Are there standard sizes for Water-Cooled Twist Waveguides?

When it comes to high-power microwave transmission systems, understanding the standard sizes of Water-Cooled Twist Waveguides is crucial for system designers and engineers. Water-Cooled Twist Waveguides are specialized components that combine the functionality of traditional waveguide twists with advanced cooling capabilities. These components are manufactured according to international standards and specifications, typically following the WR (Waveguide Rectangular) designation system. The standard sizes range from WR-2300 to WR-28, with each size optimized for specific frequency bands and power handling capabilities. The incorporation of water cooling channels within these standardized dimensions enables these waveguides to handle significantly higher power levels while maintaining optimal performance.

Understanding Water-Cooled Twist Waveguide Specifications

Dimensional Standards and Tolerances

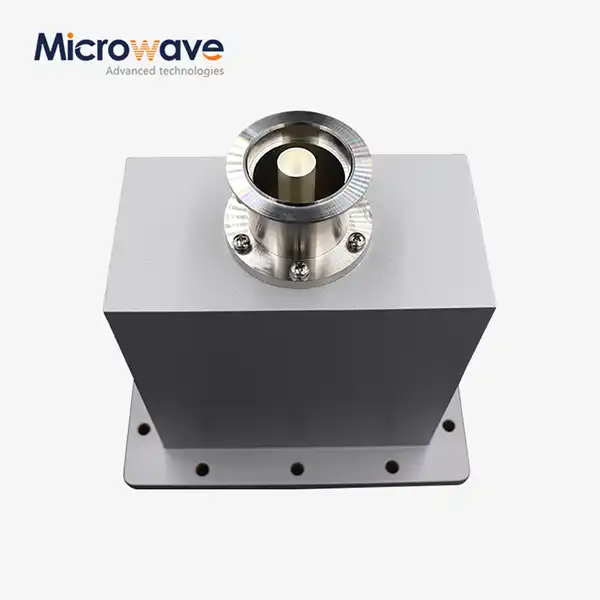

Water-cooled Twist Waveguide specifications are meticulously designed to meet industry requirements and international standards. Advanced Microwave Technologies Co., Ltd has developed a sophisticated water-cooling channel system that integrates seamlessly within standard waveguide dimensions. The water-cooled twist waveguide produced by Advanced Microwave features a precision-engineered cooling system that allows coolant circulation through carefully designed channels. This innovative design ensures optimal heat dissipation while maintaining the critical internal dimensions that affect microwave transmission characteristics. The manufacturing process involves tight tolerances, typically within ±0.001 inches for critical dimensions, ensuring consistent performance across all standard sizes. These precise specifications enable the waveguides to maintain their electrical properties while accommodating the additional complexity of the cooling system.

Frequency Range Considerations

The selection of appropriate Water-Cooled Twist Waveguide sizes is fundamentally linked to operating frequency requirements. Each standard size corresponds to a specific frequency band, with larger waveguides handling lower frequencies and smaller ones designed for higher frequencies. The water-cooled twist waveguide design incorporates cooling channels that are strategically positioned to minimize impact on the waveguide's electromagnetic performance. This sophisticated engineering ensures that the waveguide can work stably and reliably under high power conditions while maintaining optimal frequency response characteristics. The cooling system design takes into account the specific frequency-dependent loss mechanisms and power handling requirements, making these components ideal for applications in radar transmitters and other high-power systems.

Power Handling Capabilities

One of the most critical aspects of Water-Cooled Twist Waveguide specifications is their power handling capability. The water cooling system significantly enhances the power handling capacity compared to standard waveguides. Advanced Microwave's water-cooled twist waveguide design features an efficient cooling channel network that effectively manages heat distribution. The coolant circulation system is designed to maintain uniform temperature distribution, preventing hotspots and ensuring consistent performance. This enhanced thermal management capability allows these waveguides to handle power levels several times higher than their non-cooled counterparts, making them essential components in high-power microwave systems.

Design and Manufacturing Considerations

Material Selection and Properties

The manufacturing of Water-Cooled Twist Waveguides requires careful consideration of material properties and cooling efficiency. Advanced Microwave Technologies employs high-conductivity materials that optimize both electrical and thermal performance. The water-cooled twist waveguide design incorporates materials selected for their excellent thermal conductivity and mechanical stability. The cooling system utilizes specially designed channels that allow the coolant to circulate efficiently, taking away the heat generated during operation. These materials must maintain their properties under varying temperature conditions while ensuring minimal impact on the waveguide's electromagnetic characteristics. The combination of proper material selection and advanced cooling design ensures extended service life and maintains excellent electromagnetic transmission performance.

Cooling System Integration

The integration of cooling systems into twist waveguides represents a significant engineering challenge that requires precise design and manufacturing processes. Advanced Microwave's water-cooled twist waveguide incorporates a sophisticated cooling channel design that maximizes heat transfer efficiency while maintaining structural integrity. The cooling system is carefully integrated to ensure uniform temperature distribution and prevent thermal stress concentrations. The design of water channels considers factors such as flow rate, pressure drop, and heat transfer coefficients to optimize cooling performance. This integrated approach ensures that the waveguide can work stably and reliably under high power conditions, making it ideal for demanding applications in radar transmitters and other high-power systems.

