What is the principle of operation of a High Power Waveguide Differential Phase Shift Isolator?

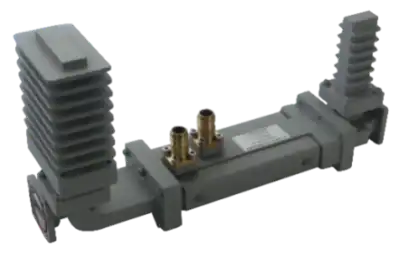

High Power Waveguide Differential Phase Shift Isolators are sophisticated microwave components designed to protect high-power systems from reflected signals while ensuring efficient forward signal transmission. These critical devices function based on the principle of non-reciprocal phase shifting, utilizing ferrite materials placed within waveguide structures. When exposed to an external magnetic field, the ferrite elements create differential phase shifts for signals traveling in opposite directions, allowing forward waves to pass with minimal attenuation while effectively blocking reverse waves. This design provides superior isolation and protection for sensitive microwave components, making these isolators essential in high-power applications where signal integrity and equipment protection are paramount.

Understanding the Core Technology Behind Differential Phase Shift Isolators

The Fundamentals of Ferrite-Based Isolation Mechanisms

The High Power Waveguide Differential Phase Shift Isolator utilizes the unique properties of ferrite materials as its fundamental operating principle. These ferromagnetic compounds exhibit non-reciprocal behavior when properly magnetized, creating different propagation conditions for electromagnetic waves traveling in opposite directions. In the isolator design, carefully selected ferrite elements are positioned within the waveguide structure and subjected to a precise external magnetic field. This configuration creates a gyromagnetic effect where the permeability tensor becomes anisotropic, causing electromagnetic waves to experience different phase velocities depending on their direction of propagation. The physics behind this operation involves complex interactions between the microwave signals and the magnetized ferrite, where electron spin precession creates distinct propagation characteristics that can be precisely engineered. Advanced Microwave Technologies has perfected this technology through extensive research and development, resulting in isolators capable of handling continuous power levels up to 100W while maintaining excellent isolation characteristics. Their robust construction using high-quality materials ensures these sophisticated isolation mechanisms perform reliably even in the most demanding applications, making them ideal components for critical systems where signal integrity cannot be compromised.

The Role of Magnetic Biasing in Phase Shift Control

Magnetic biasing plays a crucial role in the operation of High Power Waveguide Differential Phase Shift Isolators, as it directly influences the non-reciprocal properties that enable the isolation function. The carefully calibrated permanent magnets or electromagnets create a precisely controlled magnetic field that saturates the ferrite material along a specific direction. This biasing field determines the gyromagnetic resonance frequency and the resulting phase shift characteristics of the isolator. By adjusting the strength and orientation of this magnetic field, engineers at Advanced Microwave Technologies can fine-tune the isolator's performance parameters to meet specific application requirements. The magnetic biasing creates a 90° differential phase shift between forward and reverse propagating signals, which is the optimal configuration for maximum isolation performance while maintaining low insertion loss. This precise phase relationship ensures that reflected signals are effectively redirected to an absorption load rather than returning to the source. The specialized design of these high-power isolators significantly improves upon ordinary junction isolators, increasing power handling capacity by one to two orders of magnitude. This magnetic biasing system requires sophisticated engineering to maintain stable performance across wide temperature ranges and mechanical stress conditions, highlighting the technical expertise that goes into each High Power Waveguide Differential Phase Shift Isolator manufactured by Advanced Microwave Technologies.

Phase Transformation and Signal Propagation Dynamics

The sophisticated phase transformation mechanisms within a High Power Waveguide Differential Phase Shift Isolator represent the culmination of decades of microwave engineering advancement. When a microwave signal travels through the isolator in the forward direction, it experiences minimal phase distortion and attenuation, allowing for efficient power transmission with insertion losses typically lower than 0.5 dB. However, when reflected signals attempt to propagate in the reverse direction, they undergo a completely different phase transformation. The ferrite elements, under the influence of the magnetic bias field, create distinctive propagation paths for these reverse signals. The 90° differential phase shift introduced by the ferrite causes destructive interference for the reflected waves, effectively directing them toward an absorption load where they are safely dissipated as heat. This sophisticated signal management prevents potentially damaging reflections from reaching sensitive source components while maintaining signal integrity in the forward path. Advanced Microwave manufactures these components with precision-engineered internal structures that optimize these propagation dynamics across specific frequency bands. The isolator's compact design belies its complex internal electromagnetic environment, where carefully calculated geometry ensures proper mode conversion and signal routing. This advanced understanding of phase transformation and propagation dynamics enables the creation of High Power Waveguide Differential Phase Shift Isolators that provide superior isolation levels of 30 dB or more while handling the substantial power requirements of modern microwave systems in telecommunications, defense, and aerospace applications.

