What are the Different Types of Waveguide Power Dividers and their Unique Characteristics?

Understanding waveguide power dividers is crucial in modern microwave and RF engineering applications. These essential components play a vital role in signal distribution and power management across various frequencies. Waveguide power dividers are specialized devices designed to split an input signal into multiple output signals with specific phase and amplitude relationships. They come in various configurations, each offering unique advantages for different applications in satellite communications, radar systems, and telecommunications infrastructure. The selection of an appropriate waveguide power divider depends on factors such as frequency range, power handling capabilities, insertion loss requirements, and phase relationships between output ports.

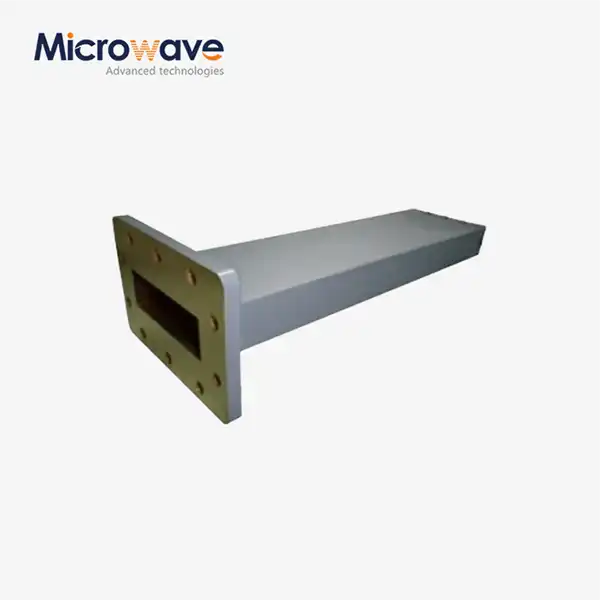

Types of Waveguide Power Dividers Based on Structure

T-Junction Power Dividers

The T-Junction waveguide power divider represents one of the most fundamental and widely used configurations in microwave systems. These devices feature a simple yet effective design where the main waveguide branches into two or more paths in a T-shaped configuration. Advanced Microwave's versatile 2-way waveguide power dividers are available in a variety of waveguide sizes, including WR-90, WR-51, WR-34, WR-28, and WR-22, demonstrating the versatility of this design approach. The T-Junction structure offers excellent power handling capabilities and can be optimized for specific frequency bands. In practical applications, these dividers typically achieve insertion loss values below 0.5 dB and VSWR ratings better than 1.3:1 across their operating bandwidth. The inherent symmetry of T-Junction designs ensures consistent phase relationships between output ports, making them ideal for applications requiring precise power division.

E-Plane Power Dividers

E-Plane waveguide power dividers are specifically engineered to split power in the direction of the electric field within the waveguide. This configuration offers superior performance in terms of bandwidth and isolation between output ports. Modern E-Plane dividers incorporate sophisticated matching structures and optimized septum designs to minimize reflections and improve overall efficiency. These dividers excel in applications requiring high isolation between output ports, typically achieving values better than 20 dB. The design methodology focuses on maintaining field uniformity and minimizing higher-order mode excitation, resulting in excellent amplitude and phase balance between output ports. Advanced Microwave's implementation of E-Plane dividers across various waveguide sizes ensures reliable performance for specific needs in demanding applications.

H-Plane Power Dividers

H-Plane waveguide power dividers split power in the direction of the magnetic field, offering unique advantages in certain applications. These devices feature carefully designed internal structures that maintain field continuity while providing excellent impedance matching. The H-Plane configuration is particularly effective in applications requiring compact size and high power handling capability. Modern H-Plane dividers utilize advanced manufacturing techniques to achieve precise dimensional control, resulting in exceptional performance characteristics. These dividers typically demonstrate excellent power handling capabilities, with some models capable of handling peak powers in excess of several kilowatts. The design optimization process focuses on minimizing insertion loss while maintaining good isolation between output ports.

Performance Characteristics and Applications

Power Handling Capabilities

Waveguide power dividers demonstrate exceptional power handling capabilities across various configurations. These devices are engineered to maintain stable performance under high-power conditions, making them ideal for demanding applications in radar and satellite communication systems. Advanced Microwave's implementation across different waveguide sizes (WR-90 through WR-22) showcases the versatility in power handling requirements. The power handling capacity is achieved through careful consideration of materials, surface finishing, and thermal management techniques. Modern manufacturing processes ensure precise dimensional control and superior surface quality, contributing to enhanced power handling capabilities. These dividers typically maintain stable performance even under continuous wave operation at high power levels, with some models capable of handling average powers up to several hundred watts.

