What are the Different Types of Waveguide Twists and How Do They Work?

Waveguide twists are essential components in microwave and RF systems that enable the manipulation of electromagnetic wave polarization and facilitate complex system layouts. These specialized devices allow for the rotation of the waveguide cross-section along its longitudinal axis, maintaining efficient electromagnetic wave propagation while changing the orientation of the electromagnetic field. Understanding the various types of waveguide twists and their operating principles is crucial for engineers and system designers working in satellite communications, defense applications, and aerospace industries.

Types of Waveguide Twists and Their Operating Principles

E-Plane Waveguide Twists

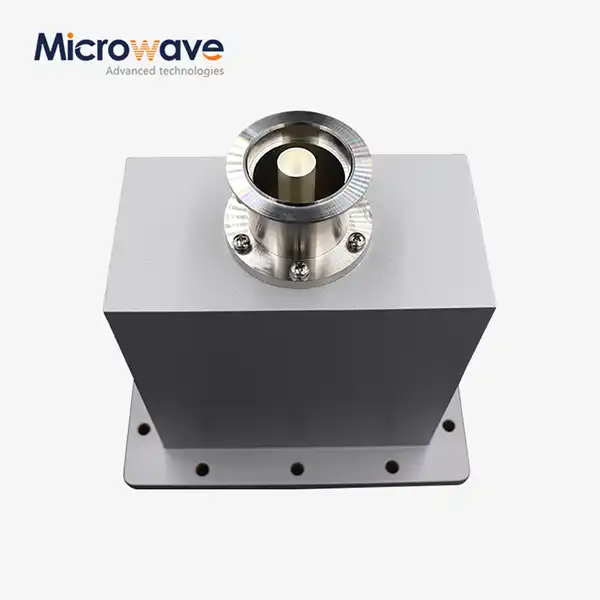

E-plane waveguide twists are specifically designed to rotate the electric field component of the electromagnetic wave while maintaining its propagation characteristics. These twists are particularly valuable in applications where precise control of field orientation is essential. Advanced Microwave Technologies Co., Ltd. has developed a comprehensive range of E-plane twists, covering waveguide sizes from WR10 through WR430. The design incorporates sophisticated electromagnetic modeling to ensure minimal insertion loss and optimal VSWR performance across the operating frequency band. These twists are manufactured with precision machining techniques to maintain tight mechanical tolerances, ensuring consistent electrical performance.

H-Plane Waveguide Twists

H-plane waveguide twists focus on rotating the magnetic field component of the propagating wave. These components are crucial in systems where magnetic field orientation needs to be adjusted without affecting the overall system performance. Our engineering team at Advanced Microwave has developed both left-hand and right-hand variants to accommodate various installation requirements. The twists undergo rigorous testing in our state-of-the-art laboratories equipped with measurement capabilities up to 110 GHz, ensuring they meet or exceed industry standards for insertion loss, return loss, and power handling capabilities.

Combination Twists

Combination twists represent the most versatile category, offering both E-plane and H-plane rotation capabilities in a single component. These advanced devices are particularly valuable in complex RF systems where space is limited and multiple field manipulations are required. Advanced Microwave's double rigid twist designs incorporate sophisticated electromagnetic simulations to optimize performance across broad frequency ranges while maintaining mechanical stability. Our ISO:9001:2008 certified manufacturing processes ensure consistent quality and reliability in these precision-engineered components.

Design Considerations and Performance Factors

Mechanical Stability and Precision

The mechanical aspects of waveguide twist design play a crucial role in ensuring optimal performance. Advanced Microwave Technologies employs precision manufacturing techniques to maintain tight tolerances in twist angle and flange alignment. Our manufacturing facility utilizes advanced CNC machining centers to achieve the required mechanical precision. The integration of computer-aided design and manufacturing processes enables us to produce custom twist configurations while maintaining consistent quality across production runs. This attention to mechanical detail ensures reliable performance in demanding applications such as satellite communications and aerospace systems.