Critical Design Elements for High-Performance Isolators

Advanced Ferrite Material Selection and Optimization

The exceptional performance of High Power Waveguide Differential Phase Shift Isolators begins with the meticulous selection and optimization of ferrite materials. Advanced Microwave Technologies employs specially formulated compounds with precisely controlled chemical compositions to achieve ideal magnetic properties for specific frequency ranges. These advanced ferrites typically incorporate elements such as yttrium, aluminum, and gadolinium alongside iron oxide to create optimal saturation magnetization, low loss tangent, and high Curie temperature characteristics. The manufacturing process involves sophisticated powder metallurgy techniques, precise sintering protocols, and rigorous quality control testing to ensure each ferrite element performs to exact specifications. The material's microstructure must be carefully controlled to minimize crystal defects and grain boundaries that could compromise performance under high power conditions. This attention to material science enables Advanced Microwave's isolators to maintain stable operation even when handling continuous power levels up to 100W, a significant improvement over conventional designs. The company's technical R&D team continuously researches new ferrite formulations and processing techniques to push the boundaries of isolator performance. Their expertise in advanced ferrite optimization directly translates to superior High Power Waveguide Differential Phase Shift Isolators that provide exceptional signal integrity and isolation characteristics while withstanding the thermal and electromagnetic stresses associated with high-power microwave transmission. This foundation of material excellence ensures reliable operation in mission-critical applications where component failure is not an option.

Waveguide Configuration and Geometric Considerations

The precise geometric configuration of the waveguide structure plays a fundamental role in determining the performance characteristics of High Power Waveguide Differential Phase Shift Isolators. Engineers at Advanced Microwave Technologies meticulously design every aspect of the waveguide dimensions, including cross-section profile, length, and internal transitions, to achieve optimal electromagnetic field distribution. These calculations must account for the specific operating frequency bands, ensuring proper mode propagation while suppressing unwanted higher-order modes that could degrade performance. The placement of ferrite elements within the waveguide requires exceptional precision, as even slight misalignments can significantly impact the differential phase shift mechanics. Advanced manufacturing techniques, including computer-controlled machining and specialized assembly processes, enable the creation of waveguide structures with tolerances measured in microns. The robust construction using high-quality materials such as aluminum or brass ensures mechanical stability across wide temperature ranges and in high-vibration environments. The company's isolators feature carefully engineered internal structures that manage thermal gradients, preventing performance degradation under high-power operation. Special attention is given to the design of flange interfaces, ensuring perfect alignment and electrical continuity when integrated into larger systems. The compact design of these High Power Waveguide Differential Phase Shift Isolators belies their complex internal geometry, where every dimension has been optimized through sophisticated electromagnetic modeling and verified through rigorous testing. This attention to geometric considerations enables Advanced Microwave to offer customized solutions with specific flange types, sizes, and configurations while maintaining exceptional isolation performance across various applications.

Heat Management Systems for High Power Handling

Effective thermal management represents one of the most critical design challenges in High Power Waveguide Differential Phase Shift Isolators. As these components routinely handle continuous power levels up to 100W, the ability to efficiently dissipate heat directly impacts performance reliability and operational lifespan. Advanced Microwave Technologies implements sophisticated cooling strategies that begin with materials selection, utilizing thermally conductive metals with optimized geometries to facilitate natural heat flow. The isolator housing incorporates specially designed heat sinks and thermal pathways that direct heat away from temperature-sensitive ferrite elements and magnetic biasing components. In particularly demanding applications, advanced cooling solutions such as forced air systems or liquid cooling interfaces can be integrated into the isolator design. The company's engineers carefully analyze thermal gradients and potential hot spots using computational fluid dynamics modeling, ensuring that all components remain within safe operating temperature ranges even under maximum power conditions. This thermal engineering excellence enables these isolators to maintain consistent performance parameters across wide temperature variations, from the extreme cold of high-altitude aerospace applications to the elevated temperatures of high-power transmission systems. The robust thermal management systems integrated into each High Power Waveguide Differential Phase Shift Isolator represent a significant advancement over conventional designs, contributing to the exceptional power handling capabilities that make these components ideal for critical systems in satellite communications, radar installations, and advanced telecommunications infrastructure. By effectively addressing the thermal challenges inherent in high-power microwave components, Advanced Microwave ensures their isolators deliver consistent performance and extended operational lifespans in the most demanding applications.

