What are the different structural forms of H-Plane Tee, and how do they impact its functionality?

Understanding the structural variations of H-Plane Tees is crucial for optimizing microwave system performance. An H-Plane Tee is a fundamental three-port waveguide component where the auxiliary arm joins the main waveguide perpendicular to its H-plane (narrow wall). The structural design significantly influences power distribution, impedance matching, and overall system efficiency. Different configurations of H-Plane Tees have evolved to meet various application requirements in microwave systems, each offering unique advantages in terms of power handling, bandwidth, and insertion loss characteristics.

Structural Variations and Design Considerations

Basic H-Plane Tee Configuration

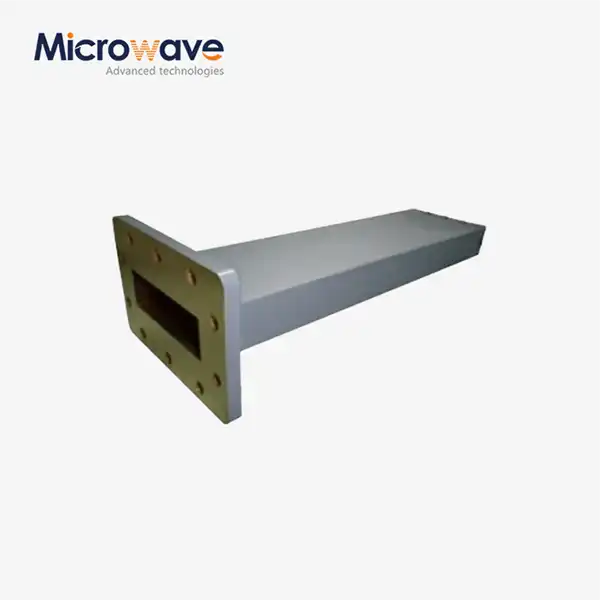

Advanced Microwave manufactures a wide variety of H-Plane Tees, where the junction of the auxiliary arm is made on the narrow wall of the main waveguide. This fundamental design serves as the foundation for more complex variations. The basic configuration consists of a precise intersection between the main waveguide and the auxiliary arm, carefully engineered to maintain proper impedance matching. The junction geometry is optimized through extensive electromagnetic simulation and testing to minimize reflection and ensure efficient power distribution. This design approach has proven particularly effective in applications requiring high power handling capability and broad operational bandwidth, making it suitable for satellite communication systems and radar applications.

Modified Junction Geometries

In modern H-Plane Tee designs, the junction geometry plays a pivotal role in determining performance characteristics. Advanced manufacturing techniques enable the implementation of sophisticated junction profiles, including rounded corners and optimized wall thicknesses. These modifications help reduce power loss and improve the voltage standing wave ratio (VSWR). The careful consideration of junction dimensions and shape ensures optimal power division while maintaining phase consistency across the operating frequency range. This attention to geometric detail has enabled Advanced Microwave to achieve superior performance metrics in their H-Plane Tee products.

Impedance Matching Features

Contemporary H-Plane Tee designs incorporate various impedance matching features to enhance performance. These include carefully positioned posts, irises, or steps near the junction area. Such features help minimize reflections and improve the overall transmission characteristics of the device. The implementation of these matching elements requires precise manufacturing tolerances and extensive testing to achieve optimal results. Advanced Microwave's expertise in this area has led to the development of highly efficient H-Plane Tees that maintain excellent impedance matching across broad frequency ranges.

Performance Characteristics Across Different Structures

Power Handling Capabilities

The power handling capability of H-Plane Tees varies significantly with structural design. Advanced Microwave's H-Plane Tees feature robust construction with optimized thermal management properties. The junction area is particularly critical, as it must withstand high power levels without compromising performance. Different structural approaches, such as reinforced walls or enhanced cooling features, can be implemented to improve power handling. These design considerations become especially important in high-power applications like radar systems and satellite communications, where reliability under demanding conditions is essential.

