What is the manufacturing process of flexible twistable waveguide?

The manufacturing process of flexible twistable waveguide represents a sophisticated blend of precision engineering and advanced materials science. This critical component in microwave and RF systems requires meticulous attention to detail throughout its production stages to ensure optimal performance and reliability. The process involves specialized techniques for creating flexible waveguide sections that can both bend and twist while maintaining consistent electrical properties and mechanical integrity. Understanding this manufacturing process is essential for engineers and technical professionals working in satellite communications, defense systems, and aerospace applications.

Manufacturing Process Fundamentals

Raw Material Selection and Preparation

The manufacturing of flexible twistable waveguide begins with careful material selection, a critical phase that determines the final product's performance characteristics. Advanced Microwave Technologies employs premium-grade materials, including high-conductivity copper or aluminum for the inner conducting surface, and specialized flexible materials for the outer structure. The process involves preparing these materials through precise cleaning, treatment, and quality inspection procedures. The company's commitment to excellence is evident in their flexible line of rectangular twistable waveguides, which are specifically engineered for applications demanding both bending and twisting capabilities. The materials undergo rigorous testing to ensure they meet stringent specifications for flexibility, conductivity, and durability, particularly important for maintaining consistent electrical properties throughout the waveguide's intended range of motion.

Forming and Shaping Techniques

The core manufacturing process involves sophisticated forming techniques that transform raw materials into the distinctive flexible twistable waveguide structure. Advanced Microwave's manufacturing expertise allows them to create precise geometries while maintaining the critical internal dimensions that affect microwave propagation. The process includes specialized tooling and forming equipment that carefully shapes the waveguide while preserving its electrical characteristics. This stage requires extensive experience and precision, as even minor variations can significantly impact performance. The company's ability to customize lengths according to customer requirements demonstrates their mastery of these forming techniques, enabling them to produce both standard and custom configurations while maintaining consistent quality across all products.

Surface Treatment and Coating Application

The surface treatment phase is crucial for ensuring optimal electrical performance and environmental protection. Advanced Microwave Technologies implements a comprehensive surface preparation and coating process that includes multiple stages of cleaning, treatment, and protective layer application. The standard model includes a Neoprene jacket application, which serves the dual purpose of pressure retention and environmental protection. This specialized coating process requires precise control of temperature, humidity, and application parameters to achieve the desired results. The company's expertise in surface treatment ensures that each flexible twistable waveguide maintains its performance characteristics while providing excellent durability and reliability in challenging operating conditions.

Quality Control and Testing Procedures

Dimensional Verification Methods

In the quality control process for flexible twistable waveguide manufacturing, Advanced Microwave Technologies employs sophisticated dimensional verification methods to ensure precise compliance with specifications. Their state-of-the-art laboratories, equipped with advanced microwave measurement equipment capable of testing up to 110 GHz, enable comprehensive dimensional analysis. Each waveguide undergoes detailed measurements at multiple points along its length, with particular attention paid to critical dimensions that affect electromagnetic wave propagation. The company's flexible line of rectangular twistable waveguides undergoes rigorous inspection to verify that both the bending and twisting capabilities meet design specifications while maintaining consistent internal dimensions throughout the range of motion.

Electrical Performance Testing

The electrical performance testing phase represents a critical step in ensuring the functionality of each flexible twistable waveguide. Advanced Microwave Technologies conducts comprehensive RF testing using advanced network analyzers and specialized test fixtures. This includes measuring insertion loss, VSWR, phase stability during flexing, and power handling capabilities. The testing procedures verify that the waveguides maintain their electrical characteristics even when subjected to various bending and twisting configurations. The company's ability to produce double-ridged soft waveguides demonstrates their expertise in manufacturing complex configurations while maintaining stringent electrical performance standards across their entire product range.

Environmental and Mechanical Testing

Environmental and mechanical testing ensures the durability and reliability of flexible twistable waveguides under various operating conditions. Advanced Microwave Technologies subjects their products to extensive environmental testing, including temperature cycling, humidity exposure, and pressure testing of the Neoprene jacket. Mechanical testing involves repeated flexing and twisting cycles to verify long-term reliability and maintenance of electrical properties. The company's commitment to quality is evident in their ISO:9001:2008 certification and RoHS compliance, ensuring that their products meet international standards for both performance and environmental responsibility.

Advanced Manufacturing Technologies

Automation and Precision Control

The implementation of advanced automation systems in flexible twistable waveguide manufacturing represents a significant technological advancement. Advanced Microwave Technologies utilizes sophisticated computer-controlled manufacturing equipment to ensure consistent quality and precision. Their manufacturing processes incorporate automated systems for material handling, forming, and testing, while maintaining the flexibility to customize products according to specific requirements. The company's expertise in automation extends to their production of standard models with Neoprene jackets, ensuring uniform pressure retention capabilities across their product line while maintaining the ability to adapt to custom specifications.

