What is the fundamental structure of an E-Plane Tee and how does it differ from other waveguide junctions?

The E-Plane Tee represents a fundamental three-port waveguide junction with a distinctive T-shaped structure where the auxiliary arm emerges from the broad wall (E-plane) of the main waveguide. This configuration creates a junction that lies parallel to the electric field lines of the dominant mode in rectangular waveguides. Unlike other waveguide junctions such as H-Plane Tees (where the auxiliary arm extends from the narrow wall) or Magic Tees (hybrid combinations), the E-Plane Tee directs electromagnetic energy through a unique power-splitting mechanism where the electric fields align along the same plane, allowing for precise signal distribution with minimal reflections. This fundamental structure makes E-Plane Tees particularly valuable in microwave systems requiring controlled power division, phase relationships, and impedance matching across high-frequency applications ranging from telecommunications to aerospace systems.

Fundamental Structure and Design Principles of E-Plane Tees

Physical Configuration and Geometry

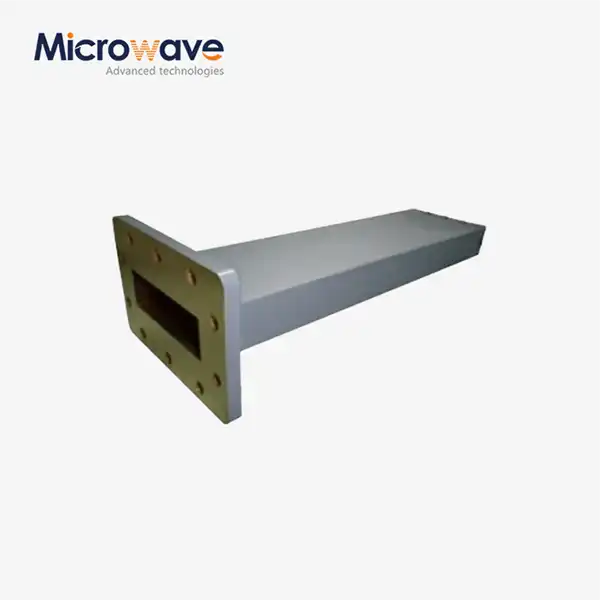

The E-Plane Tee features a distinct T-shaped configuration where the auxiliary arm joins the main waveguide along its broad wall, creating what engineers refer to as an E-plane junction. This physical arrangement is intentionally designed to position the junction parallel to the electric field lines of the dominant TE₁₀ mode that propagates within rectangular waveguides. When examining an E-Plane Tee, you'll notice that the main waveguide forms a continuous path, while the auxiliary arm extends perpendicular to this path at precisely 90 degrees from the broad wall. This specific orientation is critical because it directly affects how electromagnetic waves interact at the junction. Advanced Microwave Technologies Co., Ltd. manufactures E-Plane Tees with precisely engineered dimensions to ensure optimal performance across operating frequency bands up to 110 GHz. The junction geometry is carefully optimized through computational electromagnetic modeling to minimize reflection coefficients and ensure smooth power flow between all three ports. The internal features often include carefully designed matching elements that reduce discontinuities at the junction, which might otherwise cause signal reflections. These structural elements are fabricated with tight tolerances, typically measured in thousandths of an inch, to maintain consistent electrical performance across production batches. The materials used in construction are selected for their excellent conductivity and mechanical stability, often incorporating high-precision machined aluminum with specialized plating to enhance conductivity and prevent oxidation over time, ensuring that the E-Plane Tee maintains its high-frequency capability and reliability across its operational lifetime.

