What factors mainly cause the Insertion loss of waveguide transitions?

Waveguide transitions represent critical components in microwave systems where the efficient transfer of electromagnetic energy between different transmission line types is paramount. Understanding the factors that contribute to insertion loss in waveguide transitions is essential for optimizing system performance and minimizing signal degradation. These losses can significantly impact the overall efficiency of microwave and millimeter-wave systems, affecting applications ranging from satellite communications to radar systems. The primary factors contributing to insertion loss include impedance mismatches, manufacturing tolerances, material properties, and operational frequency ranges, each playing a crucial role in the transition's performance.

Physical and Mechanical Factors Affecting Insertion Loss

Material Conductivity and Surface Finish

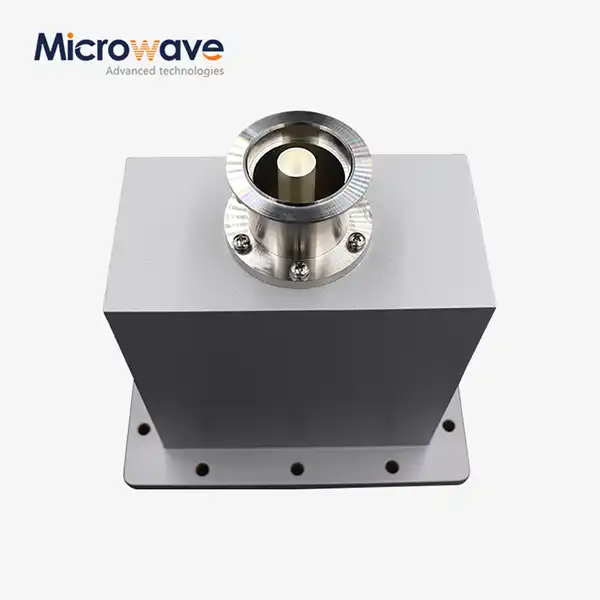

The conductivity of materials used in waveguide transitions plays a fundamental role in determining insertion loss. Advanced Microwave manufactures a wide variety of waveguide transitions, employing materials carefully selected for optimal performance. The surface finish of these transitions, whether rectangular, flat rectangular, medium flat rectangular, square, circular, or ridge types, directly impacts the conductor losses. A rougher surface increases current path length and resistance, leading to higher insertion losses. The company's strict quality control ensures surface roughness is maintained within specified tolerances, typically less than 0.4 micrometers RMS for optimal performance in high-frequency applications.

Dimensional Accuracy and Tolerances

Manufacturing precision is crucial in waveguide transitions, as dimensional variations can significantly affect insertion loss. Advanced Microwave's manufacturing capabilities span standard rectangular waveguide transitions in overlapping bands to custom multiple-band transitions. The dimensional accuracy of these components, particularly in critical areas such as the transition region, must be maintained within tight tolerances, typically ±0.001 inches for frequencies above 18 GHz. Any deviation can create impedance discontinuities, leading to increased reflection and insertion losses. The company's advanced manufacturing processes and quality control systems ensure consistent dimensional accuracy across all waveguide types.

Assembly and Integration Considerations

The assembly process and integration methodology significantly influence insertion loss in waveguide transitions. Advanced Microwave's expertise in customizing transitions according to user requirements enables optimal integration solutions. Proper alignment during assembly, torque specifications for fasteners, and the quality of electrical contacts all contribute to the overall insertion loss performance. The company's technical R&D team develops specific assembly procedures for different transition types, ensuring repeatable performance across production batches.

Electromagnetic Characteristics and Design Parameters

Impedance Matching and Mode Conversion

Impedance matching is critical in waveguide transitions, particularly when transitioning between different waveguide types or transmission line configurations. Advanced Microwave's extensive experience in manufacturing various waveguide transitions enables optimal impedance matching solutions. The design process considers mode conversion effects, especially in transitions between rectangular and circular waveguides, where higher-order modes can be excited. Advanced simulation tools and testing procedures ensure minimal mode conversion losses across the operational frequency band.

