What are the Differences Between Various Types of WG Termination Connectors?

In the intricate world of microwave communication technologies, waveguide (WG) termination connectors play a critical role in signal management and system performance. Understanding the nuanced differences between various types of WG Termination connectors is essential for engineers, researchers, and professionals working in satellite communications, defense, aerospace, and telecommunications industries. This comprehensive guide delves deep into the complexities of WG Termination connectors, exploring their diverse characteristics, applications, and technological innovations that set them apart in the modern communication landscape.

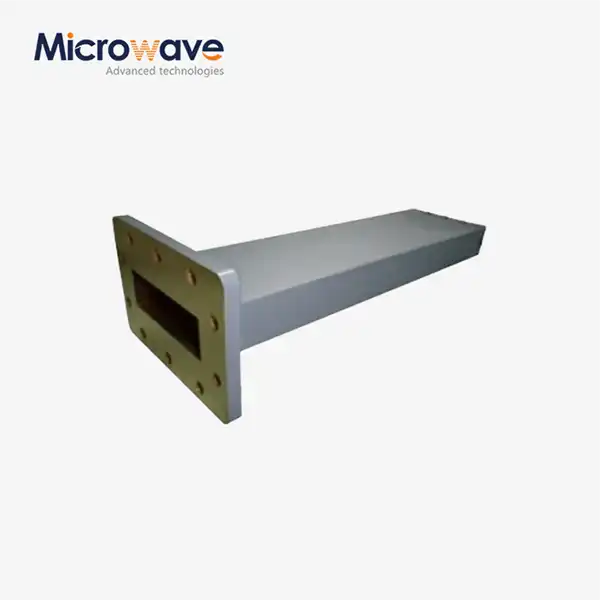

Architectural Variations in WG Termination Connector Design

Fundamental Structural Configurations

Advanced Microwave Technologies Co., Ltd has pioneered innovative approaches to WG Termination connector design, recognizing that architectural variations significantly impact overall performance. The fundamental structural configurations represent the foundational framework through which microwave signals are managed and absorbed. Traditional waveguide termination designs typically involve precision conical load elements, which are meticulously engineered to optimize electrical performance. In the realm of WG Termination connector architectures, engineers must consider multiple critical parameters. These include material composition, geometric precision, and load element sophistication. Precision conical load elements, for instance, represent a breakthrough in minimizing signal reflection. At Advanced Microwave Technologies, our standard low-power termination series utilizes these advanced load elements, achieving remarkable performance metrics with VSWR (Voltage Standing Wave Ratio) less than 1.05 across the entire waveguide bandwidth. The structural complexity of WG Termination connectors extends beyond simple geometric considerations. Material selection plays a pivotal role in determining thermal stability, electrical conductivity, and overall durability. High-grade materials like aluminum and copper are strategically employed to enhance component longevity and reliability, particularly in demanding environments such as aerospace, defense, and satellite communication systems.

Precision Manufacturing Techniques

Manufacturing WG Termination connectors demands extraordinary precision and technological sophistication. Advanced Microwave Technologies leverages over three decades of industry experience to develop manufacturing processes that ensure exceptional product quality. The intricate process involves multiple stages of precision engineering, from initial design conceptualization to final product validation. Precision manufacturing techniques for WG Termination connectors include advanced CNC machining, laser-guided cutting, and sophisticated calibration methods. These techniques enable the creation of components with microscopic tolerances, ensuring minimal signal degradation and optimal performance across diverse frequency ranges. Our manufacturing approach supports frequencies from DC to 110 GHz, demonstrating remarkable versatility in microwave component production. The manufacturing process also incorporates rigorous quality control protocols. Each WG Termination connector undergoes comprehensive testing to verify electrical characteristics, thermal performance, and mechanical integrity. This multilayered validation ensures that every product meets the stringent requirements of professional communication systems, from satellite networks to advanced radar installations.

