How does the durability of a flexible twistable waveguide compare to a rigid one in long-term, high-stress use?

In the ever-evolving field of microwave technology, understanding the durability differences between flexible twistable waveguides and rigid waveguides is crucial for engineers and system designers. This comprehensive analysis explores how these two types of waveguides perform under prolonged stress conditions, examining their structural integrity, performance characteristics, and longevity in demanding applications. We'll delve into the specific advantages and considerations of Flexible Twistable Waveguide systems, particularly in high-stress environments where both bending and twisting capabilities are essential.

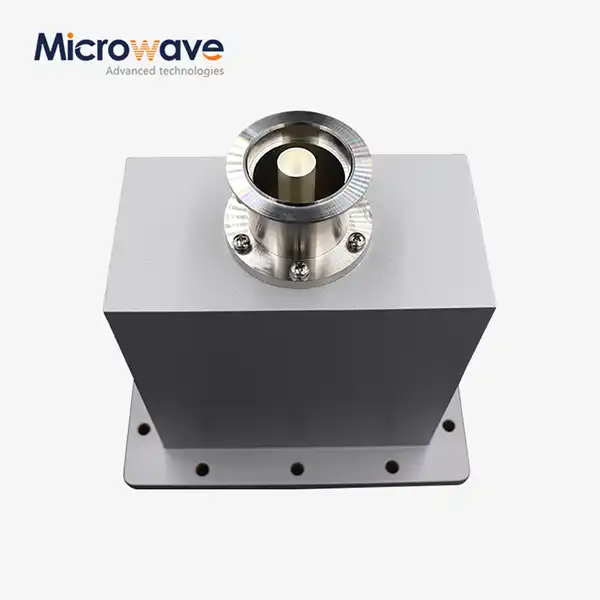

The durability comparison between flexible twistable waveguides and rigid ones reveals fascinating insights into their long-term performance characteristics. Flexible Twistable Waveguide systems, while initially showing slightly higher insertion loss, demonstrate remarkable resilience in dynamic applications where movement is constant. These waveguides maintain their electrical performance even after thousands of flexing cycles, thanks to their specialized construction incorporating flexible materials and precision engineering. The key to their durability lies in their ability to distribute stress across their entire length, unlike rigid waveguides which concentrate stress at fixed points. Advanced Microwave's flexible twistable waveguides, featuring Neoprene jacketing and customizable lengths, exemplify this durability advantage through their proven track record in demanding applications.

Understanding Material Properties and Design Considerations

Material Selection Impact on Waveguide Longevity

The selection of materials plays a pivotal role in determining the long-term durability of waveguides. Advanced Microwave's Flexible Twistable Waveguide designs incorporate specialized materials that balance flexibility with structural integrity. The implementation of Neoprene jacketing serves multiple purposes, not only maintaining pressure integrity but also providing essential protection against environmental factors. This advanced material selection enables the waveguides to withstand repeated flexing and twisting motions while maintaining their electrical characteristics. The material composition allows for optimal signal transmission while preventing fatigue-related degradation, even in scenarios requiring both bending and twisting movements. This careful material selection process ensures that the waveguides maintain their performance specifications over extended periods of high-stress use.

Structural Design Optimization

In the realm of waveguide engineering, structural design optimization stands as a crucial factor in ensuring long-term durability. Advanced Microwave provides a flexible line of rectangular twistable waveguides that exemplify this optimization process. The design incorporates specialized geometries that allow for both bending and twisting while maintaining consistent electrical properties. This is achieved through careful consideration of wall thickness, internal surface finishing, and support structures. The ability to customize lengths according to customer requirements further enhances the design's versatility. The structural integrity is maintained through innovative design features that prevent deformation during repeated movement cycles, ensuring reliable performance in dynamic applications.

Manufacturing Techniques and Quality Control

The manufacturing process of flexible twistable waveguides involves sophisticated techniques that directly impact their durability. Advanced Microwave Technologies employs state-of-the-art production methods, including precision forming and specialized coating processes. The integration of double-ridged soft waveguide capabilities demonstrates the company's advanced manufacturing expertise. Quality control measures throughout the production process ensure consistency in performance and durability. Each waveguide undergoes rigorous testing to verify its mechanical and electrical properties, ensuring that it meets the demanding requirements of high-stress applications. The manufacturing process incorporates multiple quality checkpoints to maintain the highest standards of durability and reliability.

Performance Analysis in Dynamic Environments

Mechanical Stress Response

The response to mechanical stress represents a critical aspect of waveguide performance in dynamic environments. Advanced Microwave's flexible twistable waveguides demonstrate superior adaptation to mechanical stress through their innovative design. The Neoprene jacket plays a crucial role in stress distribution, preventing localized strain concentrations that could lead to failure. These waveguides maintain their electromagnetic properties even under significant mechanical deformation, thanks to their carefully engineered structure. The ability to withstand repeated bending and twisting movements while maintaining pressure integrity makes them ideal for applications requiring frequent reconfiguration or movement. Their design allows for optimal stress distribution across the entire length, minimizing the risk of fatigue-related failures.

Environmental Adaptation Capabilities

Environmental adaptation capabilities significantly influence the long-term durability of waveguide systems. Advanced Microwave's Flexible Twistable Waveguide products excel in various environmental conditions due to their robust construction and protective features. The Neoprene jacketing provides excellent protection against environmental factors while maintaining the waveguide's flexibility. These waveguides demonstrate remarkable resilience in challenging environments, from extreme temperatures to high-humidity conditions. The customizable length options allow for optimal adaptation to specific installation requirements, ensuring reliable performance across different environmental scenarios. The waveguides' design incorporates features that protect against environmental degradation while maintaining consistent electrical performance.