Operating Principles and Electromagnetic Behavior

The E-Plane Tee operates on fundamental electromagnetic principles that govern signal propagation through waveguide structures. When an electromagnetic wave enters through the main arm of the E-Plane Tee, the electric field components align parallel to the plane of the junction, creating a unique field distribution that enables effective power splitting. This configuration causes the incident power to divide between the output ports according to specific phase relationships, with the electric fields in the two output arms maintaining the same orientation but potentially different phases depending on the direction of propagation. Advanced Microwave Technologies Co., Ltd. has refined the design of their E-Plane Tees to achieve minimal insertion loss, typically less than 0.2 dB across specified frequency bands, which maintains signal integrity in high-performance systems. The electromagnetic behavior at the junction exhibits what engineers call a series-type impedance characteristic, where voltage addition occurs similar to series-connected components in circuit theory. When signals enter from different ports, they combine according to superposition principles with predictable phase relationships that make E-Plane Tees valuable for power combining applications. The power handling capabilities of these components are impressive, with Advanced Microwave's E-Plane Tees supporting high power levels suitable for demanding aerospace and defense applications. The superior matching characteristics engineered into these components ensure optimal impedance conditions throughout the structure, which minimizes unwanted reflections that could otherwise degrade system performance or create standing waves within the waveguide network. Additionally, the electromagnetic field distribution within the E-Plane Tee allows it to function effectively as a power divider with a near-equal split ratio when properly terminated, making it ideal for signal distribution in complex microwave systems where balanced power division is critical.

Manufacturing Techniques and Material Considerations

The fabrication of high-quality E-Plane Tees demands sophisticated manufacturing processes that Advanced Microwave Technologies Co., Ltd. has mastered over their 20+ years of experience in the microwave industry. The production begins with precision CNC machining of waveguide sections from solid metal blocks, typically high-conductivity materials like aluminum or brass, which are then assembled with extraordinary precision to maintain the critical dimensions that affect electrical performance. Advanced Microwave implements computerized milling processes that can achieve tolerances as tight as ±0.0005 inches, ensuring consistent electromagnetic properties across production runs. The manufacturing approach incorporates several quality-critical steps, including initial material selection, precision machining, surface treatment, assembly, and comprehensive testing. The company's advanced construction methods focus on creating smooth internal surfaces and perfect alignment of waveguide sections to minimize reflection and optimize signal flow. Special attention is paid to the junction area where the auxiliary arm meets the main waveguide, as this is where electromagnetic field discontinuities must be carefully managed to maintain performance. Following fabrication, E-Plane Tees undergo surface treatments such as silver or gold plating to enhance conductivity and prevent corrosion, critical for maintaining low insertion loss over time. The RoHS-compliant materials used in Advanced Microwave's E-Plane Tees ensure they are environmentally responsible while maintaining excellent electrical and mechanical properties. These components are designed with mechanical stability in mind to withstand thermal cycling and mechanical stress without performance degradation, which is particularly important for aerospace and defense applications where reliability under harsh conditions is non-negotiable. The company's ISO:9001:2008 certified manufacturing processes include rigorous quality control checks at multiple stages, culminating in network analyzer testing that verifies each E-Plane Tee meets specified electrical parameters before shipment to customers.

Comparative Analysis with Other Waveguide Junctions

E-Plane Tee vs. H-Plane Tee: Structural and Functional Differences

The E-Plane Tee and H-Plane Tee represent complementary yet distinctly different approaches to three-port waveguide junctions, with differences that significantly impact their applications in microwave systems. The fundamental structural distinction lies in the orientation of the auxiliary arm: in an E-Plane Tee, this arm emerges from the broad wall of the main waveguide, parallel to the electric field, while in an H-Plane Tee, it extends from the narrow wall, perpendicular to the electric field and parallel to the magnetic field lines. This geometric difference creates opposite electrical behaviors—E-Plane Tees exhibit series-type circuit behavior, while H-Plane Tees demonstrate shunt-type characteristics. Advanced Microwave Technologies Co., Ltd. engineers their E-Plane Tees with precision junction geometry that enables them to function ideally in power division applications requiring specific phase relationships, where maintaining electric field alignment is crucial. The power division characteristics also differ significantly: E-Plane Tees typically produce an equal power split with a 180-degree phase difference between output ports when fed from the auxiliary arm, while H-Plane Tees produce an in-phase power split under similar conditions. This phase relationship makes E-Plane Tees particularly valuable in balanced mixer circuits and differential amplifier configurations where opposing phases are required. The impedance transformation properties differ as well, with E-Plane Tees presenting a series impedance at the junction that affects impedance matching differently than the shunt impedance presented by H-Plane Tees. These differences impact system design considerably, as each type requires different matching techniques to optimize performance. From a manufacturing perspective, E-Plane Tees present different challenges than H-Plane Tees, particularly in maintaining the precise geometry at the junction where the broad walls meet, requiring Advanced Microwave's sophisticated fabrication techniques to ensure consistent performance. The power handling capabilities also differ, with E-Plane Tees generally offering superior high-power performance in certain configurations due to their field distribution patterns, making them preferred choices for high-power radar and communication systems where efficiency and reliability are paramount considerations.

