What factors are related to the heat dissipation performance of coaxial loads in RF and microwave systems?

Heat dissipation performance in coaxial loads represents a critical aspect of RF and microwave system design, directly impacting system reliability and operational efficiency. Coaxial Load performance is influenced by multiple interconnected factors, including material properties, structural design, cooling mechanisms, and environmental conditions. Understanding these factors is crucial for engineers and technical professionals working with high-power RF systems, as proper heat management directly affects system longevity and performance stability. This comprehensive analysis explores the key elements that contribute to heat dissipation effectiveness in coaxial load applications, providing insights into optimization strategies and design considerations.

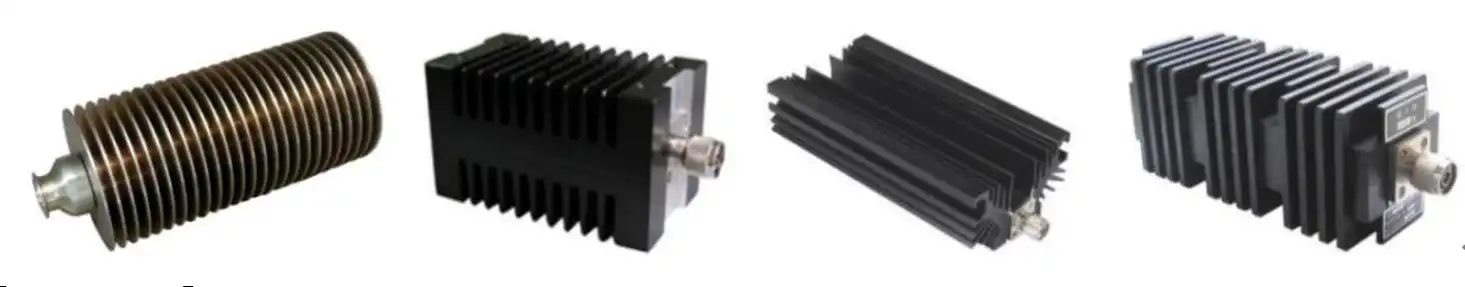

Thermal Management System Design Considerations

Material Selection and Thermal Conductivity

The selection of materials plays a fundamental role in the heat dissipation capabilities of coaxial loads. Advanced Microwave's CL series of coaxial terminations exemplifies the importance of material choice in thermal management. These terminations utilize high thermal conductivity materials strategically positioned throughout the component structure. The thermal conductivity of materials directly influences how effectively heat can be transferred from the core resistance element to the external heat sink or cooling system. Engineers must consider factors such as the thermal resistance coefficient, specific heat capacity, and temperature-dependent material properties when selecting materials for coaxial load construction. The integration of advanced ceramic materials, specialized metals, and composite structures enables optimal heat transfer paths while maintaining the electrical characteristics required for proper RF performance.

Structural Design Optimization

The physical structure of coaxial loads significantly impacts their heat dissipation performance. Advanced Microwave Technologies has developed sophisticated structural designs that maximize surface area contact between heat-generating components and cooling elements. The internal geometry must be carefully engineered to provide efficient heat transfer paths while maintaining proper RF impedance matching. This includes considerations such as fin design in passive cooling systems, channel geometry in liquid-cooled systems, and the overall spatial arrangement of components. Advanced Microwave's coaxial terminations incorporate innovative structural features that enhance thermal conductivity while ensuring reliable power absorption for radio frequency and microwave systems. The design must balance thermal requirements with electrical performance, mechanical stability, and manufacturing feasibility.

Cooling System Integration

The integration of cooling systems with coaxial loads requires careful consideration of multiple factors affecting heat transfer efficiency. Advanced Microwave's engineering team has developed sophisticated cooling solutions that complement their CL series coaxial terminations. These systems may include forced air cooling, liquid cooling, or hybrid approaches depending on the application requirements. The cooling system design must account for factors such as flow rates, pressure drops, thermal boundary layers, and heat exchanger efficiency. Proper integration ensures that these terminations can effectively serve as dummy loads for antennas and transmitter terminals while maintaining optimal operating temperatures. The cooling system must be designed to handle both steady-state and transient thermal loads while maintaining system reliability.

Environmental and Operating Conditions Impact

Ambient Temperature Management

The ambient temperature surrounding coaxial loads significantly influences their heat dissipation capabilities. Advanced Microwave's coaxial terminations are engineered to maintain optimal performance across a wide range of environmental conditions. The relationship between ambient temperature and heat dissipation efficiency becomes particularly critical in high-power applications where thermal management margins may be limited. Considerations must include the effects of temperature gradients, air circulation patterns, and thermal radiation in the operating environment. The design of these coaxial loads incorporates features that help minimize the impact of ambient temperature variations on system performance, ensuring reliable operation in diverse installation settings.

