in radar applications.

- Aerospace: These components offer lightweight, durable solutions for navigation systems, optimizing performance in critical aerospace environments.

- Telecommunications: Miter bends are integral to the setup of base stations and relay systems, facilitating smooth signal transmission.

- Defense: In advanced weapon systems, miter bends manage precision signal routing for enhanced system accuracy and reliability.

OEM Services

At Advanced Microwave Technologies, we understand that every application has unique needs. That's why we offer:

- Custom Designs: We work closely with clients to adjust dimensions, materials, and finishes to meet specific needs, ensuring the highest performance.

- Prototyping: We develop and test prototypes to verify the design, ensuring that the final product performs optimally.

- Global Delivery: Our efficient logistics network ensures reliable delivery to support your supply chain needs, no matter where you are.

- Technical Support: We provide expert guidance for installation, impedance matching, and troubleshooting to ensure smooth operation and maximum performance throughout the lifecycle.

FAQ

1. What are the key advantages of using a Waveguide Miter Bend?

Miter bends allow for efficient routing of signals with minimal insertion loss. They are designed to maintain high performance at various frequencies, offering low power loss and high transmission efficiency even in complex systems.

2. What materials are typically used for they?

Miter bends are usually made from materials such as brass, aluminum, or copper, which offer excellent conductivity and durability. In some cases, stainless steel or other alloys may be used for more specialized environments.

3. How do I choose the right miter bend for my application?

Selection depends on factors like operating frequency, power handling, and physical size constraints. Consulting with an experienced supplier or manufacturer can help ensure the right choice for your specific needs.

4. Are they customizable?

Yes, many manufacturers offer customizable miter bends to meet specific dimensional, material, or performance requirements, making them versatile for a wide range of applications.

Contact Us

For more information about the Waveguide Miter Bend,please feel free to contact us at sales@admicrowave.com. Our team is ready to assit you!