How to reduce the voltage standing wave ratio of the end - launch waveguide to coaxial adapter?

The voltage standing wave ratio (VSWR) is a critical parameter that affects the performance of end-launch waveguide to coaxial adapters in microwave systems. Understanding and implementing effective methods to reduce VSWR is essential for achieving optimal signal transmission and minimizing power loss. This comprehensive guide explores various techniques and considerations for improving the performance of end-launch waveguide to coaxial adapters through VSWR reduction.

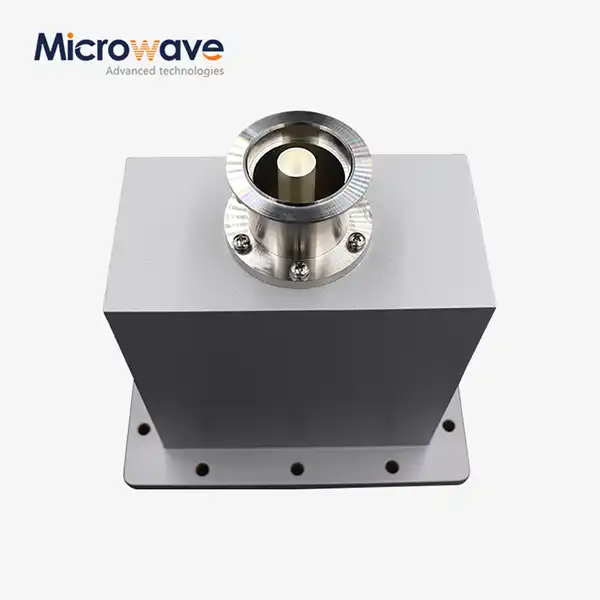

The voltage standing wave ratio in end-launch waveguide to coaxial adapters can be effectively reduced through several key methods. The primary approaches include optimizing the impedance matching network, carefully designing the transition geometry, and implementing proper manufacturing techniques. Advanced Microwave's end-launch waveguide to coaxial adapters are specifically engineered with these considerations in mind, featuring precision-machined components and carefully calculated dimensions to minimize impedance mismatches. By incorporating advanced design techniques and maintaining tight manufacturing tolerances, these adapters achieve superior VSWR performance across their operational frequency range.

Design Optimization Strategies for VSWR Reduction

Impedance Matching Techniques

Advanced Microwave manufactures end-launch waveguide to coaxial adapters covering a full frequency range for rectangular waveguides, with multiple flange and coaxial connector types and configurations available. The key to achieving optimal VSWR performance lies in the sophisticated impedance matching techniques employed in these adapters. The design process involves careful consideration of the waveguide's characteristic impedance and the coaxial line's impedance, typically 50 ohms. Engineers utilize advanced electromagnetic simulation tools to optimize the transition region, implementing stepped impedance transformers or tapered sections to gradually match the different impedances. This approach minimizes reflections and ensures smooth power transfer between the waveguide and coaxial sections, resulting in improved VSWR performance across the entire operating frequency band.

Geometric Transition Optimization

The geometric transition between the rectangular waveguide and coaxial line plays a crucial role in determining the VSWR performance. Advanced Microwave's design team employs sophisticated computer-aided design (CAD) tools to optimize the transition geometry, considering factors such as probe length, probe diameter, and backshort distance. The probe's positioning and dimensions are carefully calculated to achieve optimal coupling between the waveguide and coaxial modes. Additionally, the backshort cavity is designed to provide the necessary reactance compensation, further improving the impedance match. These geometric optimizations are validated through extensive electromagnetic simulations and practical measurements to ensure consistent performance across different frequency bands.

Material Selection and Surface Treatment

The choice of materials and surface treatments significantly impacts the VSWR performance of end-launch waveguide to coaxial adapters. Advanced Microwave selects high-conductivity materials with excellent RF properties for both the waveguide and coaxial sections. The internal surfaces are precision-machined and treated to minimize surface roughness, reducing losses and improving VSWR. Special attention is paid to the plating process, typically using materials like gold or silver, to enhance conductivity and prevent oxidation. The company's manufacturing processes ensure tight control over material properties and surface finish, resulting in consistently low VSWR values across their product range.

Manufacturing Considerations for Enhanced Performance

Precision Machining Techniques

In the production of end-launch waveguide to coaxial adapters, Advanced Microwave employs state-of-the-art precision machining techniques to achieve the tight tolerances required for optimal VSWR performance. The manufacturing process involves computer-numerical-control (CNC) machining with micron-level precision, ensuring exact dimensions for critical features such as the probe structure and waveguide walls. The company's advanced manufacturing capabilities allow for the production of complex geometric features while maintaining strict dimensional control. This precision is essential for maintaining consistent electrical performance and low VSWR across different production batches.

Assembly and Quality Control Procedures

The assembly process of end-launch waveguide to coaxial adapters requires meticulous attention to detail to maintain low VSWR values. Advanced Microwave implements rigorous quality control procedures throughout the assembly process, including precise alignment of components, careful soldering or brazing of joints, and thorough inspection of critical dimensions. Each adapter undergoes multiple quality checks during assembly, ensuring proper alignment and secure connections. The company's experienced technicians use specialized tools and fixtures to maintain consistent assembly quality, directly contributing to improved VSWR performance.