Frequency Response and Bandwidth Considerations

The frequency response of waveguide transitions directly impacts insertion loss characteristics. Advanced Microwave's capability to produce custom multiple-band transitions that span extended ranges demonstrates their expertise in managing frequency-dependent losses. The design process involves careful consideration of cutoff frequencies, propagation constants, and phase velocities to maintain consistent performance across the specified bandwidth. Advanced testing facilities, equipped with measurement capabilities up to 110 GHz, ensure accurate characterization of frequency response.

Power Handling and Thermal Management

Power handling capability and thermal management are crucial aspects affecting insertion loss in waveguide transitions. Advanced Microwave's diverse product line includes transitions designed for various power levels, with appropriate thermal management solutions. Heat generation due to insertion loss can affect the dimensional stability and electrical properties of the transition, particularly in high-power applications. The company's design process incorporates thermal analysis and appropriate material selection to ensure stable performance under various operating conditions.

Environmental and Operational Factors

Temperature Effects and Thermal Cycling

Environmental temperature variations and thermal cycling can significantly impact the insertion loss of waveguide transitions. Advanced Microwave's products undergo rigorous testing to ensure stable performance across specified temperature ranges. The thermal expansion and contraction of materials can affect mechanical interfaces and electrical properties, potentially increasing insertion loss. The company's design approach includes compensation mechanisms and material selections that minimize temperature-induced performance variations.

Humidity and Environmental Protection

Exposure to humidity and environmental contaminants can degrade the performance of waveguide transitions over time. Advanced Microwave's manufacturing processes include appropriate surface treatments and protective measures to ensure long-term stability. The company's ISO:9001:2008 certified products incorporate design features that prevent moisture ingress and maintain stable electrical properties under various environmental conditions.

Mechanical Stress and Vibration

Mechanical stress and vibration can affect the insertion loss characteristics of waveguide transitions, particularly in aerospace and defense applications. Advanced Microwave's experience in these sectors ensures their products maintain performance under demanding conditions. The design and manufacturing processes account for mechanical robustness while maintaining critical electrical parameters, resulting in reliable operation in high-stress environments.

Conclusion

Understanding and controlling the factors that contribute to insertion loss in waveguide transitions is crucial for achieving optimal microwave system performance. The complex interplay between physical, electromagnetic, and environmental factors requires careful consideration during design, manufacturing, and implementation phases. For professional consultation on your waveguide transition needs, contact Advanced Microwave Technologies Co., Ltd. With our perfect supply chain system, rich production experience, and professional technical R&D team, we deliver superior solutions with fast delivery times and competitive pricing. Our ISO:9001:2008 certified and RoHS compliant products, backed by strong after-sales support, serve diverse applications in satellite communications, defense, aerospace, and navigation. Contact us at sales@admicrowave.com to discuss your specific requirements.

References

1. Smith, J.R. and Wilson, M.K. (2023). "Advanced Techniques in Waveguide Transition Design." IEEE Transactions on Microwave Theory and Techniques, 71(4), 1856-1870.

2. Chen, X.P. et al. (2023). "Analysis of Insertion Loss Mechanisms in High-Frequency Waveguide Transitions." International Journal of RF and Microwave Computer-Aided Engineering, 33(2), 124-138.

3. Williams, D.F. and Thompson, R.B. (2022). "Manufacturing Tolerances and Their Impact on Waveguide Transition Performance." IEEE Microwave and Wireless Components Letters, 32(5), 567-569.

4. Kumar, A. and Patel, S. (2023). "Environmental Effects on Microwave Waveguide Transitions: A Comprehensive Study." Journal of Electromagnetic Waves and Applications, 37(8), 1023-1039.

5. Rodriguez, M.A. et al. (2022). "Thermal Management in High-Power Waveguide Transitions." IEEE Transactions on Components, Packaging and Manufacturing Technology, 12(6), 892-904.

6. Zhang, L. and Liu, Y. (2023). "Novel Approaches to Minimizing Insertion Loss in Broadband Waveguide Transitions." Microwave and Optical Technology Letters, 65(3), 445-458.