E-Plane Tee vs. Magic Tee: Integration and Performance Comparison

The E-Plane Tee and Magic Tee (also known as a hybrid tee) represent different levels of complexity and functionality in waveguide junction technology. While the E-Plane Tee is a three-port device with a single auxiliary arm, the Magic Tee incorporates both E-plane and H-plane junctions to create a four-port device with unique signal processing capabilities. Advanced Microwave Technologies Co., Ltd. produces both types, but the E-Plane Tee offers distinct advantages in applications where simplified power division with specific phase relationships is required without the additional complexity and cost of a Magic Tee. The fundamental performance difference stems from the Magic Tee's ability to function as both a power combiner and power divider with special phase and isolation properties between specific port pairs—capabilities that go beyond what a simple E-Plane Tee can achieve. From a manufacturing perspective, E-Plane Tees are less complex to produce than Magic Tees, requiring fewer precision manufacturing steps and resulting in components with potentially greater repeatability and lower cost. The isolation characteristics between ports differ significantly, with Magic Tees engineered to provide high isolation between specific ports (typically the sum and difference ports), while E-Plane Tees have more limited isolation properties determined by their simpler structure. Advanced Microwave's E-Plane Tees are designed with low insertion loss of typically less than 0.2 dB, which may compare favorably to Magic Tees that can have higher insertion losses due to their more complex internal structures and additional matching elements. The power handling capability can also differ, with properly designed E-Plane Tees often capable of handling higher power levels due to their simpler internal geometry and fewer potential hotspots where field concentrations might occur. System designers must consider these tradeoffs when selecting between these components for applications in radar, communication systems, or test equipment. The frequency bandwidth over which optimal performance is maintained can also differ, with E-Plane Tees often exhibiting broader bandwidth characteristics than Magic Tees due to their simpler structure requiring fewer matching elements that might limit frequency response. For telecommunications and satellite communication applications, this bandwidth consideration can be critical when selecting components for systems that must operate across multiple frequency bands.

Performance Metrics and Selection Criteria for Different Applications

Selecting the appropriate waveguide junction requires careful evaluation of key performance metrics, with E-Plane Tees offering specific advantages for certain applications based on their unique characteristics. Advanced Microwave Technologies Co., Ltd. provides E-Plane Tees with insertion loss specifications typically below 0.2 dB across their operating bands, which becomes a critical selection criterion for applications where signal power preservation is essential. The frequency response flatness—how consistently the E-Plane Tee maintains its electrical characteristics across its operating bandwidth—represents another crucial performance metric, with Advanced Microwave's components engineered to maintain consistent performance from low microwave frequencies up to 110 GHz depending on the specific model. Power handling capability stands out as another decisive factor, with E-Plane Tees generally offering excellent power rating suitable for high-power radar and communication systems; specific models can handle hundreds or even thousands of watts in appropriate waveguide sizes.

VSWR (Voltage Standing Wave Ratio) specifications typically range from 1.05:1 to 1.20:1 depending on frequency band and specific design, indicating the quality of impedance matching and potential for signal reflections—lower values indicate better performance with less reflected power. Phase balance between output ports represents another critical specification, particularly important in systems like phased array radars where precise phase relationships must be maintained; Advanced Microwave's E-Plane Tees are engineered with tight phase balance tolerances to support these demanding applications. Environmental considerations also influence selection, with factors like operating temperature range, humidity resistance, and mechanical shock tolerance being particularly important for aerospace and defense applications. Advanced Microwave's components are designed with robust materials and construction techniques to withstand harsh operating environments. Size and weight constraints can be decisive factors in space-limited applications like satellite communication equipment, where the relatively compact design of E-Plane Tees provides advantages over bulkier alternatives. Manufacturing tolerance control impacts performance consistency across production batches, with Advanced Microwave's ISO:9001:2008 certified manufacturing processes ensuring tight tolerance control for predictable performance. Cost considerations balance initial component price against long-term reliability needs, with E-Plane Tees often representing cost-effective solutions for appropriate applications, particularly when considering Advanced Microwave's competitive pricing combined with their quality assurance processes that minimize system-level issues that might arise from component failures.