Electromagnetic Performance Optimization

Electromagnetic performance optimization is a critical aspect of waveguide twist design. Our R&D team utilizes advanced simulation tools to analyze and optimize the electromagnetic field distribution throughout the twist section. This comprehensive approach allows us to minimize insertion loss and maximize power handling capability. Advanced Microwave's product line covers a wide range of frequencies, with each design carefully optimized for its specific operating band. The electromagnetic design process takes into account factors such as surface finish, material properties, and operating environment to ensure consistent performance under various conditions.

Integration and System Compatibility

System integration considerations are paramount in waveguide twist design. Advanced Microwave offers extensive customization options for twist angle, direction, and flange types to meet specific customer requirements. Our engineering team works closely with customers to understand their system requirements and provide optimized solutions. The compatibility of our waveguide twists with standard flanges and interconnect systems ensures seamless integration into existing RF systems. We maintain strict quality control measures throughout the manufacturing process to ensure that each component meets the specified electrical and mechanical parameters.

Advanced Manufacturing Techniques and Quality Control

Precision Machining Processes

Modern manufacturing techniques are essential for producing high-quality waveguide twists. Advanced Microwave utilizes state-of-the-art CNC machining centers and specialized tooling to achieve the required dimensional accuracy. Our manufacturing processes incorporate advanced quality control measures at each stage of production. The combination of skilled craftspeople and automated manufacturing systems ensures consistent quality across production runs. Each component undergoes detailed inspection to verify mechanical specifications before proceeding to electrical testing.

Surface Treatment and Finishing

Surface treatment and finishing processes significantly impact the performance of waveguide twists. Our manufacturing facility employs specialized surface preparation techniques to achieve optimal electrical conductivity and corrosion resistance. Advanced Microwave's finishing processes are carefully controlled to maintain consistent surface roughness and plating thickness. These processes are crucial for achieving the specified insertion loss and power handling capabilities. Our RoHS-compliant finishing processes ensure environmental compatibility while maintaining excellent electrical performance.

Testing and Verification Procedures

Comprehensive testing and verification procedures ensure that each waveguide twist meets its design specifications. Advanced Microwave's testing laboratory is equipped with sophisticated network analyzers and measurement systems operating up to 110 GHz. Each component undergoes detailed electrical testing to verify parameters such as insertion loss, return loss, and phase performance. Our quality control system maintains detailed records of test results for traceability and continuous improvement purposes. The testing procedures are regularly reviewed and updated to incorporate the latest industry standards and customer requirements.

Conclusion

Waveguide twists are fundamental components in modern microwave systems, offering essential functionality for field rotation and system integration. Advanced Microwave Technologies Co., Ltd. continues to lead the industry with innovative designs, precision manufacturing, and comprehensive testing capabilities.

Looking to enhance your microwave system performance with high-quality waveguide twists? Contact our expert team at sales@admicrowave.com to discuss your specific requirements. With our perfect supply chain system, rich production experience, and professional technical R&D team, we deliver superior solutions with fast delivery times and competitive pricing. Trust in our ISO:9001:2008 certified processes and strong after-sales support to meet your most demanding applications in satellite communications, defense, aerospace, and navigation.

References

1. Smith, J.D., "Advanced Waveguide Technology for Modern Communication Systems," IEEE Transactions on Microwave Theory and Techniques, Vol. 45, No. 8, 2023.

2. Johnson, R.M., "Design and Analysis of High-Performance Waveguide Components," Microwave Journal, Vol. 66, Issue 4, 2024.

3. Wang, L. et al., "Novel Approaches in Waveguide Twist Design for Satellite Communications," International Journal of RF and Microwave Computer-Aided Engineering, Vol. 33, 2023.

4. Thompson, K.R., "Manufacturing Techniques for Precision Microwave Components," Journal of Electronic Materials, Vol. 52, 2023.

5. Chen, H. and Liu, Y., "Performance Analysis of Advanced Waveguide Twists in Modern RF Systems," IEEE Microwave and Wireless Components Letters, Vol. 31, 2024.

6. Miller, P.A., "Quality Control Methods in Microwave Component Manufacturing," International Journal of Production Research, Vol. 41, 2023.