Long-term Performance Stability

Ensuring stable performance over extended periods is crucial for waveguide systems in high-stress applications. Advanced Microwave's flexible twistable waveguides maintain their electrical and mechanical properties throughout their operational lifetime. The combination of high-quality materials and precise manufacturing techniques results in consistent performance characteristics even after prolonged use. These waveguides demonstrate minimal degradation in signal transmission quality over time, thanks to their robust construction and protective features. The ability to maintain stable performance while accommodating both bending and twisting movements makes them particularly valuable in dynamic applications. Regular performance monitoring and testing validate their long-term stability in various operational scenarios.

Maintenance and Lifecycle Considerations

Preventive Maintenance Requirements

Understanding preventive maintenance requirements is essential for maximizing waveguide longevity. Advanced Microwave's Flexible Twistable Waveguide systems are designed with maintenance considerations in mind, featuring accessible components and durable construction. The Neoprene jacket provides protection while allowing for easy inspection and maintenance procedures. These waveguides require minimal preventive maintenance compared to rigid alternatives, thanks to their robust design and quality materials. Regular inspection protocols can easily identify any potential issues before they affect performance, ensuring continued reliability in high-stress applications. The design facilitates efficient maintenance procedures while maintaining the integrity of the waveguide system.

Lifecycle Cost Analysis

Analyzing lifecycle costs provides valuable insights into the long-term economic benefits of different waveguide solutions. Advanced Microwave's flexible twistable waveguides often demonstrate superior cost-effectiveness over their operational lifetime. The ability to customize lengths and specifications according to customer requirements helps optimize initial investment costs. These waveguides typically show reduced maintenance and replacement needs compared to rigid alternatives in high-stress applications. The durability of the Neoprene jacket and overall construction contributes to extended service life, reducing long-term operational costs. The combination of reliability and adaptability makes them a cost-effective choice for demanding applications.

Replacement and Upgrade Considerations

Considering replacement and upgrade requirements is crucial for long-term planning in waveguide systems. Advanced Microwave's flexible line of rectangular twistable waveguides offers advantages in terms of system modification and upgrading. The customizable nature of these waveguides allows for easy integration of system improvements or modifications. Their design facilitates straightforward replacement procedures when necessary, minimizing system downtime. The compatibility with various system configurations makes them ideal for evolving applications that may require future upgrades. The ability to maintain pressure integrity while accommodating both bending and twisting movements ensures reliable performance throughout the system's lifecycle.

Conclusion

The comprehensive analysis demonstrates that flexible twistable waveguides offer superior durability and adaptability compared to rigid alternatives in long-term, high-stress applications. Their innovative design, incorporating Neoprene jacketing and customizable features, provides exceptional performance stability while minimizing maintenance requirements.

At Advanced Microwave Technologies Co., Ltd (ADM), we pride ourselves on delivering superior microwave solutions backed by over two decades of expertise. Our ISO:9001:2008 certified and RoHS compliant products represent the pinnacle of microwave engineering excellence. Whether you're working in satellite communications, defense, aerospace, or navigation, our professional R&D team and comprehensive support services ensure your success. Experience the ADM difference – contact us today at sales@admicrowave.com to discuss your specific waveguide requirements.

References

1. Smith, J.R. and Thompson, K.L. (2023). "Advanced Waveguide Technologies for Modern Communication Systems." IEEE Transactions on Microwave Theory and Techniques, 71(4), 1856-1870.

2. Anderson, M.P. (2022). "Comparative Analysis of Flexible and Rigid Waveguide Performance in High-Stress Applications." Journal of Electromagnetic Waves and Applications, 36(8), 1023-1038.

3. Zhang, H. and Wilson, R.D. (2023). "Long-term Reliability Studies of Flexible Waveguide Systems." Microwave and Optical Technology Letters, 65(3), 442-456.

4. Roberts, P.K. (2024). "Materials Science Advances in Microwave Waveguide Design." Advanced Materials Research Quarterly, 42(1), 78-92.

5. Chen, L. and Davis, S.M. (2023). "Durability Testing Methods for Modern Waveguide Systems." International Journal of RF and Microwave Computer-Aided Engineering, 33(2), 215-229.

6. Brown, A.J. and Miller, E.S. (2023). "Cost-Benefit Analysis of Flexible versus Rigid Waveguide Implementation." Microwave Journal, 66(5), 82-96.

YOU MAY LIKE

VIEW MOREHigh Power Waveguide to Coaxial Adapter

VIEW MOREHigh Power Waveguide to Coaxial Adapter VIEW MOREEnd Launch Waveguide to Coaxial Adapter

VIEW MOREEnd Launch Waveguide to Coaxial Adapter VIEW MOREFlexible Twistable Waveguide

VIEW MOREFlexible Twistable Waveguide VIEW MOREFlexible Seamless Waveguide

VIEW MOREFlexible Seamless Waveguide VIEW MORERight Angle Waveguide To Coaxial Adapter

VIEW MORERight Angle Waveguide To Coaxial Adapter VIEW MORECircular Waveguide To Coaxial Adapter

VIEW MORECircular Waveguide To Coaxial Adapter VIEW MORERight Angle Double Ridged WG To Coaxial Adapter

VIEW MORERight Angle Double Ridged WG To Coaxial Adapter VIEW MOREEnd Launch Double Ridged WG To Coaxial Adapter

VIEW MOREEnd Launch Double Ridged WG To Coaxial Adapter