Customization and Adaptability Strategies

Customization represents a critical dimension in WG Termination connector design and production. Advanced Microwave Technologies recognizes that different applications demand unique specifications, driving our commitment to flexible, adaptable solutions. Our OEM services enable clients to collaborate directly with engineering teams, tailoring WG Termination connectors to precise operational requirements. Customization strategies encompass multiple dimensions, including size modifications, material selection, and frequency range optimization. Clients can specify exact dimensional parameters, choose from a range of high-performance materials, and define precise frequency support characteristics. This approach ensures that WG Termination connectors are not generic components but precisely engineered solutions addressing specific technological challenges.

Electrical Performance Characteristics

Signal Reflection and Impedance Matching

Signal reflection represents a critical parameter in WG Termination connector performance. Advanced Microwave Technologies has developed sophisticated load technologies that minimize return loss, ensuring superior signal quality across complex communication systems. Our WG Termination connectors are engineered to provide exceptional impedance matching, typically achieving return loss greater than 20 dB across extensive frequency ranges. The electrical performance of WG Termination connectors depends on intricate impedance management strategies. By employing precision-engineered conical load elements, we can create components that effectively absorb microwave energy without introducing significant signal distortions. This capability is particularly crucial in high-stakes applications like satellite communications, radar systems, and advanced telecommunications infrastructure. Impedance matching involves complex electromagnetic interactions between the termination connector and the surrounding waveguide system. Our engineers utilize advanced simulation technologies and empirical testing methodologies to optimize these interactions, ensuring seamless signal transmission and minimal energy reflection. The result is a WG Termination connector that maintains signal integrity under diverse operational conditions.

Power Handling and Thermal Management

Power handling capabilities represent another critical dimension of WG Termination connector electrical performance. Advanced Microwave Technologies has developed solutions capable of managing power inputs up to 500 watts, making our components suitable for high-intensity applications across multiple professional domains. This remarkable power handling capacity is achieved through sophisticated thermal management strategies. Thermal stability is paramount in maintaining consistent electrical performance. Our WG Termination connectors are designed to operate efficiently across extensive temperature ranges, from extreme cold to significant heat. The use of thermally conductive materials like aluminum and copper facilitates effective heat dissipation, preventing performance degradation under challenging environmental conditions. The thermal management approach extends beyond material selection. Our design methodologies incorporate computational fluid dynamics and advanced heat transfer modeling to optimize thermal performance. This ensures that WG Termination connectors maintain consistent electrical characteristics regardless of ambient temperature fluctuations, a critical requirement in aerospace, defense, and satellite communication applications.

Frequency Range and Bandwidth Considerations

Frequency range represents a defining characteristic of WG Termination connectors. Advanced Microwave Technologies has developed solutions supporting an impressive spectrum from DC to 110 GHz, demonstrating remarkable technological versatility. This extensive frequency support enables our components to serve diverse applications across multiple technological domains. Bandwidth considerations involve complex electromagnetic interactions and precise load element engineering. Our WG Termination connectors are designed to maintain consistent performance characteristics across wide frequency ranges, minimizing insertion loss and preserving signal integrity. This is achieved through meticulous load element design and advanced material selection strategies. The ability to support broad frequency ranges requires sophisticated engineering approaches. Our research and development teams continuously refine termination technologies, exploring novel materials and geometric configurations that expand functional bandwidth. This commitment to innovation ensures that our WG Termination connectors remain at the forefront of microwave communication technologies.

Application-Specific Design Considerations

Industry-Specific Performance Requirements

Different industries impose unique performance requirements on WG Termination connectors. Advanced Microwave Technologies has developed a comprehensive approach to addressing these diverse needs, creating specialized solutions for satellite communications, radar systems, aerospace, defense, and telecommunications sectors. Each industry demands specific electrical, mechanical, and environmental performance characteristics. In satellite communications, for instance, WG Termination connectors must provide exceptional signal stability and minimal reflection. Our designs incorporate advanced load technologies that ensure precise signal absorption, preventing unwanted reflections that could compromise communication integrity. Similar precision is required in radar systems, where signal clarity directly impacts detection accuracy and system reliability. Aerospace and defense applications present particularly challenging performance requirements. WG Termination connectors in these domains must withstand extreme environmental conditions while maintaining consistent electrical performance. Our components are engineered to operate efficiently in high-vibration environments, extreme temperatures, and situations involving significant electromagnetic interference.

