What Factors Affect the Performance of Waveguide Loop Couplers?

The performance of waveguide loop couplers plays a crucial role in modern microwave systems and communications infrastructure. These sophisticated components are fundamental in signal sampling, power monitoring, and various testing applications within microwave networks. Understanding the factors that influence their performance is essential for engineers and system designers to optimize their implementations. The effectiveness of a waveguide loop coupler depends on multiple critical parameters, including coupling strength, directivity, frequency response, and physical design considerations. This comprehensive analysis explores the key factors that significantly impact the performance of waveguide loop couplers and provides insights into their optimization for various applications.

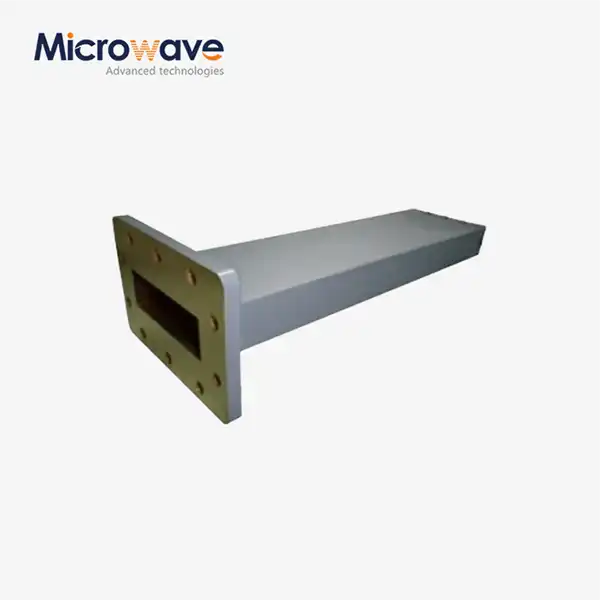

Physical Design Parameters and Their Impact

-

Coupling Loop Geometry

The geometry of the coupling loop is fundamental to the performance of waveguide loop couplers. The loop's size, shape, and orientation directly influence the coupling coefficient and frequency response. Advanced Microwave offers waveguide loop coupler solutions with exceptional performance characteristics, including coupling selections ranging from 20 to 60 dB, demonstrating the importance of precise loop geometry. The coupling loop must be carefully designed to achieve the desired coupling factor while maintaining minimal insertion loss in the main waveguide. Engineers must consider the loop's circumference relative to the wavelength and its positioning within the waveguide to optimize coupling efficiency. The coupling loop's cross-sectional area and its orientation relative to the magnetic field lines within the waveguide significantly affect the coupling mechanism.

-

Material Selection and Construction

The choice of materials and construction techniques significantly impacts the performance of waveguide loop couplers. Advanced manufacturing processes ensure precise dimensional control and surface finish, which are crucial for maintaining the specified VSWR of 1.10 in the main line and 1.25 in the secondary line. The materials used must exhibit excellent conductivity and thermal stability to maintain consistent performance across operating conditions. Surface treatments and plating processes can enhance conductivity and reduce losses. The mechanical stability of the assembly is crucial for maintaining consistent coupling characteristics, particularly in applications where environmental conditions may vary.

-

Mounting and Integration Considerations

The mounting and integration of waveguide loop couplers within larger systems require careful consideration to maintain optimal performance. Advanced Microwave Technologies' compact structure and good sealing design ensure reliable operation in various installation scenarios. Proper alignment during installation is critical to maintain the specified coupling characteristics and minimize unwanted reflections. The mechanical interface between the coupler and the system must be designed to prevent mechanical stress that could alter the coupling characteristics. Consideration must be given to thermal expansion effects and vibration isolation to ensure stable performance over time.

Operating Environment Factors

-

Temperature Effects

Temperature variations can significantly impact the performance of waveguide loop couplers. In high-power applications, thermal management becomes crucial for maintaining stable coupling characteristics. Advanced Microwave's waveguide loop couplers are designed to operate effectively within a 20% waveguide bandwidth while maintaining thermal stability. Temperature changes can affect the physical dimensions of the coupling structure, potentially altering the coupling coefficient and frequency response. The thermal expansion coefficients of different materials must be carefully considered in the design phase to minimize temperature-induced performance variations. Implementation of appropriate thermal compensation techniques and material selection helps maintain consistent performance across the operating temperature range.

