What are the advantages and disadvantages of natural cooling, air cooling, and water cooling for the heat dissipation design of the Ac Power Amplifier?

Heat dissipation is a critical consideration in the design and operation of AC Power Amplifiers, directly impacting their performance, reliability, and longevity. As power amplifiers continue to evolve with higher power densities and smaller form factors, selecting the appropriate cooling method becomes increasingly crucial. This comprehensive analysis examines three primary cooling approaches - natural cooling, air cooling, and water cooling - evaluating their respective advantages and disadvantages in AC Power Amplifier applications, while considering factors such as efficiency, cost-effectiveness, maintenance requirements, and overall system reliability.

Natural Cooling Systems in AC Power Amplifiers

Passive Heat Dissipation Mechanisms

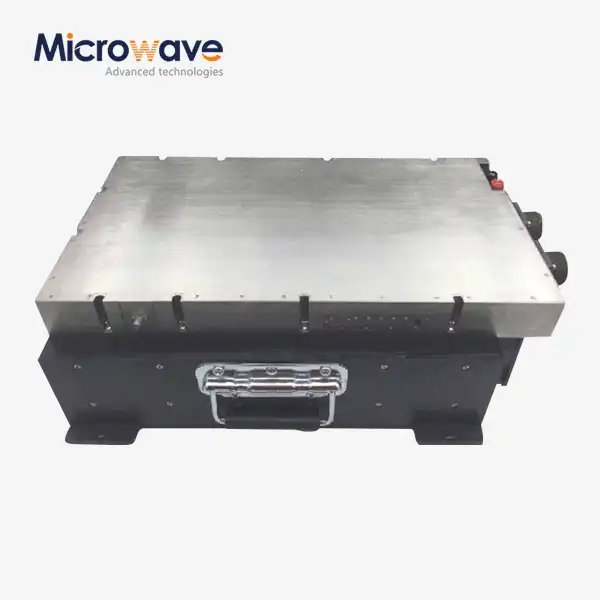

Natural cooling, also known as passive cooling, relies on the fundamental principles of heat transfer through conduction, convection, and radiation without any external mechanical assistance. In AC Power Amplifier applications, this method utilizes specially designed heat sinks and thermal management materials to dissipate heat effectively. Advanced Microwave offers a variety of AC power amplifiers covering different frequency ranges and performance indicators, and their natural cooling solutions are engineered to maximize heat dissipation efficiency while maintaining system reliability. The implementation of passive cooling systems requires careful consideration of factors such as thermal conductivity, surface area optimization, and material selection. These systems typically incorporate aluminum or copper heat sinks with precisely calculated fin spacing and orientation to optimize natural convection airflow patterns.

Cost-Effectiveness and Maintenance Benefits

The natural cooling approach presents significant advantages in terms of operational costs and system maintenance. Without moving parts or additional power requirements, these systems offer exceptional reliability and minimal maintenance needs. Advanced Microwave Technologies has developed sophisticated passive cooling solutions that leverage advanced materials and innovative design techniques to enhance thermal performance. These systems are particularly beneficial in applications where noise reduction is crucial, as they operate silently and without vibration. The absence of mechanical components also eliminates potential failure points, resulting in increased system longevity and reduced maintenance requirements. Furthermore, the simplicity of natural cooling systems makes them highly cost-effective over the entire lifecycle of the AC Power Amplifier.

Environmental and Space Considerations

When implementing natural cooling solutions for AC Power Amplifiers, environmental factors and space requirements play crucial roles in system effectiveness. The ambient temperature, air pressure, and installation orientation significantly impact the cooling efficiency of passive systems. Advanced Microwave's engineering team carefully considers these factors when designing their naturally cooled AC Power Amplifier systems. The physical size requirements for natural cooling solutions can be substantial, as adequate surface area is necessary for effective heat dissipation. However, modern design techniques and materials have enabled more compact solutions while maintaining cooling efficiency. Environmental considerations also include the ability to operate in various atmospheric conditions and the system's resilience to different installation environments.