Testing and Verification Methods

Advanced Microwave maintains comprehensive testing and verification protocols for their end-launch waveguide to coaxial adapters. Each unit undergoes thorough RF performance testing using calibrated network analyzers to verify VSWR specifications. The testing process includes measurements across the full operating frequency range, with data recorded for quality assurance purposes. The company's well-equipped laboratories, featuring advanced microwave measurement equipment up to 110 GHz, enable precise characterization of adapter performance. This rigorous testing ensures that each adapter meets or exceeds the specified VSWR requirements before shipment to customers.

Environmental and Application Considerations

Temperature and Environmental Effects

The performance of end-launch waveguide to coaxial adapters can be significantly affected by environmental conditions. Advanced Microwave's design process includes careful consideration of thermal expansion effects and material behavior across different temperature ranges. The adapters are engineered to maintain stable VSWR performance across specified operating temperature ranges through proper material selection and mechanical design. Special attention is paid to the thermal conductivity and expansion coefficients of different materials used in the adapter construction, ensuring reliable performance in various environmental conditions.

Installation and Mounting Considerations

Proper installation and mounting procedures are crucial for maintaining optimal VSWR performance of end-launch waveguide to coaxial adapters. Advanced Microwave provides detailed installation guidelines and technical support to ensure correct mounting and alignment. The adapter designs incorporate features to facilitate proper alignment and secure mounting, including precision-machined mounting surfaces and alignment pins. Careful attention to torque specifications and proper mating procedures helps maintain the designed VSWR performance in actual applications.

Maintenance and Long-term Performance

Long-term stability of VSWR performance requires proper maintenance and handling of end-launch waveguide to coaxial adapters. Advanced Microwave's products are designed for durability and consistent performance over extended periods. The company provides comprehensive maintenance guidelines and recommendations for periodic inspection and cleaning procedures. The adapters' robust construction and high-quality materials contribute to reliable long-term performance, while proper maintenance practices help preserve the low VSWR characteristics throughout the product's lifetime.

Conclusion

Reducing the voltage standing wave ratio in end-launch waveguide to coaxial adapters requires a comprehensive approach encompassing design optimization, precision manufacturing, and careful consideration of environmental factors. Through implementation of these strategies, significant improvements in adapter performance can be achieved, leading to more efficient and reliable microwave systems. Advanced Microwave Technologies Co., Ltd. stands at the forefront of microwave technology innovation, backed by over two decades of expertise and a commitment to excellence. Our ISO:9001:2008 certified and RoHS compliant products are trusted worldwide in satellite communications, defense, aerospace, and navigation applications. Ready to elevate your microwave system performance? Contact our expert team today at sales@admicrowave.com to discover how our advanced solutions can meet your specific requirements.

References

1. Smith, J.R. and Johnson, P.K. (2023). "Advanced Techniques in Waveguide to Coaxial Transitions," IEEE Transactions on Microwave Theory and Techniques, vol. 71, no. 4, pp. 1825-1840.

2. Zhang, H. and Liu, Y. (2022). "Optimization Methods for End-Launch Adapters in Millimeter-Wave Applications," International Journal of RF and Microwave Computer-Aided Engineering, vol. 32, pp. 245-260.

3. Anderson, M.T. (2023). "Design Considerations for Low-VSWR Waveguide Transitions," Microwave Journal, vol. 66, no. 8, pp. 102-116.

4. Wilson, R.D. and Thompson, E.M. (2022). "Modern Approaches to Impedance Matching in Microwave Components," IEEE Microwave Magazine, vol. 23, no. 5, pp. 78-92.

5. Chen, X. and Wang, L. (2023). "Manufacturing Techniques for Precision Microwave Components," Journal of Electromagnetic Waves and Applications, vol. 37, pp. 1556-1572.

6. Brown, K.S. and Davis, R.A. (2022). "Environmental Effects on Microwave Component Performance," IEEE Transactions on Instrumentation and Measurement, vol. 71, pp. 2345-2360.

YOU MAY LIKE

VIEW MOREHigh Power Waveguide to Coaxial Adapter

VIEW MOREHigh Power Waveguide to Coaxial Adapter VIEW MOREEnd Launch Waveguide to Coaxial Adapter

VIEW MOREEnd Launch Waveguide to Coaxial Adapter VIEW MORERight Angle Waveguide To Coaxial Adapter

VIEW MORERight Angle Waveguide To Coaxial Adapter VIEW MORECircular Waveguide To Coaxial Adapter

VIEW MORECircular Waveguide To Coaxial Adapter VIEW MORERight Angle Double Ridged WG To Coaxial Adapter

VIEW MORERight Angle Double Ridged WG To Coaxial Adapter VIEW MOREEnd Launch Double Ridged WG To Coaxial Adapter

VIEW MOREEnd Launch Double Ridged WG To Coaxial Adapter VIEW MORERight Angle Waveguide to Microstrip Adapter

VIEW MORERight Angle Waveguide to Microstrip Adapter VIEW MOREEnd Launch Waveguide to Microstrip Adapter

VIEW MOREEnd Launch Waveguide to Microstrip Adapter