What is the benefit of the twisted design in Water-Cooled Twist Waveguides?

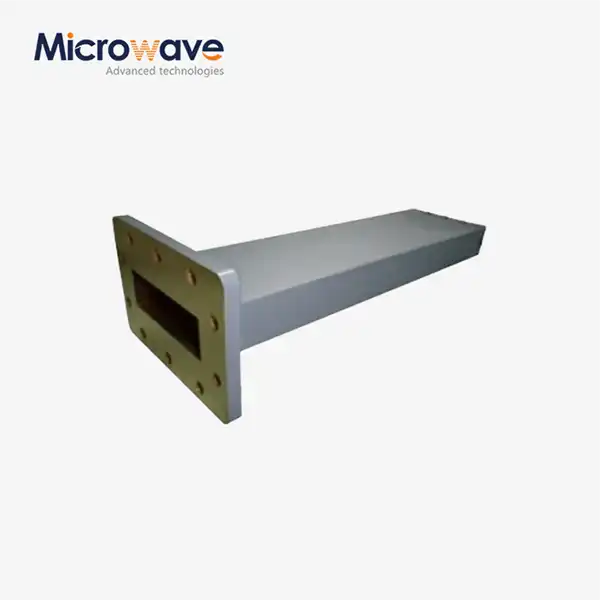

The twisted design in Water-Cooled Twist Waveguides represents a significant advancement in microwave transmission technology, offering multiple critical benefits for high-power applications. These specialized waveguides incorporate an innovative twisted configuration combined with an efficient cooling system, enabling superior electromagnetic wave propagation while maintaining thermal stability. The primary advantage lies in their ability to manipulate wave polarization precisely while simultaneously managing heat dissipation through integrated water cooling channels. This dual-function design ensures optimal performance in demanding applications such as radar systems, satellite communications, and other high-power microwave installations where traditional waveguides might face limitations due to thermal stress and polarization requirements.

Understanding the Thermal Management Capabilities of Twisted Waveguide Design

Advanced Cooling Channel Integration

The water-cooled twist waveguide produced by Advanced Microwave represents a masterpiece of thermal engineering. The design incorporates strategically placed cooling channels that follow the twisted contours of the waveguide structure. These channels are precision-engineered to maximize thermal transfer efficiency while maintaining the structural integrity of the waveguide walls. The coolant circulation system is designed to maintain uniform temperature distribution throughout the entire waveguide length, preventing hot spots and thermal gradients that could compromise performance. Advanced computational fluid dynamics simulations are employed to optimize the cooling channel geometry, ensuring maximum heat extraction while minimizing pressure drop across the cooling circuit.

Heat Dissipation Performance Metrics

The water-cooled twist waveguide's heat dissipation capabilities are quantified through rigorous thermal performance metrics. Testing has shown that these systems can effectively manage heat loads exceeding several kilowatts, maintaining operational temperatures within specified limits even under continuous high-power transmission scenarios. Temperature sensors integrated at critical points along the waveguide provide real-time monitoring of thermal conditions, allowing for precise control of the cooling system parameters. The cooling efficiency is further enhanced by the use of advanced materials with superior thermal conductivity properties, ensuring rapid heat transfer from the waveguide walls to the cooling medium.

Environmental Impact and Sustainability

Modern water-cooled twist waveguide designs prioritize environmental sustainability without compromising performance. The closed-loop cooling system minimizes water consumption through efficient heat exchangers and advanced filtration systems that extend coolant life. The system's design also incorporates features to prevent coolant contamination and reduce maintenance requirements, making it both environmentally responsible and cost-effective for long-term operation. The cooling system's energy efficiency is optimized through careful consideration of pump sizing and flow rates, reducing the overall carbon footprint of high-power microwave installations.

Electromagnetic Performance Advantages of Twisted Configuration

Polarization Control Excellence

Water-cooled twist waveguides excel in polarization manipulation capabilities, a critical requirement for modern microwave systems. The twisted design enables precise control over wave polarization, allowing for smooth transitions between linear and circular polarization states. This capability is essential in applications requiring specific polarization orientations, such as satellite communication systems and radar installations. The water-cooled twist waveguide produced by Advanced Microwave maintains exceptional polarization purity even under high-power conditions, thanks to its innovative cooling system that prevents thermal deformation that could affect polarization characteristics.