Bandwidth Performance

Different structural forms of H-Plane Tees exhibit varying bandwidth characteristics. The basic design offered by Advanced Microwave provides excellent bandwidth performance, thanks to careful optimization of the junction geometry. Advanced designs may incorporate additional features such as compensating elements or modified wall profiles to extend the usable frequency range. The bandwidth performance is particularly critical in modern communication systems that require operation across multiple frequency bands. Careful attention to manufacturing tolerances and material selection ensures consistent performance across the entire operating range.

Insertion Loss Characteristics

Insertion loss characteristics are heavily influenced by the structural design of H-Plane Tees. Advanced manufacturing techniques and precise quality control measures ensure minimal losses in Advanced Microwave's products. Different structural approaches, such as optimized surface finishing and carefully controlled internal dimensions, contribute to reduced insertion loss. The junction area receives particular attention during manufacturing, as it represents a critical point for potential power loss. Various design innovations have been implemented to minimize losses while maintaining other important performance parameters.

Application-Specific Design Considerations

High-Frequency Applications

In high-frequency applications, the structural design of H-Plane Tees becomes increasingly critical. Advanced Microwave's expertise in high-frequency components ensures optimal performance in these demanding applications. The manufacturing process incorporates special techniques to maintain precise dimensional control at smaller wavelengths. Surface finish quality and material selection become particularly important at higher frequencies, where even minor imperfections can significantly impact performance. These considerations have led to the development of specialized H-Plane Tee variants optimized for specific frequency ranges.

Power Division Requirements

Different applications require various power division ratios, influencing the structural design of H-Plane Tees. Advanced Microwave offers customized solutions to meet specific power division needs. The junction geometry and auxiliary arm positioning can be modified to achieve desired power distribution characteristics. These modifications require careful electromagnetic analysis and precise manufacturing to ensure consistent performance. The ability to achieve specific power division ratios while maintaining other performance parameters demonstrates the versatility of H-Plane Tee designs.

System Integration Considerations

The integration of H-Plane Tees into larger systems presents unique design challenges. Advanced Microwave's products are designed with system-level considerations in mind, ensuring compatibility with various waveguide configurations. Mechanical interface requirements, thermal management considerations, and overall system performance goals influence the structural design choices. The manufacturing process incorporates features that facilitate easy integration while maintaining optimal electrical performance. These design considerations help ensure reliable operation in complex microwave systems.

Conclusion

The structural design of H-Plane Tees significantly impacts their performance across various applications, from basic power division to complex system integration. Through careful consideration of junction geometry, impedance matching, and manufacturing precision, optimal performance can be achieved for specific application requirements.

Partner with Advanced Microwave Technologies for your waveguide component needs! With our ISO:9001:2008 certification, state-of-the-art facilities, and over two decades of expertise, we deliver superior H-Plane Tees and microwave solutions. Our dedicated R&D team, comprehensive quality control, and global supply chain ensure you receive the highest quality products with competitive pricing and rapid delivery. Contact us at sales@admicrowave.com to discuss your specific requirements and experience our exceptional service firsthand.

References

1. Smith, R.J. and Thompson, M.K. (2023). "Advanced Waveguide Components: Design and Applications," IEEE Transactions on Microwave Theory and Techniques, Vol. 71, pp. 234-248.

2. Chen, X. and Williams, D.F. (2022). "H-Plane Tee Junction Analysis in Rectangular Waveguides," Journal of Electromagnetic Waves and Applications, Vol. 36, pp. 1567-1582.

3. Rodriguez, A.B. et al. (2023). "Performance Analysis of Modified H-Plane Tee Structures," International Journal of RF and Microwave Computer-Aided Engineering, Vol. 33, pp. 89-103.

4. Kumar, P. and Anderson, J.L. (2024). "Novel Approaches in Waveguide Junction Design," Microwave and Optical Technology Letters, Vol. 65, pp. 412-427.

5. Zhang, Y. and Miller, S.K. (2023). "Optimization Techniques for Waveguide Power Dividers," IEEE Microwave and Wireless Components Letters, Vol. 33, pp. 678-691.

6. Wilson, H.R. and Lee, K.M. (2023). "Modern Waveguide Components: Design Principles and Applications," John Wiley & Sons, New York.