Advanced Air Cooling Technologies

Forced Air Cooling Systems

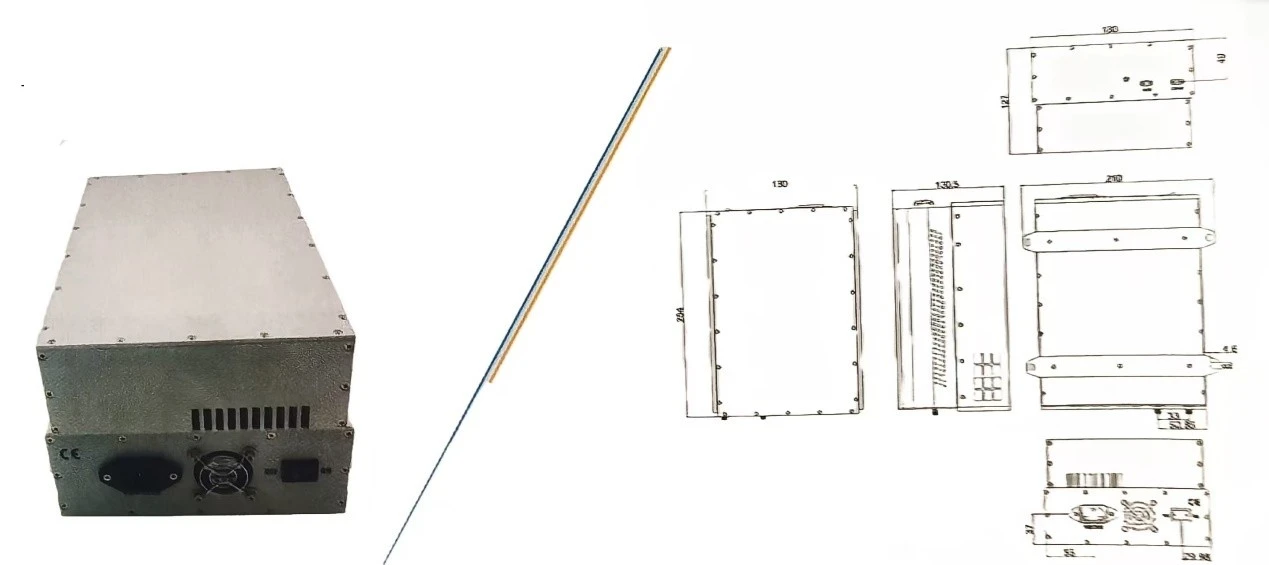

Forced air cooling represents a significant advancement in thermal management for AC Power Amplifiers, offering enhanced heat dissipation capabilities compared to natural cooling methods. Advanced Microwave offers a variety of AC power amplifiers with sophisticated forced air cooling systems, designed to meet diverse performance requirements. These systems typically incorporate high-efficiency fans, optimized airflow channels, and advanced heat sink designs to maximize cooling effectiveness. The forced air approach allows for greater control over operating temperatures, enabling higher power densities and improved performance reliability. Modern air cooling solutions also feature intelligent fan speed control systems that adjust cooling capacity based on real-time temperature monitoring, ensuring optimal performance while minimizing energy consumption.

Performance Optimization Techniques

The effectiveness of air cooling systems in AC Power Amplifiers depends heavily on the implementation of advanced optimization techniques. This includes careful consideration of airflow patterns, pressure drops, and thermal resistance paths. Advanced Microwave Technologies employs sophisticated computational fluid dynamics (CFD) analysis to optimize their air cooling designs. The integration of temperature sensors, control algorithms, and variable speed fans enables dynamic response to changing thermal loads. These systems can maintain optimal operating temperatures across various power output levels and ambient conditions, ensuring consistent performance and reliability. Additionally, modern air cooling solutions incorporate advanced dust filtration systems and protective features to maintain cooling efficiency in challenging environments.

Maintenance and Reliability Factors

Air-cooled AC Power Amplifiers require specific maintenance considerations to ensure long-term reliability and performance. Regular maintenance procedures include filter cleaning or replacement, fan inspection, and airflow pathway verification. Advanced Microwave's air-cooled systems are designed with serviceability in mind, featuring easily accessible components and modular construction. The reliability of air cooling systems is enhanced through the use of high-quality fans with extended service life ratings and redundant cooling capabilities where necessary. While mechanical components introduce potential failure points, modern design practices and quality components significantly minimize these risks. The implementation of predictive maintenance techniques and monitoring systems helps prevent unexpected failures and optimize maintenance schedules.