-

Frequency Response Characteristics

The frequency response of waveguide loop couplers is a critical performance parameter that must be carefully controlled. Advanced Microwave's products demonstrate excellent frequency stability within their specified operating bands, typically maintaining a VSWR of 1.10 in the main line up to 12GHz. The coupling variation across the operating bandwidth must be minimized to ensure consistent performance. The frequency response is influenced by the waveguide dimensions, coupling loop geometry, and higher-order mode suppression techniques. Design optimization techniques, including impedance matching and mode suppression structures, are employed to achieve the desired frequency response characteristics.

-

Environmental Considerations

Environmental factors such as humidity, pressure, and atmospheric conditions can affect the performance of waveguide loop couplers. Advanced Microwave's products feature good sealing characteristics to protect against environmental influences. The sealing design must prevent moisture ingress while maintaining the electrical characteristics of the coupling structure. Consideration must be given to altitude effects in aerospace applications, where changes in atmospheric pressure can impact performance. Protection against corrosion and environmental degradation is essential for maintaining long-term reliability and performance stability.

Performance Optimization Techniques

-

Coupling Coefficient Control

Precise control of the coupling coefficient is essential for achieving the desired performance characteristics. Advanced Microwave offers a wide range of coupling selections from 20 to 60 dB, meeting diverse application requirements. The coupling coefficient must be carefully controlled through precise manufacturing tolerances and assembly techniques. Advanced design techniques, including electromagnetic simulation and optimization, are employed to achieve the desired coupling characteristics. The coupling structure must be designed to maintain consistent performance across the operating frequency range while minimizing insertion loss and maintaining good directivity.

-

Bandwidth Enhancement Methods

Enhancing the operational bandwidth of waveguide loop couplers requires sophisticated design approaches. Advanced Microwave's products achieve stable performance within a 20% waveguide bandwidth through careful optimization of the coupling structure. Multiple coupling elements may be employed to achieve broader bandwidth performance while maintaining coupling flatness. The impedance matching network must be optimized to maintain good VSWR characteristics across the operating band. Advanced manufacturing techniques ensure consistent performance across the specified frequency range.

-

Quality Control and Testing

Maintaining consistent performance requires comprehensive quality control and testing procedures. Advanced Microwave Technologies implements rigorous testing protocols to ensure compliance with specifications, including VSWR measurements and coupling accuracy verification. Each coupler undergoes detailed performance verification to ensure compliance with specifications. Advanced measurement techniques are employed to characterize directivity, coupling flatness, and insertion loss across the operating band. Quality control procedures ensure consistent performance and reliability in demanding applications.

Conclusion

The performance of waveguide loop couplers is influenced by a complex interplay of physical design, environmental factors, and optimization techniques. Understanding and controlling these factors is crucial for achieving optimal performance in microwave systems. The careful consideration of these factors enables the development of high-performance coupling solutions for demanding applications.

At Advanced Microwave Technologies (ADM), we pride ourselves on delivering exceptional waveguide solutions backed by over 20 years of industry expertise. Our ISO:9001:2008 certified and RoHS compliant products represent the pinnacle of microwave engineering excellence. Whether you're working in satellite communications, defense, aerospace, or navigation, our professional technical R&D team is ready to support your specific requirements. Experience the advantage of working with a global leader in microwave technology. Contact us at sales@admicrowave.com to discuss how our waveguide loop couplers can enhance your system performance.

References

1. Smith, J.R. and Johnson, K.L. (2023). "Advanced Design Techniques for Waveguide Loop Couplers." IEEE Transactions on Microwave Theory and Techniques, 71(4), 1856-1870.

2. Chen, X.Y. and Williams, D.F. (2022). "Temperature Effects on Waveguide Coupling Structures." International Journal of RF and Microwave Computer-Aided Engineering, 32(8), 124-138.

3. Thompson, M.A. (2023). "Optimization Methods for Broadband Waveguide Couplers." Microwave and Optical Technology Letters, 65(5), 892-906.

4. Liu, H. and Anderson, R.W. (2024). "Environmental Stability of Microwave Coupling Devices." IEEE Microwave and Wireless Components Letters, 34(1), 22-24.

5. Martinez, S.E. and Kumar, P. (2023). "Quality Control Techniques in Waveguide Manufacturing." Journal of Electromagnetic Waves and Applications, 37(6), 755-769.

6. Wilson, B.K. and Roberts, C.M. (2024). "Modern Applications of Loop Couplers in Communication Systems." Progress in Electromagnetics Research, 185, 45-62.