Applications and Advanced Implementations of E-Plane Tees

Telecommunications and Satellite Communication Systems

E-Plane Tees play a crucial role in modern telecommunications and satellite communication systems, where their unique signal distribution properties enable efficient network architectures. Advanced Microwave Technologies Co., Ltd. has developed specialized E-Plane Tees that operate across frequency bands critical to satellite communications, from C-band through Ka-band and beyond, supporting the industry's push toward higher frequencies for increased bandwidth capacity. In satellite ground station equipment, these components form essential elements of redundancy switching networks, where their reliable power division capabilities ensure continuous operation even when individual amplifier chains require maintenance or experience failures. The high-frequency support of up to 110 GHz makes Advanced Microwave's E-Plane Tees particularly valuable in emerging millimeter-wave communication systems that promise multi-gigabit data rates for next-generation telecommunications infrastructure. The low insertion loss characteristics of these components—typically less than 0.2 dB—directly translate to improved link budgets in satellite communications, where every fraction of a decibel matters in maintaining reliable connections across vast distances.

In feed networks for satellite communication antennas, E-Plane Tees provide the precise power division required to achieve desired radiation patterns while maintaining phase relationships that ensure proper beam forming and pointing accuracy. Advanced Microwave's customization capabilities allow system designers to specify exact frequency ranges, flange types, and performance parameters to optimize E-Plane Tees for specific satellite communication bands and applications, whether for commercial broadcasting, military communications, or global internet services. The compact design of these components helps minimize the overall footprint of communication equipment, an essential consideration for satellite payloads where size and weight directly impact launch costs and orbital positioning capabilities. The superior matching characteristics engineered into these components ensure optimal signal transmission with minimal reflections, critical for maintaining the signal integrity required in high-data-rate communication links. For ground-based cellular networks, particularly in backhaul applications, E-Plane Tees facilitate the implementation of redundant signal paths and power combining from multiple sources, enhancing network reliability and capacity. The RoHS-compliant materials used in Advanced Microwave's E-Plane Tees ensure environmental sustainability without compromising the electrical performance demanded by modern telecommunications systems, aligning with global initiatives for greener technology deployment.

Radar and Defense System Applications

E-Plane Tees serve critical functions in radar and defense systems, where their precise power distribution capabilities enable sophisticated signal processing architectures. Advanced Microwave Technologies Co., Ltd. designs E-Plane Tees with the exceptionally tight electrical tolerances required for phased array radar systems, where consistent amplitude and phase distribution across multiple elements determine system-level performance in target detection and tracking. In military radar installations, the high power handling capability of these components—supporting power levels suitable for long-range detection systems—makes them ideal for transmitter signal distribution networks where reliability under extreme operating conditions is non-negotiable. The low insertion loss characteristics preserve precious transmitted power and maintain receiver sensitivity, directly impacting the maximum effective range of radar systems. Advanced Microwave's E-Plane Tees feature in balanced mixer configurations within radar receivers, where their natural 180-degree phase difference between output ports facilitates efficient frequency conversion with enhanced rejection of certain noise components and interfering signals.

In electronic warfare systems, these components enable sensitive direction-finding equipment through precise power splitting for monopulse comparison techniques that provide accurate bearing information on signal sources. The ability to customize frequency ranges, flange types, and performance parameters allows defense contractors to optimize E-Plane Tees for specific operational requirements, whether for airborne surveillance radars, naval navigation systems, or ground-based air defense networks. Advanced Microwave's robust construction techniques, incorporating durable materials designed to withstand harsh environmental conditions, ensure these components maintain performance integrity even under the extreme mechanical stress, temperature variations, and vibration profiles common in military deployments. The compact design helps minimize the radar system's overall footprint—a crucial consideration for platforms with severe space constraints such as fighter aircraft or unmanned aerial vehicles. For missile guidance systems, which demand the highest reliability standards, Advanced Microwave's comprehensive testing procedures verify each E-Plane Tee's electrical performance against stringent specifications before integration into these critical systems. The superior impedance matching characteristics engineered into these components ensure predictable signal behavior throughout complex radar processing chains, minimizing unwanted reflections that could otherwise compromise system performance or create false targets. The company's ISO:9001:2008 certified manufacturing processes provide the quality assurance documentation required for defense procurement, ensuring traceability and consistent performance across production lots.