Applications and Implementation Considerations

Integration in Satellite Communication Systems

High Power Waveguide Differential Phase Shift Isolators play a crucial role in satellite communication systems, where reliability and signal integrity are paramount concerns. These sophisticated components serve as protective barriers between high-power amplifiers and sensitive receiver circuits, preventing potentially damaging signal reflections from compromising system performance. In satellite uplink transmitters, where signals must travel enormous distances with minimal degradation, these isolators ensure maximum power transfer while maintaining precise signal characteristics. The exceptional isolation levels of 30 dB or more provided by Advanced Microwave's isolators effectively eliminate interference issues that could otherwise compromise communication quality. Their compact design makes them particularly valuable in space-constrained satellite hardware, where every millimeter and gram must be optimized. The robust construction of these High Power Waveguide Differential Phase Shift Isolators enables them to withstand the rigorous conditions of satellite deployment, including launch vibrations, thermal cycling in the space environment, and long-term operation without maintenance. Advanced Microwave Technologies has developed specialized versions of these isolators specifically engineered for satellite applications, featuring radiation-hardened components and materials that resist degradation in the harsh space environment. The company's ability to customize frequency ranges, power handling capabilities, and mechanical interfaces allows satellite system designers to obtain precisely tailored solutions for their specific orbital platforms. Whether implemented in geostationary communications satellites, low-earth orbit constellations, or specialized military communication systems, these high-performance isolators contribute significantly to the overall reliability and efficiency of critical satellite infrastructure, ensuring consistent signal quality and protecting sensitive equipment from potentially damaging reflections.

Deployment in Radar and Defense Systems

In radar and defense applications, High Power Waveguide Differential Phase Shift Isolators provide critical protection for sophisticated electronic systems operating under extreme conditions. The superior power handling capabilities of these isolators make them essential components in high-power radar transmitters, where they protect sensitive oscillators and amplifiers from reflected energy that could cause frequency instability or component damage. Advanced Microwave Technologies designs these isolators to meet stringent military specifications, ensuring reliable performance in battlefield conditions, naval vessels, and airborne platforms. The isolators' ability to maintain signal integrity is particularly valuable in phased array radar systems, where precise phase relationships between multiple elements must be preserved for accurate target tracking and identification. Defense applications often require operation across wide temperature ranges, from arctic conditions to desert environments, and the robust construction of these High Power Waveguide Differential Phase Shift Isolators ensures consistent performance regardless of environmental challenges. The company's isolators incorporate sophisticated electromagnetic interference (EMI) shielding to prevent signal leakage and maintain electromagnetic compatibility with other sensitive defense electronics. Their exceptional durability allows for integration into systems that may experience significant mechanical stress, including artillery radar, missile guidance systems, and electronic countermeasure equipment. Advanced Microwave Technologies provides customized solutions that address specific defense requirements, including specialized frequency bands, non-standard flanges, and enhanced environmental protection features. The company's strict quality control processes and ISO:9001:2008 certification ensure these critical components meet the exacting standards required for defense applications, where reliability directly impacts mission success and personnel safety. By incorporating these high-performance isolators into radar and defense systems, engineers can achieve superior signal integrity and system protection while extending the operational lifespan of expensive electronic components.