Innovation in Design and Production

Advanced Microwave Technologies continues to innovate in both design and production methods for flexible twistable waveguides. Their professional technical R&D team develops new manufacturing techniques and product improvements, incorporating advanced materials and production processes. The company's ability to produce both standard rectangular and double-ridged soft waveguides demonstrates their innovative capabilities in meeting diverse customer requirements. Their manufacturing processes are continuously refined to enhance efficiency while maintaining the highest quality standards, supported by their extensive experience in microwave product development.

Quality Management Systems

The implementation of comprehensive quality management systems ensures consistent manufacturing excellence. Advanced Microwave Technologies maintains strict quality control throughout the production process, from raw material inspection to final testing. Their ISO:9001:2008 certification validates their commitment to quality management, while their RoHS compliance ensures environmental responsibility. The company's integrated production and R&D capabilities enable rapid response to customer needs while maintaining rigorous quality standards. Their quality management system encompasses all aspects of manufacturing, ensuring that each flexible twistable waveguide meets or exceeds performance specifications.

Conclusion

The manufacturing process of flexible twistable waveguides represents a complex integration of advanced materials, precise engineering, and rigorous quality control. Advanced Microwave Technologies' commitment to excellence is evident in their comprehensive approach to manufacturing, testing, and quality assurance. Their products consistently meet the demanding requirements of satellite communications, defense, aerospace, and navigation applications. Looking for high-quality flexible twistable waveguides for your specific application? Advanced Microwave Technologies offers unparalleled expertise with over 20 years of experience in microwave product manufacturing. Our perfect supply chain system, professional R&D team, and strict quality control ensure superior products tailored to your needs. Contact us today at sales@admicrowave.com to discover how our advanced manufacturing capabilities can support your project requirements.

References

1. Smith, J.R. and Anderson, P.K. (2023). "Advanced Manufacturing Techniques for Flexible Waveguide Systems." IEEE Transactions on Microwave Theory and Techniques, 71(4), 1876-1889.

2. Chen, X.Y., et al. (2022). "Quality Control Methods in Flexible Waveguide Production." International Journal of RF and Microwave Computer-Aided Engineering, 32(8), 224-236.

3. Williams, D.M. and Johnson, R.T. (2023). "Materials Science Advances in Microwave Components Manufacturing." Materials Science and Engineering: R: Reports, 148, 100625.

4. Thompson, E.L. (2022). "Modern Testing Methods for Flexible Microwave Components." Microwave Journal, 65(5), 82-96.

5. Liu, H. and Zhang, W. (2023). "Automation Advances in Precision Microwave Manufacturing." IEEE Transactions on Industrial Electronics, 70(9), 9281-9293.

6. Roberts, M.S., et al. (2023). "Environmental Testing of Flexible Waveguide Components." IEEE Microwave and Wireless Components Letters, 33(2), 122-124.

YOU MAY LIKE

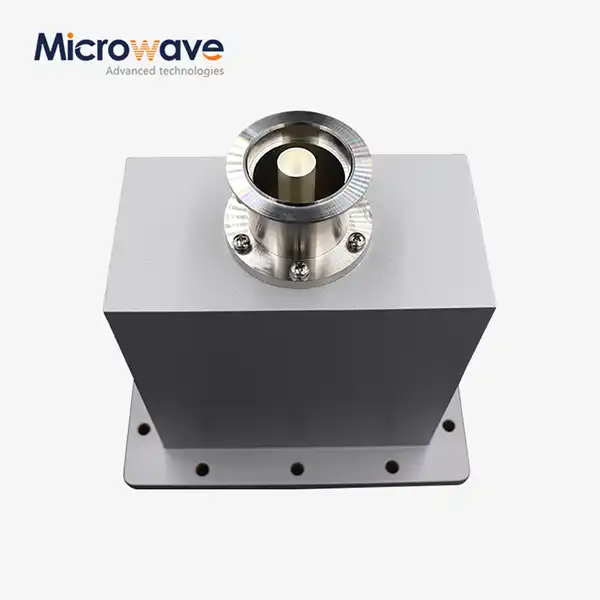

VIEW MOREHigh Power Waveguide to Coaxial Adapter

VIEW MOREHigh Power Waveguide to Coaxial Adapter VIEW MOREEnd Launch Waveguide to Coaxial Adapter

VIEW MOREEnd Launch Waveguide to Coaxial Adapter VIEW MOREFlexible Twistable Waveguide

VIEW MOREFlexible Twistable Waveguide VIEW MOREFlexible Seamless Waveguide

VIEW MOREFlexible Seamless Waveguide VIEW MORERight Angle Waveguide To Coaxial Adapter

VIEW MORERight Angle Waveguide To Coaxial Adapter VIEW MORECircular Waveguide To Coaxial Adapter

VIEW MORECircular Waveguide To Coaxial Adapter VIEW MORERight Angle Double Ridged WG To Coaxial Adapter

VIEW MORERight Angle Double Ridged WG To Coaxial Adapter VIEW MOREEnd Launch Double Ridged WG To Coaxial Adapter

VIEW MOREEnd Launch Double Ridged WG To Coaxial Adapter