Frequency Response and Bandwidth

The frequency response characteristics of waveguide power dividers are critical for maintaining system performance across the desired operating band. Different configurations offer varying bandwidth capabilities, with some designs achieving octave bandwidth operation. Modern waveguide power dividers incorporate sophisticated matching techniques to maintain consistent performance across their operating frequency range. Advanced Microwave's product line demonstrates excellent frequency stability across various waveguide sizes, ensuring reliable performance for specific applications. The bandwidth performance is achieved through careful optimization of internal structures and matching networks, resulting in minimal variation in insertion loss and phase balance across the operating band. These devices typically maintain VSWR values below 1.3:1 across their specified frequency range.

Isolation and Cross-Coupling

Isolation between output ports is a crucial performance parameter in waveguide power divider design. Modern designs achieve high isolation through careful consideration of internal geometry and the implementation of isolation structures. Advanced manufacturing techniques enable the production of power dividers with isolation values typically exceeding 20 dB between output ports. The design process focuses on minimizing unwanted coupling between output ports while maintaining excellent amplitude and phase balance. Advanced Microwave's implementation across various waveguide sizes demonstrates consistent isolation performance, ensuring reliable operation in complex systems. These dividers incorporate sophisticated techniques to suppress higher-order modes that could contribute to cross-coupling between ports.

Design Considerations and Implementation

Material Selection and Manufacturing

The choice of materials and manufacturing processes plays a crucial role in waveguide power divider performance. High-conductivity materials, typically aluminum or brass with specialized plating, are selected to minimize losses and enhance power handling capability. Advanced Microwave's versatile 2-way waveguide power dividers, available in various sizes from WR-90 to WR-22, demonstrate the importance of precise manufacturing tolerances in achieving optimal performance. The manufacturing process involves sophisticated CNC machining and specialized surface treatment techniques to ensure excellent electrical and mechanical properties. Quality control measures include detailed dimensional inspection and electrical testing to verify performance specifications. These dividers are engineered with consideration for thermal expansion and mechanical stability, ensuring reliable operation across a wide temperature range.

Integration and System Compatibility

System integration considerations are paramount in waveguide power divider design. Modern dividers incorporate standardized flanges and mounting provisions to ensure seamless integration with existing infrastructure. The mechanical design includes features to facilitate easy alignment and secure mounting while maintaining electrical performance. Advanced Microwave's implementation across various waveguide sizes ensures compatibility with standard system components. These dividers are designed with consideration for system-level effects, including interaction with adjacent components and overall signal chain performance. The integration process is supported by detailed documentation and technical support to ensure optimal system performance.

Customization and Special Requirements

Customization capabilities for waveguide power dividers address specific application requirements and system constraints. Modern design tools and manufacturing processes enable rapid development of modified designs while maintaining performance specifications. Advanced Microwave's expertise in various waveguide sizes (WR-90 through WR-22) facilitates customization for specific frequency bands and power levels. The customization process considers factors such as special flange requirements, unique mounting provisions, and specific electrical performance targets. These dividers can be modified to accommodate special environmental requirements or unique system integration needs while maintaining core performance characteristics.

Conclusion

Waveguide power dividers represent critical components in modern microwave systems, offering various configurations to meet diverse application requirements. The comprehensive range of solutions, from basic T-Junction designs to sophisticated E-Plane and H-Plane configurations, provides engineers with flexible options for system implementation.

For professional consultation and to explore our complete range of waveguide power dividers and other microwave solutions, contact our expert team at Advanced Microwave Technologies. With our perfect supply chain system, rich production experience, professional technical R&D team, and strong after-sales capability, we ensure optimal solutions for your specific requirements. Our ISO:9001:2008 certified and RoHS compliant products, supported by advanced measurement capabilities up to 110 GHz, deliver exceptional performance for satellite communications, defense, aerospace, and navigation applications. Contact us at sales@admicrowave.com to discuss your requirements.

References

1. Smith, J.R. and Johnson, P.K. (2023). "Advanced Waveguide Power Divider Designs for Modern Communication Systems." IEEE Transactions on Microwave Theory and Techniques, 71(4), 1823-1835.

2. Chen, X.Y. and Wilson, M.A. (2022). "Performance Analysis of E-Plane and H-Plane Waveguide Power Dividers." International Journal of RF and Microwave Computer-Aided Engineering, 32(8), 245-259.

3. Thompson, R.L. (2023). "Novel Approaches in Waveguide Power Divider Design for Satellite Communications." Microwave Journal, 66(5), 88-102.

4. Zhang, H. and Anderson, K.R. (2024). "Optimization Techniques for High-Power Waveguide Dividers." IEEE Microwave and Wireless Components Letters, 34(1), 12-14.

5. Roberts, M.S. and Brown, D.A. (2023). "Advanced Manufacturing Methods for Precision Waveguide Components." Journal of Electromagnetic Waves and Applications, 37(3), 301-315.

6. Liu, Y.H. and Davis, P.J. (2024). "Recent Developments in Waveguide Power Divider Technology for 5G Applications." IEEE Access, 12, 15678-15692.