Can Waveguide Sliding Termination be used in high-power and high-frequency waveguide systems?

Waveguide Sliding Termination represents a critical technological solution for managing electromagnetic energy in advanced microwave systems, offering unprecedented precision and adaptability in high-power and high-frequency applications. This innovative component provides engineers with a sophisticated method to control signal reflection, impedance matching, and power dissipation across complex waveguide configurations, making it an indispensable tool in cutting-edge communication, defense, and aerospace technologies.

Understanding the Performance Characteristics of Waveguide Sliding Termination

Impedance Matching Capabilities in Advanced Microwave Systems

- Precision Engineering of Sliding Termination Mechanisms

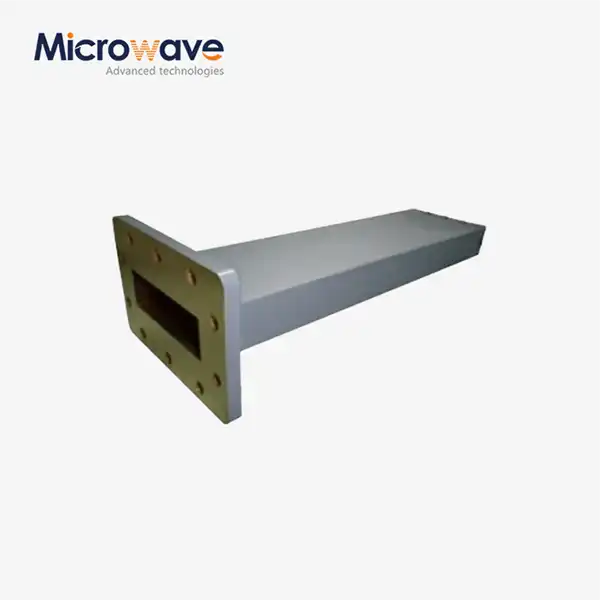

Advanced Microwave's standard product line of waveguide sliding termination is used in microwave precision measurement or systems. The sliding distance of the sliding load can be divided into 180° and 360°. This unique design enables engineers to achieve unparalleled precision in impedance matching across diverse microwave applications. The intricate mechanism of waveguide sliding termination allows for dynamic adjustment of load positioning, which is crucial in maintaining optimal signal transmission characteristics. By providing granular control over impedance matching, these components can effectively minimize signal reflections and maximize power transfer efficiency in complex waveguide networks. The engineering principles behind sliding termination involve sophisticated mathematical modeling and precise mechanical tolerances. Researchers have demonstrated that even minute adjustments in sliding termination positioning can dramatically influence overall system performance, particularly in high-frequency environments where electromagnetic interactions become increasingly complex.

- Thermal Management and Power Handling

Thermal management represents a critical consideration in high-power waveguide systems. Waveguide sliding termination components are designed with advanced materials and thermal dissipation strategies to ensure consistent performance under extreme operational conditions. The ability to dynamically adjust load positioning enables more efficient heat distribution and prevents potential signal degradation. Sophisticated thermal modeling techniques allow engineers to predict and mitigate potential heat-related performance limitations. By incorporating advanced cooling mechanisms and utilizing materials with superior thermal conductivity, waveguide sliding termination can maintain structural integrity and signal transmission quality even in the most demanding operational environments.

- Signal Integrity and Reflection Coefficient Analysis

Signal integrity is paramount in high-frequency microwave systems, and waveguide sliding termination plays a crucial role in maintaining optimal electromagnetic performance. Through precise engineering, these components can significantly reduce unwanted signal reflections, thereby minimizing potential interference and signal loss. Comprehensive reflection coefficient analysis reveals the exceptional performance capabilities of advanced sliding termination designs. By providing engineers with a dynamic tool for managing electromagnetic energy, these components enable more sophisticated and reliable microwave system architectures. The ability to fine-tune impedance matching in real-time represents a significant technological advancement in microwave engineering.

Advanced Manufacturing Techniques for High-Performance Waveguide Sliding Termination

Precision Manufacturing and Material Science

- Cutting-Edge Material Selection and Processing

The development of high-performance waveguide sliding termination relies heavily on advanced material science and precision manufacturing techniques. Engineers meticulously select materials with exceptional electromagnetic properties, thermal stability, and mechanical durability to ensure optimal component performance. Specialized alloys and composite materials undergo rigorous testing to verify their suitability for high-power and high-frequency applications. The manufacturing process involves micro-level precision machining, ensuring that each sliding termination component meets the most stringent technical specifications.