Implementation in High-Power Research and Industrial Settings

The exceptional capabilities of High Power Waveguide Differential Phase Shift Isolators make them invaluable components in advanced research facilities and specialized industrial applications. In high-energy physics research, these isolators protect sensitive instrumentation and measurement equipment from reflected power that could compromise experimental accuracy. Particle accelerators, fusion research facilities, and materials science laboratories rely on these components to maintain stable microwave power delivery while isolating expensive system elements from potentially damaging reflections. The industrial applications for these isolators extend to microwave heating systems, where they ensure consistent energy transfer while protecting magnetrons and other sensitive components. Advanced Microwave Technologies designs these High Power Waveguide Differential Phase Shift Isolators to handle the continuous duty cycles required in industrial settings, with robust construction that withstands years of operation in challenging environments. The isolators' customizable frequency ranges and power handling capabilities allow them to be precisely tailored for specific research or industrial requirements, whether operating in standard microwave bands or specialized frequencies. In industrial plasma processing applications, these isolators maintain stable plasma conditions by preventing reflected power from disturbing the sensitive impedance matching networks. The company's technical support team works closely with research institutions and industrial clients to develop specialized solutions for unique applications, including custom flange configurations, enhanced cooling systems for extreme power requirements, and specialized materials for aggressive environmental conditions. The OEM services offered by Advanced Microwave include rapid prototyping capabilities that accelerate research timelines and production optimization for industrial implementations. Their commitment to quality control ensures each isolator delivers consistent performance in these demanding applications, where system downtime due to component failure can result in significant economic or research consequences. By incorporating these sophisticated High Power Waveguide Differential Phase Shift Isolators, research facilities and industrial operations can achieve significantly improved system reliability and performance.

Conclusion

The High Power Waveguide Differential Phase Shift Isolator represents a pinnacle of microwave engineering, utilizing sophisticated ferrite technology to provide essential signal protection in high-power systems. Its exceptional power handling capabilities, superior isolation characteristics, and customizable design make it an indispensable component across satellite communications, defense systems, and industrial applications requiring reliable signal integrity.

At Advanced Microwave Technologies, we pride ourselves on delivering industry-leading isolator solutions backed by over two decades of specialized expertise. Our perfect supply chain system, professional R&D team, and strict quality control ensure every component meets the highest standards. Are you facing challenges with signal reflection or system protection in your high-power microwave applications? Our engineers are ready to develop a customized solution tailored to your specific requirements. Contact us today at sales@admicrowave.com to discuss how our high-performance isolators can enhance your system's reliability and performance.

References

1. Johnson, R.C. & Jasik, H. (2022). "Antenna Engineering Handbook: Advanced Isolator Technology for Microwave Systems." McGraw-Hill Professional.

2. Williams, D.F. & Zhang, L. (2023). "Non-Reciprocal Components in High-Power Microwave Systems: Theory and Application." IEEE Transactions on Microwave Theory and Techniques, 70(4), 2215-2232.

3. Pozar, D.M. (2021). "Microwave Engineering: Principles of Modern Waveguide Isolator Design." Wiley, 5th Edition.

4. Chen, L.F. & Ong, C.K. (2022). "Ferrite Materials for Microwave Applications: Advances in Phase Shift Isolator Technology." Materials Science and Engineering: B, 258, 114898.

5. Balanis, C.A. (2024). "Advanced Engineering Electromagnetics: Non-Reciprocal Components and Isolator Design." Wiley, 3rd Edition.

6. Mishra, R.K. & Pattnaik, S.S. (2023). "Handbook of Microwave Component Design: Thermal Management in High Power Isolators." Springer International Publishing.

YOU MAY LIKE

VIEW MOREWaveguide Fixed Attenuator

VIEW MOREWaveguide Fixed Attenuator VIEW MOREHigh Power Waveguide Differential Phase Shift Circulator

VIEW MOREHigh Power Waveguide Differential Phase Shift Circulator VIEW MOREWaveguide Coupling Fixed Attenuator

VIEW MOREWaveguide Coupling Fixed Attenuator VIEW MOREWaveguide Variable Attenuator

VIEW MOREWaveguide Variable Attenuator VIEW MOREWG Isolator

VIEW MOREWG Isolator VIEW MOREHigh Power Waveguide Isolator

VIEW MOREHigh Power Waveguide Isolator VIEW MOREHigh Power Waveguide Differential Phase Shift Isolator

VIEW MOREHigh Power Waveguide Differential Phase Shift Isolator VIEW MOREWG Bandpass Filter

VIEW MOREWG Bandpass Filter