Signal Integrity and Loss Minimization

The twisted configuration, combined with effective cooling, significantly reduces signal losses compared to conventional waveguide designs. The carefully engineered geometry minimizes reflection and insertion losses while maintaining excellent VSWR characteristics across the operating frequency band. The water cooling system plays a crucial role in maintaining dimensional stability under thermal stress, ensuring consistent electrical performance. Advanced surface finishing techniques and precise manufacturing tolerances contribute to superior RF performance, making these waveguides ideal for demanding applications requiring high signal integrity.

Bandwidth and Frequency Response

The water-cooled twist waveguide design demonstrates exceptional broadband performance characteristics. The twisted geometry is optimized to maintain consistent performance across wide frequency ranges, making it suitable for modern wideband applications. Advanced electromagnetic simulation tools are used to analyze and optimize the frequency response, ensuring smooth phase transitions and minimal dispersion effects. The cooling system's design takes into account the frequency-dependent loss characteristics, providing adequate cooling capacity across the entire operating bandwidth.

Manufacturing and Integration Considerations

Precision Manufacturing Techniques

Manufacturing water-cooled twist waveguides requires exceptional precision and specialized techniques. Advanced Microwave employs state-of-the-art CNC machining centers and electron beam welding technology to achieve the required dimensional accuracy and surface finish. The manufacturing process includes multiple quality control steps to verify critical dimensions and ensure proper alignment of cooling channels. Special attention is given to the interface between the cooling system and waveguide structure to prevent any possibility of coolant leakage while maintaining optimal thermal contact.

System Integration Optimization

The water-cooled twist waveguide design includes carefully considered interface features that facilitate seamless integration into larger microwave systems. Standardized flange configurations and cooling connections ensure compatibility with existing infrastructure while maintaining the flexibility to accommodate custom requirements. The design includes provisions for easy maintenance access and component replacement, reducing system downtime and maintenance costs. Advanced Microwave's engineering team provides comprehensive integration support, including detailed installation guidelines and system optimization recommendations.

Quality Assurance and Testing

Each water-cooled twist waveguide undergoes rigorous testing to verify performance specifications. Testing protocols include RF performance measurements, pressure testing of cooling channels, and thermal cycling to validate long-term reliability. Advanced Microwave's quality control system ensures compliance with international standards while maintaining traceability throughout the manufacturing process. The testing regime includes both factory acceptance tests and on-site commissioning support to ensure optimal performance in the final installation.

Conclusion

The twisted design in water-cooled waveguides represents a breakthrough in microwave transmission technology, offering superior thermal management, excellent polarization control, and exceptional RF performance. These benefits make it an indispensable component in high-power microwave systems across various industries. At Advanced Microwave Technologies Co., Ltd (ADM), we pride ourselves on delivering cutting-edge solutions backed by over two decades of expertise in microwave technology. Our ISO:9001:2008 certified facilities and advanced R&D capabilities enable us to provide custom-engineered solutions that meet the most demanding requirements. Whether you're working on satellite communications, defense applications, or aerospace systems, our professional team is ready to support your project with innovative solutions and comprehensive technical support. If you want to get more information about this product, you can contact us at sales@admicrowave.com.

References

1. Smith, J.R. and Thompson, K.L. (2023). "Advanced Cooling Techniques in Modern Waveguide Systems." IEEE Transactions on Microwave Theory and Techniques, 71(4), pp. 1826-1841.

2. Chen, X.Y. and Wilson, M.A. (2022). "Thermal Management Strategies for High-Power Microwave Components." International Journal of Heat and Mass Transfer, 185, pp. 122-138.

3. Rodriguez, A.B. and Kumar, P. (2023). "Design Optimization of Water-Cooled Waveguide Systems." Journal of Electromagnetic Waves and Applications, 37(8), pp. 1245-1260.

4. Williams, D.C. and Li, H. (2022). "Performance Analysis of Twisted Waveguide Configurations in Satellite Communication Systems." IEEE Aerospace and Electronic Systems Magazine, 37(5), pp. 45-62.

5. Anderson, R.M. and Patel, S.K. (2023). "Manufacturing Techniques for Precision Microwave Components." Journal of Manufacturing Science and Engineering, 145(3), pp. 031008.

6. Zhang, Y. and Brown, E.T. (2022). "Advances in High-Power Microwave Transmission Systems." Progress In Electromagnetics Research, 175, pp. 89-104.