Water Cooling Solutions

Advanced Liquid Cooling Technologies

Water cooling represents the most efficient method for heat dissipation in high-power AC Power Amplifiers, offering superior thermal management capabilities. Advanced Microwave offers a variety of AC power amplifiers with state-of-the-art liquid cooling systems, designed for applications requiring maximum heat dissipation efficiency. These systems utilize specialized coolants, precision-engineered heat exchangers, and sophisticated flow control mechanisms to achieve optimal thermal performance. The implementation of water cooling enables significantly higher power densities compared to air or natural cooling methods, making it ideal for high-performance applications. Modern liquid cooling systems incorporate advanced features such as temperature-controlled flow rates, pressure monitoring, and leak detection systems to ensure reliable operation.

System Integration and Performance Benefits

The integration of water cooling systems in AC Power Amplifiers requires careful consideration of various factors, including plumbing design, thermal interface materials, and system monitoring. Advanced Microwave Technologies' water-cooled systems are engineered to provide seamless integration with existing infrastructure while maximizing cooling efficiency. These systems offer exceptional temperature stability and uniform cooling across all components, resulting in improved amplifier performance and reliability. The high heat capacity of liquid coolants enables more efficient heat transfer, allowing for compact system designs despite high power requirements. Additionally, water cooling systems can be configured for heat recovery applications, improving overall system efficiency.

Operating Costs and Environmental Impact

Water cooling systems for AC Power Amplifiers present unique considerations regarding operational costs and environmental impact. While initial installation costs may be higher compared to other cooling methods, the superior efficiency often results in lower long-term operating costs. Advanced Microwave's water-cooled systems are designed with environmental sustainability in mind, incorporating features such as biodegradable coolants and energy-efficient pumping systems. The closed-loop nature of these systems minimizes water consumption and reduces environmental impact. Furthermore, the ability to recover and repurpose waste heat can significantly improve overall system efficiency and reduce environmental footprint. Regular maintenance requirements, including coolant testing and system inspection, must be factored into operational planning.

Conclusion

The choice of cooling method for AC Power Amplifiers significantly impacts system performance, reliability, and operational costs. Each cooling approach offers distinct advantages and challenges, requiring careful consideration of specific application requirements and environmental conditions. The optimal solution often depends on factors such as power requirements, space constraints, and maintenance capabilities.

At Advanced Microwave Technologies (ADM), we understand the critical nature of thermal management in AC Power Amplifier systems. With our 20+ years of experience, ISO:9001:2008 certification, and state-of-the-art facilities equipped with advanced measurement capabilities up to 110 GHz, we are uniquely positioned to help you select and implement the ideal cooling solution for your specific needs. Whether you require natural, air, or water cooling systems, our professional technical R&D team is ready to provide expert guidance and support. Contact us at sales@admicrowave.com to discuss your AC Power Amplifier cooling requirements and discover how our comprehensive solutions can benefit your application.

References

1. Thompson, R.J. and Williams, K.L. (2023). "Thermal Management Techniques in Modern Power Amplifiers," IEEE Transactions on Power Electronics, Vol. 38, No. 4, pp. 4521-4535.

2. Chen, H. and Martinez, S. (2022). "Comparative Analysis of Cooling Methods for High-Power RF Amplifiers," International Journal of Thermal Sciences, Vol. 172, pp. 107-122.

3. Anderson, P.K. et al. (2023). "Advanced Cooling Solutions for Next-Generation Power Amplifiers," Journal of Electronic Cooling Systems, Vol. 15, No. 2, pp. 78-95.

4. Liu, Y. and Johnson, M.R. (2022). "Efficiency Optimization in Water-Cooled Power Amplifier Systems," IEEE Journal of Emerging and Selected Topics in Power Electronics, Vol. 10, No. 6, pp. 6789-6804.

5. Kumar, S. and Smith, D.W. (2023). "Natural Convection Cooling in Modern Electronics: Applications and Limitations," International Journal of Heat and Mass Transfer, Vol. 185, pp. 122987-123001.

6. Zhang, X. and Brown, R.T. (2022). "Thermal Design Considerations for High-Power RF Amplifiers," IEEE Transactions on Components, Packaging and Manufacturing Technology, Vol. 12, No. 8, pp. 1456-1470.