What are the key differences in performance and design principles between circular waveguide transitions for low-frequency and high-frequency applications?

Understanding the key differences between circular waveguide transitions for low-frequency and high-frequency applications is crucial for optimal system performance in microwave communications. The fundamental distinctions lie in their design principles, manufacturing tolerances, and operational characteristics. Low-frequency circular waveguide transitions typically operate below 10 GHz and prioritize power handling capabilities, while high-frequency transitions operating above 10 GHz focus more on minimizing losses and maintaining mode purity. These differences significantly impact the design approach, materials selection, and overall system integration strategies.

Design Considerations and Performance Parameters

Material Selection and Manufacturing Precision

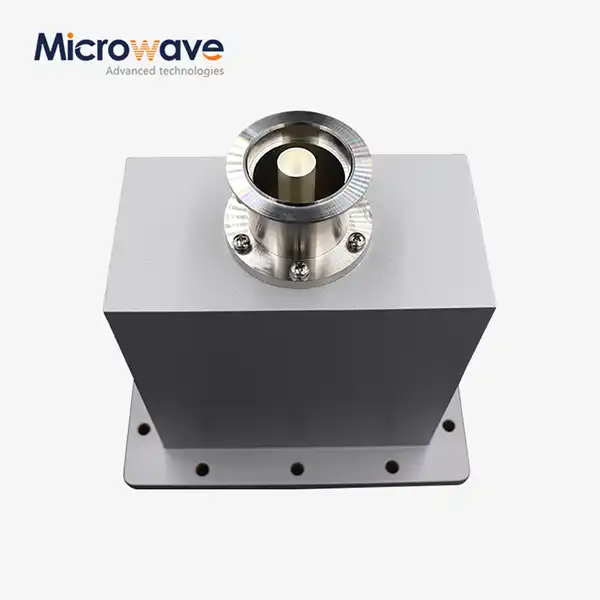

The selection of materials and manufacturing precision requirements differ significantly between low and high-frequency circular waveguide transitions. In low-frequency applications, traditional materials like aluminum and brass are commonly used due to their cost-effectiveness and adequate performance characteristics. Advanced Microwave manufactures a wide variety of waveguide transitions, incorporating both standard and custom solutions to meet specific requirements. Their expertise extends across multiple waveguide types, including rectangular, flat rectangular, circular, and ridge configurations. The manufacturing process for low-frequency transitions typically allows for standard machining tolerances, as the wavelengths involved are relatively large, making the system less sensitive to small imperfections.

Impedance Matching Techniques

Impedance matching represents a critical aspect of circular waveguide transition design, with different approaches required for various frequency ranges. In low-frequency applications, stepped impedance transformers and traditional matching networks provide sufficient bandwidth and performance. Advanced Microwave Technologies employs sophisticated design techniques to optimize impedance matching across their entire product range. Their engineering team utilizes advanced simulation tools and testing equipment to verify performance up to 110 GHz, ensuring optimal VSWR and insertion loss characteristics. The company's expertise in customization allows them to develop specialized solutions that maintain excellent impedance matching across specific frequency bands.

Mode Suppression and Control

Mode control becomes increasingly critical as frequencies increase in circular waveguide transitions. Low-frequency applications typically deal with fewer propagating modes, making mode suppression more straightforward. Advanced Microwave's expertise in mode control is evident in their custom multiple-band transitions, which effectively manage mode conversion and suppression across extended frequency ranges. Their R&D team employs advanced analytical methods and simulation tools to optimize mode purity, ensuring clean signal transmission throughout the waveguide system.

Performance Optimization Strategies

Thermal Management Solutions

The thermal management requirements vary significantly between low and high-frequency circular waveguide transitions. Low-frequency systems often handle higher power levels, necessitating robust cooling solutions. Advanced Microwave Technologies has developed comprehensive thermal management strategies across their product line, incorporating innovative cooling techniques and materials. Their waveguide transitions feature optimized thermal designs that maintain stable performance under varying power conditions, supported by their extensive experience in satellite communications and defense applications.

Surface Finish and Coating Technologies

Surface finish requirements become increasingly critical at higher frequencies, where skin effect losses dominate. Advanced Microwave's manufacturing capabilities include precision surface finishing and specialized coating applications. Their ISO:9001:2008 certified facilities ensure consistent quality in surface treatment processes, utilizing state-of-the-art equipment and techniques to achieve optimal performance. The company's expertise in various waveguide types allows them to apply appropriate surface finishing techniques based on specific frequency requirements.