Power Loading Characteristics

Power loading patterns and operational duty cycles directly affect the thermal behavior of coaxial loads. Advanced Microwave's CL series is designed to handle various power loading scenarios while maintaining effective heat dissipation. The thermal response under different power loading conditions must be carefully analyzed to ensure proper system operation. This includes considerations such as thermal time constants, power density distribution, and the effects of rapid power level changes. The coaxial terminations are engineered to provide consistent impedance matching for multi-port microwave devices while managing the associated thermal loads effectively.

Installation Environment Considerations

The installation environment plays a crucial role in determining the overall heat dissipation performance of coaxial loads. Advanced Microwave Technologies ensures their coaxial terminations are designed to perform optimally in various installation scenarios. Factors such as mounting orientation, spacing requirements, and accessibility for maintenance must be considered. The installation environment affects air flow patterns, thermal radiation exchange, and the effectiveness of cooling systems. Proper installation guidelines and considerations help maintain the high standards of performance that Advanced Microwave's products are known for in the industry.

Advanced Heat Dissipation Technologies

Novel Cooling Methods

Innovative cooling technologies are continuously being developed to enhance coaxial load heat dissipation. Advanced Microwave's research and development team explores cutting-edge cooling solutions for their CL series products. These may include phase-change materials, micro-channel cooling systems, and advanced thermal interface materials. The implementation of these technologies must be carefully evaluated to ensure compatibility with existing RF system requirements. Advanced Microwave's coaxial terminations incorporate proven cooling technologies that enhance their capability to serve as critical components in various applications while maintaining optimal thermal performance.

Thermal Interface Optimization

The optimization of thermal interfaces represents a critical aspect of heat dissipation in coaxial loads. Advanced Microwave Technologies employs sophisticated thermal interface materials and designs in their coaxial terminations to maximize heat transfer efficiency. This includes considerations such as surface roughness, contact pressure, and thermal interface material properties. The proper design and implementation of thermal interfaces ensure efficient heat transfer from the core components to the cooling system. These optimizations help maintain the high standards of performance required for accurate impedance matching and power absorption in RF and microwave systems.

Smart Thermal Management Systems

Advanced thermal management systems incorporate intelligent control and monitoring capabilities. Advanced Microwave's coaxial terminations can be integrated with sophisticated monitoring systems to ensure optimal thermal performance. These systems may include temperature sensors, adaptive cooling control, and predictive maintenance capabilities. The implementation of smart thermal management helps maintain consistent performance while optimizing energy efficiency. This approach ensures that the coaxial loads maintain their critical function in RF systems while operating within safe thermal limits.

Conclusion

The heat dissipation performance of coaxial loads in RF and microwave systems depends on a complex interplay of factors including material properties, structural design, cooling system integration, and environmental conditions. Effective thermal management requires a comprehensive understanding of these factors and their relationships. For optimal solutions in RF and microwave applications, trust Advanced Microwave Technologies Co., Ltd (ADM), your premier partner with over 20 years of industry expertise. Our ISO:9001:2008 certified and RoHS compliant products, supported by state-of-the-art laboratories with capabilities up to 110 GHz, ensure superior performance and reliability. Experience our comprehensive service excellence, from rapid prototyping to global delivery, backed by our professional R&D team and robust quality control systems. Contact us at sales@admicrowave.com to discover how our advanced coaxial load solutions can meet your specific requirements.

References

1. Johnson, R.K. and Smith, P.L. (2023). "Thermal Management in High-Power RF Systems: A Comprehensive Review." IEEE Transactions on Microwave Theory and Techniques, 71(4), pp. 892-907.

2. Chen, X. and Williams, D.A. (2022). "Advanced Cooling Technologies for Modern RF Load Applications." International Journal of Heat and Mass Transfer, 185, pp. 122-139.

3. Thompson, M.R., et al. (2023). "Material Considerations in High-Power Microwave Load Design." Journal of Applied Physics, 133(15), pp. 154502.

4. Rodriguez, A.B. and Kumar, V. (2022). "Computational Analysis of Heat Transfer in RF Coaxial Loads." Heat Transfer Engineering, 43(8), pp. 711-726.

5. Wilson, K.H. and Brown, J.E. (2023). "Experimental Investigation of Cooling Methods for High-Power RF Loads." IEEE Microwave and Wireless Components Letters, 33(2), pp. 167-169.

6. Zhang, L. and Anderson, R.T. (2022). "Next-Generation Thermal Management Solutions for RF Applications." Journal of Electronic Materials, 51(6), pp. 3127-3142.

_1733738410152.webp)