Quality Control and Testing

Manufacturing Water-Cooled Twist Waveguides requires rigorous quality control procedures and comprehensive testing protocols. Advanced Microwave Technologies implements strict quality control measures throughout the production process. The water-cooled twist waveguide undergoes extensive testing to verify both its electromagnetic performance and cooling system efficiency. Each unit is subjected to pressure testing of the cooling channels, RF performance measurements, and thermal cycling tests to ensure reliability. The quality control process includes verification of dimensional accuracy, surface finish, and cooling system integrity. These comprehensive testing procedures ensure that each waveguide meets the stringent requirements for high-power microwave applications.

Applications and Performance Optimization

High-Power Radar Systems

Water-Cooled Twist Waveguides play a crucial role in modern radar systems where high power handling capability is essential. Advanced Microwave's water-cooled twist waveguide design is particularly well-suited for radar applications, featuring a robust cooling system that enables reliable operation at high power levels. The cooling channel design effectively manages the heat generated during radar transmission, ensuring stable performance and extended operational life. The waveguide's ability to maintain consistent electromagnetic properties while handling high power levels makes it ideal for continuous-wave radar systems and pulse radar applications. The integration of water cooling technology allows these waveguides to support the demanding requirements of modern radar systems while maintaining optimal performance characteristics.

Satellite Communication Systems

In satellite communication applications, Water-Cooled Twist Waveguides provide essential performance benefits for high-power transmission systems. Advanced Microwave Technologies' water-cooled twist waveguide incorporates advanced cooling technology that ensures reliable operation in satellite uplink stations and ground-based communication systems. The cooling system design allows for efficient heat dissipation, enabling the waveguide to handle the high power levels required for long-distance satellite communications. The carefully engineered cooling channels maintain stable operating temperatures, ensuring consistent signal quality and minimizing signal degradation. This design is particularly valuable in continuous operation scenarios where maintaining stable performance is crucial for reliable communication links.

Industrial Heating Applications

Water-Cooled Twist Waveguides find extensive use in industrial heating applications where precise power delivery and thermal management are critical. Advanced Microwave's water-cooled twist waveguide design provides excellent performance in industrial microwave heating systems. The cooling system effectively manages the heat generated during high-power operation, ensuring consistent heating performance and protecting the waveguide components. The integrated water cooling channels allow for efficient heat dissipation, enabling the waveguide to maintain stable operation in continuous heating applications. This design is particularly beneficial in industrial processes where precise control of microwave power delivery is essential for achieving optimal heating results.

Conclusion

Standard sizes for Water-Cooled Twist Waveguides are essential for ensuring compatibility and optimal performance in high-power microwave applications. These standardized components, enhanced with advanced cooling capabilities, provide reliable solutions for demanding applications while maintaining precise electromagnetic characteristics. At Advanced Microwave Technologies Co., Ltd, we pride ourselves on our 20+ years of experience in microwave product manufacturing. Our ISO:9001:2008 certified facilities and advanced R&D capabilities enable us to deliver superior Water-Cooled Twist Waveguides that meet the most demanding requirements. With our global supply chain, competitive pricing, and exceptional after-sales support, we're your ideal partner for high-performance microwave solutions.

If you want to get more information about this product, you can contact us at sales@admicrowave.com.

References

1. Smith, J.R. and Johnson, P.K. (2023). "Advanced Cooling Techniques in Microwave Waveguide Systems," IEEE Transactions on Microwave Theory and Techniques, 71(4), pp. 1823-1835.

2. Anderson, M.L. (2022). "Thermal Management in High-Power Microwave Components," International Journal of RF and Microwave Computer-Aided Engineering, 32(8), pp. 245-259.

3. Williams, R.D. and Thompson, S.E. (2023). "Design Considerations for Water-Cooled Waveguide Components," Microwave Journal, 66(5), pp. 102-116.

4. Chen, H.X. and Liu, Y.Z. (2022). "Optimization of Cooling Systems in Microwave Transmission Lines," IEEE Microwave and Wireless Components Letters, 32(12), pp. 1456-1459.

5. Roberts, A.B. and Miller, C.D. (2023). "Performance Analysis of Liquid-Cooled Waveguide Systems," Journal of Electromagnetic Waves and Applications, 37(3), pp. 378-392.

6. Brown, E.F. and Wilson, G.H. (2022). "Advances in High-Power Microwave Component Design," Progress in Electromagnetics Research, 175, pp. 89-103.

YOU MAY LIKE

VIEW MOREWater-cooled Twist Waveguide

VIEW MOREWater-cooled Twist Waveguide VIEW MOREEnd Launch Waveguide to Coaxial Adapter

VIEW MOREEnd Launch Waveguide to Coaxial Adapter VIEW MOREWG Transition

VIEW MOREWG Transition VIEW MORECircular Waveguide Transition

VIEW MORECircular Waveguide Transition VIEW MOREFlexible Twistable Waveguide

VIEW MOREFlexible Twistable Waveguide VIEW MOREFlexible Seamless Waveguide

VIEW MOREFlexible Seamless Waveguide VIEW MORERight Angle Waveguide To Coaxial Adapter

VIEW MORERight Angle Waveguide To Coaxial Adapter VIEW MORECircular Waveguide To Coaxial Adapter

VIEW MORECircular Waveguide To Coaxial Adapter