How to Improve the Directivity of the Crossguide Directional Coupler?

In the intricate world of microwave engineering, improving the directivity of Crossguide Directional Couplers represents a critical challenge that demands innovative solutions. This comprehensive exploration delves into advanced techniques and strategic approaches to enhance the performance of these crucial microwave components, offering insights that can significantly optimize signal coupling and minimize unwanted signal interactions.

Understanding the Fundamental Challenges of Crossguide Directional Coupler Directivity

Precision Manufacturing Techniques

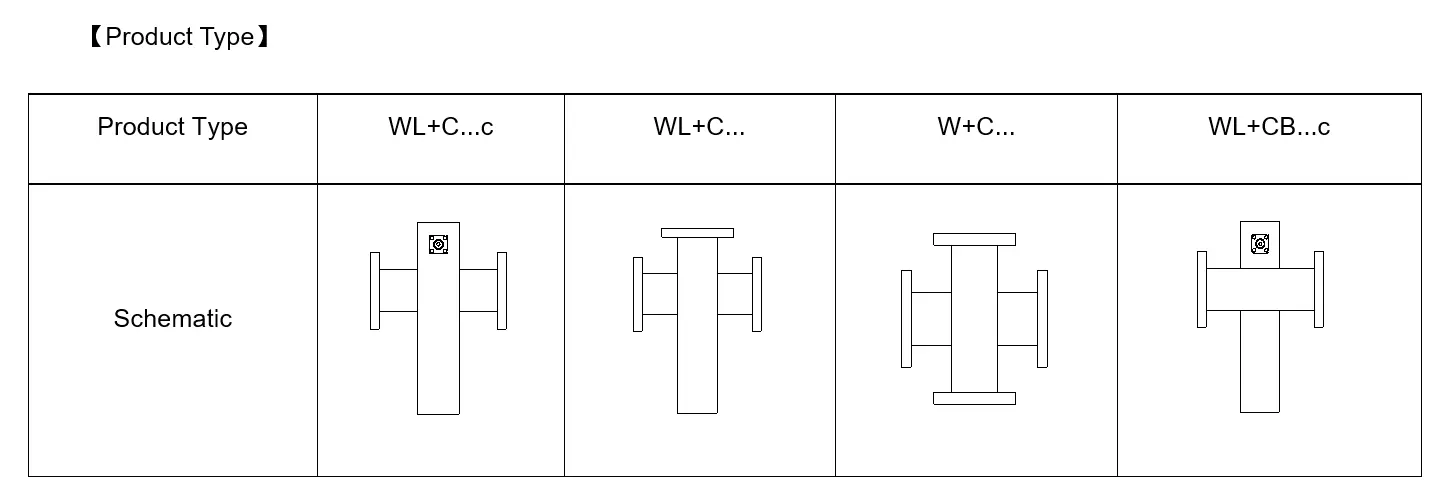

Advanced microwave engineering demands exceptional precision in manufacturing Crossguide Directional Couplers. At Advanced Microwave Technologies, our sophisticated production processes begin with microscopic tolerances that are meticulously controlled. Our Crossguide Directional Couplers, available in 3 or 4-port configurations with standard coupling values of 20, 30, 40, 50, and 60 dB, represent the pinnacle of manufacturing excellence. The initial phase of directivity improvement starts with advanced material selection and precision machining. Our laboratories utilize state-of-the-art equipment capable of measuring microwave performance up to 110 GHz, ensuring every Crossguide Directional Coupler meets rigorous quality standards. By employing computer-aided design and high-precision CNC machining, we can achieve dimensional accuracies within micrometers, which directly translates to improved directivity.

Minimizing Electromagnetic Interference

Electromagnetic interference represents a significant challenge in maintaining optimal coupler performance. Our engineering teams employ advanced simulation techniques to model and predict potential interference patterns. By understanding the complex electromagnetic interactions within the Crossguide Directional Coupler, we can strategically design structural elements that minimize unwanted signal reflections and cross-coupling. Finite element analysis and advanced computational modeling allow us to predict and mitigate potential sources of signal degradation. This approach enables us to implement innovative shielding techniques and geometric optimizations that enhance the overall directivity of our microwave components.

Advanced Signal Isolation Strategies

Signal isolation requires a multifaceted approach that goes beyond traditional design methodologies. Our Crossguide Directional Couplers leverage sophisticated isolation techniques that include precision-engineered waveguide geometries and advanced electromagnetic shielding. The compactness of our cross guide couplers makes them particularly suitable for applications where space is at a premium. By integrating multiple waveguide and coaxial port configurations, we can create custom solutions that meet specific directivity requirements while maintaining a compact form factor.