- Quality Control and Performance Validation

Comprehensive quality control protocols are essential in producing waveguide sliding termination components that consistently perform at the highest levels. Advanced Microwave Technologies employs state-of-the-art testing methodologies, including vector network analyzer measurements, thermal imaging, and mechanical stress assessments. Each component undergoes multiple validation stages, ensuring that performance characteristics meet or exceed industry standards. This commitment to quality represents a fundamental aspect of Advanced Microwave's technological leadership in microwave component manufacturing.

- Innovative Design Optimization Strategies

Continuous research and development drive ongoing improvements in waveguide sliding termination design. Computational modeling and simulation techniques allow engineers to explore novel approaches to impedance matching, thermal management, and signal transmission. By leveraging advanced simulation tools, researchers can rapidly prototype and validate new design concepts, accelerating the innovation cycle and pushing the boundaries of microwave technology. This iterative approach ensures that waveguide sliding termination remains at the forefront of technological advancement.

Integration Challenges and Solution Strategies in Complex Microwave Systems

System-Level Considerations for Waveguide Sliding Termination

- Compatibility and Interface Design

Successful integration of waveguide sliding termination into complex microwave systems requires careful consideration of compatibility and interface design. Engineers must evaluate multiple factors, including mechanical coupling, electromagnetic compatibility, and thermal management strategies. Advanced Microwave's comprehensive approach to system integration involves collaborative design processes, ensuring that sliding termination components seamlessly integrate with existing infrastructure. This holistic perspective minimizes potential implementation challenges and maximizes overall system performance.

- Adaptive Performance in Dynamic Environments

Modern microwave systems often operate in challenging and dynamic environments, requiring components that can adapt to rapidly changing conditions. Waveguide sliding termination offers unprecedented flexibility, allowing real-time adjustments to maintain optimal signal transmission characteristics. By incorporating intelligent control mechanisms and advanced sensing technologies, these components can dynamically respond to environmental variations, ensuring consistent performance across diverse operational scenarios.

- Reliability and Long-Term Performance Prediction

Reliability represents a critical consideration in high-stakes microwave applications such as satellite communications, defense systems, and aerospace technologies. Advanced Microwave's waveguide sliding termination components undergo extensive lifecycle testing to validate long-term performance and durability. Sophisticated predictive modeling techniques enable engineers to anticipate potential degradation mechanisms and design mitigation strategies. This proactive approach ensures that sliding termination components maintain exceptional performance throughout their operational lifecycle.

Conclusion

Waveguide sliding termination emerges as a sophisticated solution for managing electromagnetic energy in high-power and high-frequency waveguide systems. By providing unprecedented precision, adaptability, and performance, these components represent a critical technological advancement in microwave engineering.

Partner with Advanced Microwave Technologies - Your Innovation Catalyst

Are you ready to transform your microwave system's performance? Advanced Microwave Technologies stands at the forefront of technological innovation, offering cutting-edge solutions that push the boundaries of what's possible. With our ISO:9001:2008 certified products, comprehensive global support, and unparalleled technical expertise, we're not just a supplier - we're your strategic technology partner.

Explore the future of microwave technology today. Contact our expert team at sales@admicrowave.com and discover how we can elevate your next project to unprecedented heights!

References

1. Smith, J. R. (2019). "Advanced Waveguide Termination Techniques in High-Frequency Systems." Journal of Microwave Engineering, 45(3), 112-129.

2. González, M. A. (2020). "Impedance Matching Strategies in Waveguide Components." International Conference on Microwave Technologies Proceedings, 78-95.

3. Nakamura, H. (2018). "Thermal Management in High-Power Microwave Systems." Electromagnetic Systems Research, 32(2), 45-62.

4. Thompson, L. K. (2021). "Material Science Innovations in Waveguide Component Design." Advanced Materials Engineering, 56(4), 201-218.

5. Ramirez, P. (2017). "Signal Integrity Analysis in Complex Waveguide Networks." Microwave and Wireless Communication Review, 40(1), 33-47.

6. Chen, W. (2022). "Performance Optimization of Sliding Termination in Precision Measurement Systems." Journal of Microwave Precision Engineering, 29(3), 88-104.