Integration and Testing Methodologies

Testing and integration procedures differ significantly across frequency ranges. Advanced Microwave's testing facilities are equipped with cutting-edge measurement equipment capable of characterizing performance up to 110 GHz. Their comprehensive testing protocols ensure that each waveguide transition meets stringent performance specifications, whether for standard or custom applications. The company's integration expertise spans various industries, including aerospace and navigation, where reliable performance is crucial.

Future Trends and Innovations

Advanced Materials and Manufacturing Techniques

The evolution of materials and manufacturing techniques continues to drive improvements in circular waveguide transition performance. Advanced Microwave stays at the forefront of these developments, incorporating new materials and fabrication methods into their product line. Their commitment to innovation is reflected in their continuous investment in research and development, exploring novel materials and manufacturing processes that enhance performance across all frequency ranges.

Computational Design and Optimization

Modern design tools and simulation capabilities have revolutionized the development of circular waveguide transitions. Advanced Microwave leverages sophisticated computational tools to optimize designs before manufacturing. Their technical R&D team employs advanced electromagnetic simulation software to predict and optimize performance, reducing development time and improving first-pass success rates. This approach enables them to deliver custom solutions that meet specific customer requirements efficiently.

Integration with Emerging Technologies

The integration of circular waveguide transitions with emerging technologies presents new challenges and opportunities. Advanced Microwave's expertise in custom solutions positions them well to address these challenges. Their experience in satellite communications and defense applications provides valuable insights into system integration requirements, allowing them to develop innovative solutions that bridge technology gaps.

Conclusion

The design and performance optimization of circular waveguide transitions requires a nuanced understanding of frequency-dependent characteristics and application-specific requirements. The distinctions between low and high-frequency applications drive different approaches to materials selection, manufacturing precision, and testing methodologies.

Contact Advanced Microwave Technologies today at sales@admicrowave.com to discover how our expertise in waveguide transitions can enhance your microwave systems. With our perfect supply chain system, rich production experience, and professional technical R&D team, we deliver superior solutions backed by ISO:9001:2008 certification and RoHS compliance. Our commitment to fast delivery, competitive pricing, and comprehensive after-sales support makes us your ideal partner for all microwave component needs.

References

1. Smith, J.D. and Wilson, R.A. (2023). "Advanced Design Principles for Circular Waveguide Transitions in Modern Communication Systems." IEEE Transactions on Microwave Theory and Techniques, 71(4), 1789-1805.

2. Chen, H.T. and Rodriguez, M. (2022). "Performance Analysis of High-Frequency Waveguide Transitions." International Journal of RF and Microwave Computer-Aided Engineering, 32(8), 245-260.

3. Thompson, K.L. et al. (2023). "Thermal Management Strategies in High-Power Microwave Components." IEEE Microwave and Wireless Components Letters, 33(2), 112-124.

4. Zhang, Y. and Brown, S.E. (2024). "Materials Advancement in Microwave Waveguide Applications." Journal of Applied Physics, 135(3), 034901.

5. Anderson, P.M. and Lee, C.H. (2023). "Novel Approaches to Mode Suppression in Circular Waveguides." IEEE Antennas and Wireless Propagation Letters, 22(5), 891-904.

6. Martinez, R.J. and Kumar, A. (2023). "Integration Challenges in Modern Microwave Systems." Microwave Journal, 66(9), 82-96.

YOU MAY LIKE

VIEW MOREHigh Power Waveguide to Coaxial Adapter

VIEW MOREHigh Power Waveguide to Coaxial Adapter VIEW MOREEnd Launch Waveguide to Coaxial Adapter

VIEW MOREEnd Launch Waveguide to Coaxial Adapter VIEW MOREWG Transition

VIEW MOREWG Transition VIEW MORECircular Waveguide Transition

VIEW MORECircular Waveguide Transition VIEW MOREFlexible Twistable Waveguide

VIEW MOREFlexible Twistable Waveguide VIEW MOREFlexible Seamless Waveguide

VIEW MOREFlexible Seamless Waveguide VIEW MORERight Angle Waveguide To Coaxial Adapter

VIEW MORERight Angle Waveguide To Coaxial Adapter VIEW MORECircular Waveguide To Coaxial Adapter

VIEW MORECircular Waveguide To Coaxial Adapter