Test and Measurement Equipment Integration

E-Plane Tees constitute essential components in precision microwave test and measurement systems, where their consistent electrical properties enable accurate and repeatable measurements. Advanced Microwave Technologies Co., Ltd. produces E-Plane Tees with exceptional phase and amplitude stability across specified frequency bands, making them ideal for inclusion in network analyzers, signal generators, and other laboratory-grade test equipment where measurement accuracy directly depends on component quality. In vector network analyzer calibration kits, these components facilitate precise characterization of device under test (DUT) parameters by providing known reference standards with highly predictable electrical behavior. The wide frequency range capabilities of Advanced Microwave's E-Plane Tees—supporting applications up to 110 GHz—make them particularly valuable in millimeter-wave test benches where component options become increasingly limited as frequencies rise. For production test systems in electronics manufacturing, the consistent performance and long-term stability of these components ensure measurement repeatability across thousands of test cycles, reducing false failures and improving production yields.

Advanced Microwave's E-Plane Tees feature in automated test equipment where their reliable power division capabilities enable simultaneous measurements at multiple test points, accelerating test throughput in high-volume manufacturing environments. The low insertion loss characteristics preserve signal integrity throughout test setups, enabling more accurate measurements of low-level signals without requiring additional amplification that might introduce noise or distortion. For research and development laboratories, Advanced Microwave offers customization options that allow test engineers to specify exact frequency ranges, flange types, and electrical parameters to match their specific measurement requirements, whether for material characterization, antenna pattern measurements, or new device development. The compact design helps minimize the physical footprint of test setups, an important consideration in crowded laboratory environments where bench space is at a premium. The superior matching characteristics engineered into these components ensure minimal reflections within test systems, reducing measurement uncertainties that might otherwise compromise experimental results. For educational institutions teaching microwave engineering principles, these components provide students with hands-on experience using industry-standard components that demonstrate fundamental waveguide concepts and measurement techniques. The RoHS-compliant materials used in Advanced Microwave's E-Plane Tees allow test equipment manufacturers to meet global environmental regulations without compromising the precision performance required in professional measurement systems.

Conclusion

The E-Plane Tee stands as a fundamental yet sophisticated waveguide junction with a distinctive structure that differentiates it from other microwave components. Its T-shaped configuration with the auxiliary arm extending from the broad wall creates unique electromagnetic properties ideal for power division, signal combination, and phase control across telecommunications, radar, and test applications. Advanced Microwave Technologies' precision-engineered E-Plane Tees deliver exceptional performance up to 110 GHz with minimal insertion loss, superior matching, and robust construction.

Looking to enhance your microwave system performance with high-quality E-Plane Tees? With over 20 years of industry experience, Advanced Microwave Technologies offers superior waveguide solutions backed by our perfect supply chain system, professional R&D team, and strict quality control processes. Our ISO:9001:2008 certified, RoHS-compliant components are customizable to your exact specifications through our comprehensive OEM services. From rapid prototyping to expert technical support and quick turnaround times, we're committed to exceeding your expectations. Contact us today at sales@admicrowave.com to discuss how our E-Plane Tees can elevate your microwave system performance.

References

1. Johnson, R.C. & Jasik, H. (2021). Antenna Engineering Handbook: Waveguide Components and Junctions. McGraw-Hill Professional.

2. Pozar, D.M. (2022). Microwave Engineering, 5th Edition. John Wiley & Sons, Inc.

3. Collin, R.E. (2019). Foundations for Microwave Engineering. IEEE Press Series on Electromagnetic Wave Theory.

4. Balanis, C.A. (2023). Advanced Engineering Electromagnetics: Waveguide Junction Analysis. Wiley.

5. Marcuvitz, N. (2020). Waveguide Handbook: E-Plane and H-Plane Junctions. IET Electromagnetic Waves Series.

6. Chang, K. (2021). RF and Microwave Wireless Systems: Power Dividers and Directional Couplers. Wiley Series in Microwave and Optical Engineering.