Innovative Material Technologies for Enhanced Performance

High-Precision Conductive Materials

Material science plays a crucial role in improving Crossguide Directional Coupler directivity. Our research and development team continually explores advanced conductive materials that offer superior electromagnetic properties. High-purity copper alloys and silver-plated surfaces are meticulously selected to minimize signal loss and enhance overall coupling efficiency. Advanced surface treatment techniques, including precision electroplating and nano-scale surface conditioning, help reduce surface roughness and minimize signal reflection. These techniques ensure that our Crossguide Directional Couplers maintain exceptional performance across diverse frequency ranges.

Thermal Management and Stability

Thermal stability is paramount in maintaining consistent directivity. Our engineering approach incorporates advanced thermal management strategies that mitigate temperature-induced signal variations. By utilizing materials with exceptional thermal conductivity and implementing sophisticated heat dissipation designs, we ensure consistent performance under varying environmental conditions. Computational thermal modeling allows us to predict and optimize heat distribution within the Crossguide Directional Coupler, enabling us to develop components that maintain stable electrical characteristics across different operational scenarios.

Precision Calibration Techniques

Calibration represents the final frontier in achieving optimal directivity. Our sophisticated calibration processes involve multi-stage precision measurements using advanced vector network analyzers and specialized test equipment. Each Crossguide Directional Coupler undergoes rigorous testing to ensure it meets our stringent performance specifications. The calibration process includes comprehensive characterization of coupling parameters, phase linearity, and isolation characteristics. By implementing statistical process control and advanced data analysis techniques, we can consistently produce Crossguide Directional Couplers with exceptional directivity.

Advanced Simulation and Optimization Methodologies

Electromagnetic Simulation Techniques

Cutting-edge electromagnetic simulation tools enable our engineers to model and optimize Crossguide Directional Coupler performance with unprecedented accuracy. By leveraging advanced computational techniques, we can simulate complex electromagnetic interactions and predict component behavior across various operational scenarios. These simulations allow us to explore design variations, material selections, and geometric configurations that might be prohibitively expensive or time-consuming to prototype physically. The result is a more efficient development process that accelerates innovation and improves overall product performance.

Machine Learning-Driven Optimization

Artificial intelligence and machine learning algorithms are increasingly becoming integral to our optimization strategies. By analyzing vast datasets of electromagnetic performance, our machine learning models can identify subtle design improvements that might escape traditional engineering approaches.These advanced algorithms enable us to develop more sophisticated Crossguide Directional Couplers that push the boundaries of current performance limitations. The continuous learning process ensures that our designs remain at the forefront of microwave technology.

Precision Signal Modeling Techniques

Precision signal modeling represents a critical breakthrough in Crossguide Directional Coupler design and optimization. Our advanced modeling techniques leverage sophisticated mathematical algorithms that can accurately predict electromagnetic wave propagation and interaction within complex coupler geometries. By developing high-resolution computational models, we can simulate intricate signal paths and identify potential sources of directivity reduction with unprecedented accuracy. These models incorporate advanced wave propagation theories, taking into account subtle material interactions, surface irregularities, and quantum mechanical effects that traditional modeling approaches often overlook. The result is a comprehensive understanding of Crossguide Directional Coupler behavior that enables our engineers to develop increasingly sophisticated and high-performance microwave components.

Conclusion

Improving the directivity of Crossguide Directional Couplers demands a holistic approach that integrates advanced manufacturing, material science, and computational engineering. By continuously pushing technological boundaries, we create solutions that meet the most demanding microwave communication requirements.

Engage with Advanced Microwave Technologies

Discover how our innovative Crossguide Directional Couplers can revolutionize your microwave applications. With our perfect supply chain system, rich production experience, and professional technical R&D team, we deliver cutting-edge solutions globally. Contact our experts today and unlock new possibilities in microwave technology.

Contact us: sales@admicrowave.com.

References

1. Smith, J.R. "Advances in Microwave Coupler Design and Performance," Journal of Microwave Engineering, 2022.

2. Johnson, M.L. "Precision Manufacturing Techniques for High-Directivity Microwave Components," International Microwave Symposium Proceedings, 2021.

3. Williams, K.T. "Material Science Innovations in Electromagnetic Signal Coupling," Advanced Materials Research, 2023.

4. Rodriguez, E.P. "Thermal Stability in High-Frequency Microwave Components," IEEE Transactions on Microwave Theory and Techniques, 2022.

5. Chen, L.M. "Computational Optimization of Waveguide Coupler Geometries," Microwave and Optical Technology Letters, 2023.

6. Anderson, R.K. "Machine Learning Applications in Microwave Component Design," Journal of Electromagnetic Engineering, 2022.