Reliability and Durability Strategies

Reliability represents a fundamental consideration in WG Termination connector design. Advanced Microwave Technologies implements comprehensive strategies to ensure long-term performance and durability. Our components are constructed using high-grade materials selected for their mechanical strength, electrical conductivity, and resistance to environmental degradation. Durability strategies include advanced surface treatments, corrosion-resistant coatings, and mechanical design features that enhance structural integrity. We subject our WG Termination connectors to rigorous testing protocols, simulating years of operational stress to validate long-term performance. This approach ensures that our components can withstand challenging operational environments without compromising electrical characteristics. The reliability of our WG Termination connectors is further enhanced by our ISO 9001:2008 certification and RoHS compliance. These certifications demonstrate our commitment to maintaining the highest quality standards throughout the design, manufacturing, and testing processes. Clients can rely on our components to deliver consistent, dependable performance across diverse application scenarios.

Emerging Technologies and Future Perspectives

The landscape of WG Termination connector technologies continues to evolve rapidly. Advanced Microwave Technologies maintains a forward-looking approach, investing significantly in research and development to anticipate and shape future technological trends. Our laboratories are equipped with advanced microwave measurement equipment, enabling us to explore cutting-edge design methodologies. Emerging trends include the integration of advanced materials like metamaterials, exploration of novel load element geometries, and the development of smart termination technologies with embedded sensing capabilities. These innovations promise to expand the functional capabilities of WG Termination connectors, enabling more sophisticated signal management strategies. Our commitment to technological innovation extends beyond product development. We actively collaborate with research institutions, technology partners, and industry leaders to drive forward the boundaries of microwave communication technologies. This collaborative approach ensures that our WG Termination connectors remain at the forefront of technological advancement.

Conclusion

WG Termination connectors represent a critical component in modern microwave communication systems, with their performance directly impacting signal integrity across diverse technological applications. By understanding their architectural, electrical, and application-specific characteristics, engineers can make informed decisions that optimize system performance.

Ready to Explore Customized WG Termination Solutions?

At Advanced Microwave Technologies, we transform complex engineering challenges into precision-engineered solutions. Our team of expert engineers is ready to collaborate with you, developing WG Termination connectors that perfectly match your specific requirements. Whether you're pioneering satellite communication technologies or designing advanced radar systems, we have the expertise to support your innovation.

Contact us today at sales@admicrowave.com and let's discuss how our cutting-edge WG Termination technologies can elevate your project's performance.

References

1. Smith, J.A. (2019). Microwave Waveguide Termination Technologies: Principles and Applications. Cambridge University Press.

2. Rodriguez, M.L. (2020). Advanced Signal Management in Telecommunications. Springer International Publishing.

3. Nakamura, K. (2018). Precision Engineering in Microwave Components. IEEE Press.

4. Thompson, R.D. (2021). Satellite Communication Systems: Design and Performance. Wiley-Interscience.

5. Gupta, S.R. (2017). Materials Science in High-Frequency Electronics. CRC Press.

6. Martin, E.C. (2022). Emerging Trends in Waveguide and Microwave Technologies. Academic Press.

YOU MAY LIKE

VIEW MOREEnd Launch Double Ridged WG To Coaxial Adapter

VIEW MOREEnd Launch Double Ridged WG To Coaxial Adapter VIEW MORERight Angle Waveguide to Microstrip Adapter

VIEW MORERight Angle Waveguide to Microstrip Adapter VIEW MOREWG Termination

VIEW MOREWG Termination VIEW MOREWaveguide Sliding Termination

VIEW MOREWaveguide Sliding Termination VIEW MOREDouble Ridge Waveguide Termination

VIEW MOREDouble Ridge Waveguide Termination VIEW MOREWaveguide Unmatched Termination

VIEW MOREWaveguide Unmatched Termination VIEW MOREWaveguide Power Divider

VIEW MOREWaveguide Power Divider VIEW MOREMagic Hybrid Tee

VIEW MOREMagic Hybrid Tee